Exclusive Neuroject Article: The development of smart warehouse in construction is a beacon of transformational potential in the dynamic field of construction, where accuracy and efficiency rule supreme. The construction industry, which is renowned for its sophisticated supply chains and logistics, is on the verge of a dramatic change that will be fueled by the introduction of intelligence into every aspect of the sector.

The need to improve resource management, reduce downtime, and streamline operations has never been more critical as construction projects grow in complexity and size. Intelligent hubs that leverage the Internet of Things (IoT), automation, and data analytics are taking the role of traditional warehouses, with their human operations and restrictions.

This article explores the panorama of smart warehouse in construction currently under development, identifying the technologies, advantages, difficulties, and best practices that characterize this paradigm shift. Join us as we investigate how, one warehouse at a time, the confluence of building know-how and cutting-edge technology is changing the way we build.

Table of Contents

Introduction

The incorporation of cutting-edge technologies is changing traditional methods in the dynamic construction sector and opening the door for previously unheard-of advances in productivity and efficiency. The idea of “Smart Warehouses,” a paradigm shift that is altering how building supplies are managed, stored, and distributed, is one such disruptive movement.

Construction warehouses have historically been associated with logistical difficulties, labor-intensive inventory management, and manual tracking procedures. A new era of innovation, however, has emerged with the arrival of the Fourth Industrial Revolution, driven by technologies like the Internet of Things (IoT), sensor networks, real-time data analytics, and automation. By combining these technologies, smart warehouse in construction will be built that provide real-time inventory visibility, expedite supply chain operations, reduce downtime, and improve worker safety.

The switch to smart warehouse in construction industry represents more than just a change in technology; it also represents a fundamental shift in the way projects are carried out. The evolution of building warehouses will be examined, along with the essential technologies enabling smart warehouse in construction, their numerous advantages, and case studies of successful implementation. Additionally, it will look at the difficulties adoption may present for construction companies and offer suggestions for a smooth transition.

As we continue our investigation into smart warehouse in construction for the construction industry, it becomes clear that adopting these technologies is not just a choice but rather a need for businesses that want to stay competitive and adaptable in a sector that is always changing. Construction companies can achieve previously unheard-of levels of efficiency by adopting the ideas and recommendations provided in this manual.

The Evolution of Smart Warehouse in Construction

Construction warehouses have changed significantly from being basic storage areas to being crucial parts of an extremely complex supply chain ecology. Technology improvements, shifting business dynamics, and the desire for greater efficiency in the construction industry have all contributed to the evolution of these warehouses.

Construction warehouses used to be as basic storage facilities for tools and supplies used in the industry. Physical space was prioritized, with process optimization and data use receiving little attention. However, the demand for effective warehouse operations became clear as the construction sector got more competitive and project deadlines tightened.

Construction warehouse development saw a sea change with the introduction of technology. Inventory tracking and management started to become more efficient with the introduction of digital instruments like barcode systems and inventory management software. This improved supply management for construction organizations lowered waste, and increased overall project effectiveness.

Smart warehouse in construction underwent even more change with the growth of the Internet of Things (IoT). Real-time tracking of supplies and machinery was made possible by sensors and RFID (Radio-Frequency Identification) technology. By reducing theft and illegal access, strengthening security in addition to improving inventory accuracy. Construction managers could now make educated judgments about material replenishment and distribution because of the data these technologies collected.

Key Technologies Transforming Smart Warehouses

With the incorporation of smart technologies into warehouse operations, the construction industry has recently experienced a dramatic revolution. The management, storage, and distribution of building materials and supplies have been completely transformed by these technologies. The creation of smart warehouse in construction that are more effective, precise, and responsive to market demands has been made possible by the rise of the Internet of Things (IoT), cutting-edge sensors, Radio Frequency Identification (RFID), and automation systems.

Internet of Things (IoT) and Sensor Networks

The Internet of Things (IoT), a network of connected devices and sensors that interact and exchange data in real-time, is at the center of the revolution in smart warehouse in construction. IoT is essential for keeping track of many characteristics in construction warehouses, including temperature, humidity, and stock levels. Warehouse managers can learn about the conditions and statuses of the commodities being stored thanks to sensors that are implanted throughout the facility and collect data.

