Exclusive Neuroject Article: The world is about to enter Industry 5 in construction, which will be another revolutionary period in industrial progress. The rise of Industry 5 in construction promises to change production, automation, and the very nature of employment itself as societies continue to struggle with the repercussions of the previous industrial revolutions.

Industry 4.0 lay the groundwork for the next stage of technological development, Industry 5 in construction, which will usher in a new era of innovation and disruption. In order to shed light on Industry 5’s potential to transform industries, economies, and society as a whole, this article examines its key traits, technologies, and ramifications.

Industry 5 in construction aims to boost economic growth by enabling new company models, increasing productivity, efficiency, and customization. However, it also presents difficulties, such as the necessity to upskill the workers to adapt to the shifting environment and the loss of jobs.

Table of Contents

Introduction

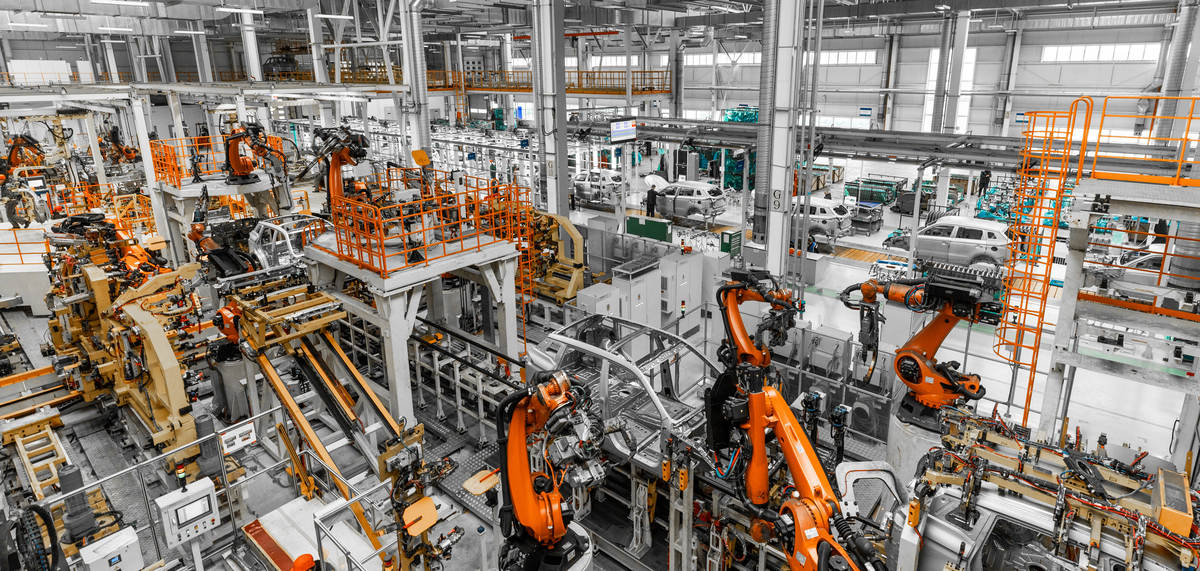

Imagine a world in which production processes are expertly coordinated with no need for human involvement, where robots interact effortlessly, and where factories are not simply automated but sentient. This is Industry 5’s promise as the next step in the development of manufacturing.

Emerging technologies are transforming how we create, produce, and consume, and Industry 5 in construction marks a paradigm shift that goes beyond the bounds of earlier industrial revolutions. Industry 5 in construction is ready to revolutionize industries and reinvent the foundation of our society.

From the revolutionary power of artificial intelligence (AI) to the endless potential of sophisticated robots and the Internet of Things (IoT), Industry 5 in construction is set to change everything.

In this article, we will delve into the intricacies of Industry 5 in construction and explore its implications across various domains. We will examine the core technologies that underpin Industry 5 in construction, including advanced robotics, AI, IoT, and additive manufacturing, and elucidate how these innovations are transforming traditional manufacturing processes.

It leverages new technology to provide prosperity beyond jobs and growth while respecting the planet’s production constraints and places the welfare of the worker at the center of the production process. By expressly placing research and innovation at the service of the transition to a sustainable, human-centered, and resilient European industry, it enhances the current “Industry 4.0” strategy.

Suggested article’s for reading:

What is IoT in Construction? Definition, Applications and Steps (2024)

Artificial Intelligence or AI in Construction Industry; Guide to 2024

Background and Evolution of Industrial Revolutions

The way people manufacture things is also altered by technological advancements. The industrial revolution is another name for the transition from pre-industrial technology to production technology. What exactly were the industrial revolutions, and where are we now? The phrase “From the First Industrial Revolution to Industry 4.0”

Industry 1.0: Through the use of steam power and the mechanization of industry, the First Industrial Revolution got its start in the 18th century. The mechanized version obtained eight times the volume at the same time as the basic spinning wheels that were previously used to create threads.