IoT-enabled temperature and humidity sensors, for instance, make sure that delicate building materials, like cement and adhesives, are maintained in the best conditions possible, preventing quality degradation. Additionally, decreasing overstocking and stockouts through real-time inventory tracking using IoT sensors results in better inventory management and lower expenses.

Suggested articles to read: The Ultimate Guide to IoT Sensor in 2024 | Smart Construction: Top 7 IoT Applications

Radio Frequency Identification (RFID)

Inventory management in smart warehouse in construction has been significantly changed by RFID technology. Construction supplies and materials can be identified and tracked remotely via radio waves thanks to RFID tags that are connected to them. Materials passing through RFID-equipped gateways automatically acquire and record information about their movement, location, and quantity.

With the help of this technology, the visibility of the supply chain is improved, and manual tracking takes less time and effort. Now that certain goods can be precisely located within huge warehouses, retrieval times can be shortened and project delays can be minimized. RFID also plays a vital part in boosting security by avoiding theft and illegal access.

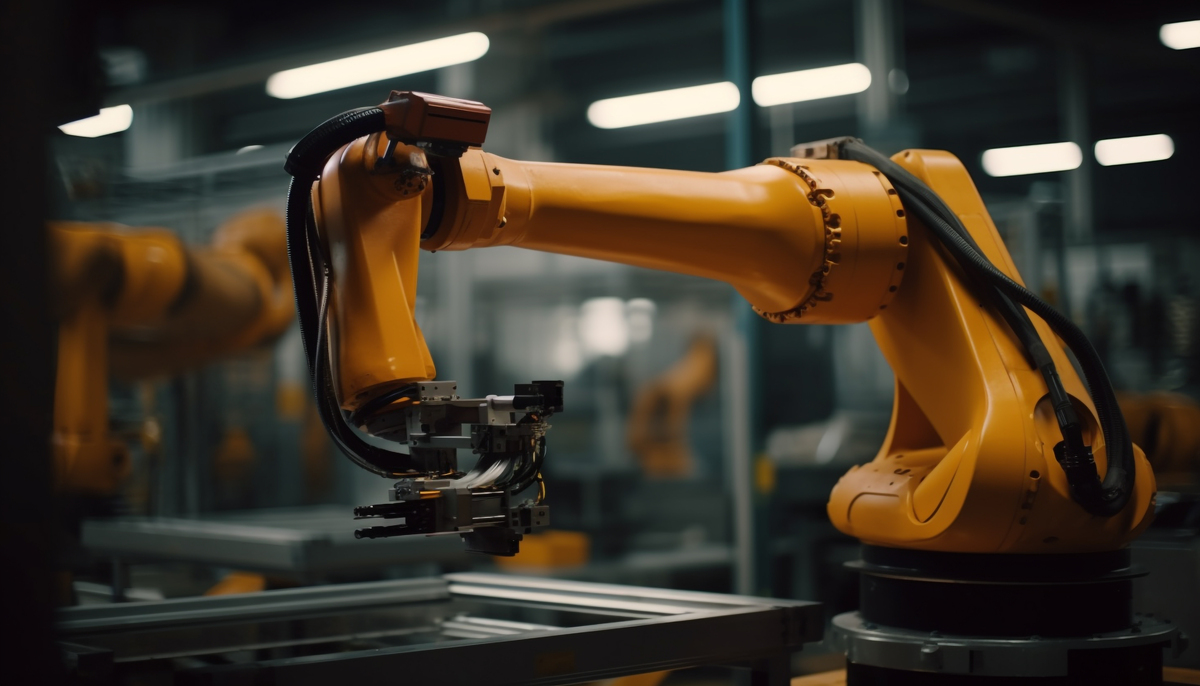

Automation and Robotics

Robotic systems and other automation technologies have completely changed many elements of warehouse operations. Robotic systems are capable of carrying out activities including material handling, sorting, and in some circumstances, even construction assembly. These robots have sensors, cameras, and cutting-edge algorithms that help them efficiently move around the warehouse and interact with the materials within.

Smart warehouse in construction frequently employ automated guided vehicles (AGVs) to move heavy equipment and supplies throughout the building. These AGVs run on their own, taking planned paths or responding to immediate inputs. As a result of eliminating physically taxing activities from human workers, there is a decrease in manual labor, an increase in efficiency, and a safety improvement.

Advanced Analytics and Predictive Maintenance

Advanced analytics are used by smart warehouse in construction to make wise judgments based on current data. Data analytics is used by the construction industry to improve inventory allocation, optimize warehouse layouts, and locate supply chain bottlenecks. Another use of analytics is predictive maintenance, where machine learning algorithms forecast when equipment will need maintenance, minimizing downtime and boosting operational effectiveness.

Construction warehouses can predict the need for maintenance on machineries like forklifts, conveyor systems, and AGVs by looking at past data. This proactive approach decreases maintenance costs, maintains uninterrupted warehouse operations, and reduces unexpected breakdowns.

Benefits of Smart Warehouse in Construction

In the construction sector, smart warehouse in construction have emerged as a game-changing technology that has transformed conventional warehouse management techniques. These warehouses provide a wealth of advantages that support increased project efficiency, cost savings, and better overall construction operations by merging cutting-edge technologies and data-driven methodologies.

1. Enhanced Inventory Management: Internet of Things (IoT) sensors and Radio Frequency Identification (RFID) are two technologies that smart warehouse in construction use to provide real-time visibility over inventory levels, locations, and movement. Due to their ability to expedite material handling, lower stockouts, and improve the procurement process, construction businesses can improve project workflows and decrease downtime.

2. Improved Operational Efficiency: In smart warehouse in construction, automation is crucial because it enables the automation of repetitive processes like picking, packing, and sorting. This lessens human error, quickens procedures, and makes it possible to significantly boost throughput. Construction projects can thus adhere to stricter deadlines and complete tasks on time.

3. Data-Driven Decision-Making: A lot of data about inventory, the supply chain, and operations is produced by smart warehouse in construction. This data can be processed by sophisticated analytics tools to yield insightful information that supports strategic decision-making. By identifying patterns, maximizing resource allocation, and foreseeing possible bottlenecks, these insights support the construction industry.

4. Enhanced Safety: Construction is a field where safety is of utmost importance, and smart warehouse in construction help to raise the bar. Smart devices and IoT sensors can monitor ambient conditions, spot potential dangers, and instantly alert the appropriate individuals. This proactive strategy reduces accidents and promotes a safer workplace.

5. Cost Savings: Although the upfront costs of adopting smart warehouse technologies may seem high, they are outweighed by long-term cost savings. Over time, a large return on investment is produced through lower operational expenses brought on by more effective resource use, inventory management that is streamlined, and decreased downtime.

6. Real-Time Tracking: Construction managers and project teams may be sure that they have correct information on the state of their resources thanks to the real-time tracking of materials and equipment provided by smart warehouse in construction. This avoids delays brought on by lost objects and aids in efficient resource allocation.

7. Client Satisfaction: The advantages of intelligent warehouses go beyond the site of construction. Clients gain from shorter project deadlines, fewer mistakes, and better results. Enhancing reputation and expanding business opportunities are influenced by meeting or exceeding client expectations.

8. Sustainability: Energy-efficient methods and procedures are frequently used in smart warehouse in construction, which helps achieve sustainability objectives. Environmentally responsible techniques are becoming increasingly important in the construction sector, and they are aligned with reduced energy usage, improved transportation routes, and low waste production.

Challenges and Considerations

There are numerous advantages to integrating smart warehouse technology into the construction sector, but there are also some problems and factors to take into account that must be carefully considered to ensure successful implementation. Construction companies must overcome these obstacles if they are to fully benefit from a smart warehouse environment as they work to improve operational efficiency and optimize their supply chain.

1. Initial Implementation Costs: The initial expenditure needed to use smart warehouse technologies is one of the main obstacles. IoT sensors, RFID systems, automation tools, and software solutions can come at a significant expense to buy and install. Despite the long-term cost reductions that these technologies promise, construction businesses should carefully evaluate their financial standing and create a clear cost-benefit analysis before taking on such projects.

2. Data Security and Privacy: Data gathering and analysis play a major role in smart warehouse in construction. Privacy and data security are raised by this. Strong cybersecurity measures are needed to prevent breaches and unauthorized access due to the influx of sensitive data, which includes everything from inventory information to staff actions. To safeguard their confidential information as well as the personal information of their employees, businesses must implement encryption protocols, access controls, and data anonymization procedures.