Industry 2.0: The invention of electricity and the introduction of the assembly line marked the start of the Second Industrial Revolution in the 19th century. Previously, an entire automobile was put together at one station; now, vehicles are made in small batches on a conveyor belt, which is much faster and less expensive.

Industry 3.0: Using computers and memory-programmable controls, the Third Industrial Revolution of the 20th century started in the 1970s. Since the development of these technologies, we have gained the ability to completely automate a production process without the use of humans.

Industry 4.0: The Fourth Industrial Revolution is being put into practice right now. It expands on the Third Industrial Revolution’s advancements. A network link allows production systems with computer technology to be expanded and, in a sense, have a digital twin online

Industry 4.0, in short, is revolutionary for all industrial settings. The production process will alter as a result of the digitalization of manufacturing, including how things are produced, delivered, and maintained. Because of this, it can legitimately claim to mark the start of the fourth industrial revolution.

What are Industry 5 in Construction Strategies?

There are 3 approaches in Industry 5 in construction; Human-Centric, Adaptive Strategy, and Sustainable Strategy.

Human-Centric Approach:

According to the infographic, a human-centric strategy “promotes talents, diversity, and empowerment.” It fits in well with recent changes in the labor market. Finding, serving, and retaining talent has become a considerably bigger task than finding, serving, and retaining customers in many businesses and nations.

Today’s strategy is mostly focused on acquiring a competitive edge and utilizing it to produce distinctive additional value for clients.

Adaptive Strategy:

A robust strategy is, in the words of the European Commission, “agile and resilient with flexible and adaptable technologies.” Few would disagree that resilience is essential—today and in the future—in light of Covid-19, global supply constraints, and the Ukraine conflict.

However, this transformation is more profound than it first appears. While flexibility and agility are currently higher on the corporate agenda, this does not automatically translate into greater resilience.

Sustainable Strategy:

With the many concerns we currently have over climate change, the concept of sustainability hardly needs an introduction. A sustainable strategy, in the words of the European Commission, “leads action on sustainability and respects planetary boundaries.” This suggests, for instance, that organizations should focus on all 17 Sustainable Development Goals and the three Ps of the Triple Bottom Line.

The third pillar is also a major change, just like the first two. Corporate sustainability initiatives have thus far mostly been concentrated on mitigating harm or engaging in greenwashing, but let’s leave that out of the conversation. So, it’s business as usual but with more responsibility.

Suggested article’s for reading:

Discovering the World’s Top 21 Sustainable Buildings

Top 7 Sustainable Architecture Projects

Industry 5 in Construction: The Future of Manufacturing

Industry 5 in construction refers to the coexistence of intelligent robots and humans, with increased resilience and sustainability objectives. Industry 5 in construction aims to bring back human, environmental, and social factors into the equation, whereas Industry 4.0 concentrates on technologies like the Internet of Things and big data.

In this sense, Industry 5 in construction can be seen as enhancing the accomplishments of Industry 4.0 in order to support rather than replace humans. Incorporating critical thinking and adaptation while moving away from excessive automation, preserves the precision and repeatability of machines while allowing people to step in when necessary.

Enhanced customization, increased production, and improved efficiency are a few of Industry 5’s main benefits.

- Increased Productivity

- Enhanced Efficiency

- Enhanced customization

Industry 5 in construction also has the ability to promote innovation, lower prices, boost safety, and enable environmentally friendly manufacturing methods.

Industry 5 in construction poses issues and problems that must be resolved even though it promises revolutionary breakthroughs. Job displacement and the need to upskill the workforce are two main areas of concern.

- Job displacement may result from automation, growing AI use, and robotics in Industry 5 in construction, especially for tasks that are simple to automate.

- To operate and maintain cutting-edge technologies, Industry 5 in construction needs a workforce with new skill sets.

It is essential to make investments in thorough education and training programs that concentrate on fostering expertise in fields like data analysis, AI programming, robotics, and cybersecurity in order to address these difficulties.

Key Technologies Driving Industry 5 in Construction

A variety of cutting-edge technologies are altering the way we create items, provide services, and run enterprises in today’s industry. We shall examine some of the major technological trends influencing the direction of Industry 5 in construction in this post.

Artificial intelligence (AI): AI is at the forefront of technical advancement in business. AI gives computers the ability to carry out activities like perception, reasoning, learning, and decision-making that otherwise need human intelligence.

Robotics: Another important technology advancing the industry is robotics. Modern robots are used in a variety of industrial contexts to automate activities, increase accuracy, and boost productivity.

Internet of Things (IoT): The industrial landscape has changed dramatically as a result of the Internet of Things. IoT links machines, sensors, and gadgets to allow for intelligent decision-making and real-time data transmission.