3. Workforce Transition and Training: The present staff may need to be retrained or upgraded as a result of automation and IoT devices. Employees must receive training to manage and interact with these technologies efficiently in order to reduce interruptions during the transitional period. Building a thorough training program guarantees the seamless integration of smart warehouse systems and reduces employee resistance to change.

4. Integration Complexity: Many old systems used by the construction industry need to be seamlessly integrated with new smart technology. This level of integration can be difficult and time-consuming to achieve. Effective software architecture, careful planning, and sometimes even specialized development approaches are needed to ensure compatibility between disparate systems and technologies.

5. Regulatory Compliance: Different regulatory regulations and compliance standards apply to the building business. To avoid legal ramifications, integrating smart warehouse in construction must adhere to these criteria. To maintain compliance and take advantage of technology improvements, it is essential to navigate the complicated environment of industry-specific rules and standards.

Case Studies: Successful Implementation Stories

The construction industry’s successful deployment of smart warehouse in construction in the real world offers important insights into the innovations’ revolutionary potential. These case studies highlight the beneficial effects that implementing smart warehouse solutions may have on a project’s overall success, cost savings, and efficiency.

1. XYZ Construction: Streamlining Inventory Management

A major participant in the construction sector, XYZ Construction, set out on a mission to optimize its warehouse operations through the incorporation of IoT and RFID technologies. They made real-time tracking and inventory management possible by adding RFID tags to construction supplies and machinery. This made it possible for the business to properly track material utilization, cut down on waste, and improve project planning in general. Due to exact delivery deadlines, XYZ Construction saw a significant decrease in project delays and an increase in client satisfaction by using smart warehouse in construction.

2. ABC Builders: Enhancing Safety Through Automation

The potential of automation in increasing safety procedures in their construction warehouses was identified by ABC Builders. To reduce the risk of accidents brought on by manual handling, they introduced autonomous cars to move big goods. They also put in place sensor-based systems to keep an eye on environmental factors like temperature and humidity to ensure the preservation of delicate goods. This innovative technique not only increased worker safety but also helped with regulatory compliance and downtime reduction.

These case studies show how flexible and expandable smart warehouse in construction are and how they may be used in a variety of construction projects. They show that making such investments is not only financially wise, but also in line with the industry’s rising emphasis on efficiency, safety, and sustainability.

The accomplishments of ABC Builders and XYZ Construction provide motivation for other construction firms to investigate and apply smart warehousing technology. Businesses can gain a competitive edge and improve project execution and customer happiness by utilizing the promise of IoT, automation, and data analytics.

Future Trends in Smart Warehousing for Construction

Smart warehouse in construction is one of the key areas that is experiencing transition as the building industry is on the cusp of a technological revolution. Modern technologies are enabling smart warehousing, which is set to revolutionize the way construction supplies and equipment are stored, tracked, and controlled. The landscape of smart warehousing in construction is anticipated to be shaped by a number of important changes in the next years.

1. Artificial Intelligence and Predictive Analytics

Predictive maintenance powered by AI is about to transform the smart warehouse in construction technology. AI can foresee the need for equipment maintenance, minimizing expensive breakdowns and assuring peak performance. This is done by analyzing data from sensors and IoT devices. This pattern reduces downtime while also extending the useful life of assets.

2. 5G Connectivity

The launch of 5G networks promises communication that is incredibly quick and has low latency. This increase in connectivity makes it possible to remotely monitor warehouse operations and transmit real-time data, which speeds up decision-making and increases efficiency overall.

3. Robotics and Automation

Automation and robots will increasingly be integrated. Moving materials around smart warehouse in construction can be handled by autonomous mobile robots, which will cut down on manual labor and streamline procedures. Alongside human labor, these robots can increase production while upholding safety regulations.

4. Advanced Data Analytics

Advanced analytics tools will be essential as data gains more and more value. With the use of these tools, construction organizations may optimize inventory levels, identify patterns, and make wise decisions for more seamless project execution.

5. Sustainability and Green Warehousing

The idea of “green warehousing” will catch on as environmental concerns rise. To build sustainable warehouses that adhere to their environmental commitments, construction companies will employ energy-efficient techniques, renewable energy sources, and eco-friendly materials.

These trends are already beginning to transform the building sector. Companies may drastically increase the productivity of smart warehouse in construction, cut operating expenses, and shorten project timeframes by adopting these innovations. Construction companies must keep up with these developments and take proactive measures to fully realize the benefits of smart warehousing.

Guidelines for Implementing a Smart Warehouse

Supply chain management in the construction sector can be revolutionized, and overall project efficiency can be increased, by implementing a smart warehouse in construction. But moving to a smart warehouse successfully necessitates rigorous employee training, strategic implementation, and careful planning. Here are crucial recommendations to take into account while putting in place a smart warehouse system in construction:

Assessment and Planning: Conduct a thorough evaluation of your current warehouse operations, infrastructure, and technology requirements before starting the implementation journey. Determine the problems, obstacles, and areas that can be improved. Make a clear plan that specifies the project’s scope, important checkpoints, and the desired results.

Technology Selection: Select technologies that fit the specific requirements and objectives of your warehouse. IoT sensors, RFID tracking, automated guided vehicles (AGVs), and inventory management software are typical technology for smart warehouse in construction. Make sure the technology you choose has scalability for future development and can interact easily with your current systems.

Vendor Evaluation: Research the reputation, record, and customer testimonials of potential technology vendors. Talk to many providers to learn about their services, customization options, and post-implementation assistance. References from other building firms that have successfully adopted comparable systems can offer insightful information.

Pilot Testing: Conduct a pilot test of the chosen technologies in a controlled environment before full-scale installation. In a risk-free environment, this enables you to spot any possible problems, improve the system, and train your team. Based on the comments and outcomes from the pilot phase, adjustments, and changes can be made.

Change Management and Training: Achieving staff buy-in is essential for a successful deployment. Inform your staff of the advantages of the smart warehouse in construction and resolve any questions or concerns. To ensure that personnel are able to use the new technology successfully and efficiently, offer thorough training sessions.

Data Security and Privacy: In a smart warehouse in construction, critical data protection is essential. Put in place reliable cybersecurity safeguards to prevent data breaches and unauthorized access. Make sure you are adhering to the local data protection laws.

Integration and Scalability: Create a smart warehousing system that can be integrated with other software and tools for managing construction projects. This integration improves overall project visibility and streamlines data transmission. Plan for future scaling as the project’s requirements and the technological environment change.

Continuous Monitoring and Improvement: After implementation, frequently check the system’s effectiveness and collect user feedback. To adapt the system to shifting needs and technological breakthroughs, identify opportunities for improvement.

Construction companies can effectively traverse the challenges of adopting a smart warehouse in construction by adhering to these recommendations. The change can result in more efficient project management, downtime reduction, inventory management, and streamlined operations.

Conclusion

The integration of smart warehouse in construction has become a revolutionary force in the constantly changing construction industry. The transition from conventional warehouses to intelligent, data-driven hubs has completely changed how supply chains are managed and projects are completed. As we approach the end of this investigation into using smart warehouse in construction, it is clear that embracing innovation is now more important than ever.

Adopting smart technology has numerous and significant advantages, as this guide emphasizes. These developments promise to expedite operations and improve project results, from real-time inventory tracking to simplified procedures and predictive maintenance. However, a thorough strategy is necessary for their successful integration.

Construction companies can plow a route to effective adoption by following the provided principles toward smart warehouse in construction. The foundation of this shift is made up of careful planning, technology selection, personnel training, and regular monitoring. It entails a cultural transition that involves adjusting to new working methods and making use of data insights, not just a change in infrastructure.

The change in the construction industry through smart warehousing will undoubtedly quicken as we move to the future. Automation, 5G connectivity, and AI-driven predictive analytics have the potential to significantly alter the landscape of the sector. The future construction warehouse is more than just a stockpile of supplies; it is a hub of innovation where construction knowledge and technology intersect to form a seamless, effective ecosystem.

Construction organizations will improve their competitiveness and contribute to a more sustainable, agile, and effective construction ecosystem by embracing this journey toward smart warehouse in construction. The journey ahead is fascinating, and those who grab the chance to incorporate intelligence into their warehouses will surely set the standard for how construction logistics will develop in the future.

Suggested article for reading:

Top 10 Green Building Materials

The Top 7 Green Architecture Projects

Resources:

Mckinsey & Company | Deloitte | Start US | Medium | Cyzerg | New Castel Systems | Tranquil

For all the pictures: Freepik