Additive Manufacturing: The production of items is changing thanks to additive manufacturing, often known as 3D printing. Using this technique, intricate items can be built up layer by layer from digital drawings.

Big Data Analytics: The ubiquity of digital technologies has caused an exponential rise in the production of data. Large and complex datasets are processed and analyzed as part of big data analytics in order to find patterns, trends, and insights.

These crucial technologies are propelling industry transformation and opening up new opportunities. But problems like cybersecurity concerns, moral issues, and the necessity to upskill the workforce come with their adoption. To fully fulfill these technologies’ promises, companies must address these issues and adapt them appropriately.

Suggested article for reading: Construction Robots in 2024

Implications of Industry 5 on Society and the Economy

The impact of Industry 5 in construction, which is fueled by cutting-edge technologies like automation, artificial intelligence (AI), robotics, and the Internet of Things (IoT), on society and the economy is substantial. While it has many advantages, it also brings difficulties and calls for varied levels of adaptation.

The possibility for employment displacement is one of Industry 5’s major effects on society. Some occupational roles may disappear as a result of automation, artificial intelligence (AI), and robotics, especially those that are simple to automate. This gives rise to worries about unemployment and the requirement for impacted workers to retrain or find alternative employment possibilities.

On the other side, Industry 5 in construction also offers chances to create new jobs. There is a growing need for knowledgeable experts in fields like AI programming, data analysis, robotics, and cybersecurity as new technologies are developed.

Industry 5 in construction also has implications for the economy. It has the potential to drive economic growth and competitiveness. Increased productivity, improved efficiency, and enhanced customization offered by Industry 5 in construction can lead to higher output, reduced costs, and improved customer satisfaction.

The growing usage of AI and robotics in Industry 5 in construction also raises ethical issues. It is necessary to address concerns like data privacy, algorithmic bias, and the effect on human workers. In order to ensure the responsible and ethical use of new technologies, society must adopt rules and laws that strike a balance between possible benefits and issues of justice, transparency, and responsibility.

Conclusion

The idea of Industry 5 in construction has not yet acquired much popularity. Even early versions of Industry 4.0 are still being actively used by businesses. Additionally, the sustainability train has only recently started to move significantly. But the fact that the EU encourages businesses to advance and bases its Industry 5 in construction framework on these three pillars gives businesses an idea of what real advancement will entail in the coming years.

The attraction or difficulty of this vision will vary widely between businesses and individuals. Additionally, there will be a significant difference in how widely it will be accepted. But considering the significant problems and crises we are currently facing, it is clear that Industry 5 in construction is a viable and desired solution. We can anticipate the emergence of solutions once organizations—and as a result, societies—become more human-centric, resilient, and sustainable.

The effects of Industry 5 in construction on society and the economy are significant. The issues associated with job displacement, worker upskilling, closing the digital divide, and assuring ethical and responsible deployment must all be addressed even as it brings innovations that improve productivity, efficiency, and personalization. Society may use Industry 5’s revolutionary capacity for the benefit of people, companies, and the economy as a whole by proactively addressing these implications.

Suggested article for reading:

The Top 7 Green Architecture Projects

important construction technology in 2024

7 Important Building Technology Ideas for 2024

Resources:

European Commisssion | Desoutter Tools | forbes

Journal articles:

- Lasi, H., Fettke, P., Kemper, H.-G., Feld, T., & Hoffmann, M. (2014). Industry 4.0. Business & Information Systems Engineering, 6(4), 239-242.

- Gaurav, K., Bhushan, B., & Kumar, A. (2019). Industry 5.0: A human-centric approach for future industrialization. Robotics and Computer-Integrated Manufacturing, 58, 1-13.

- Kumar, S., Dwivedi, Y. K., & Kumari, A. (2020). Industry 5.0: A new paradigm for modern manufacturing business. Journal of Manufacturing Technology Management, 31(8), 1611-1642.

- Porter, M. E., & Heppelmann, J. E. (2014). How smart, connected products are transforming competition. Harvard Business Review, 92(11), 64-88.

- Brynjolfsson, E., & McAfee, A. (2014). The second machine Age: Work, progress, and Prosperity in a time of brilliant technologies. W. W. Norton & Company.

- Schwab, K. (2017). The Fourth Industrial Revolution. Crown Business.

- Muro, M., & Maxim, R. (2017). Automation and Artificial Intelligence: How machines are affecting people and places. Brookings Institution.

- Vrontis, D., Christofi, M., & Thrassou, A. (2020). Industry 5.0: Upgrading to smart and sustainable manufacturing for global competitive advantage. Technological Forecasting and Social Change, 155, 120049.

- Manyika, J., Chui, M., & Miremadi, M. (2016). Where machines could replace humans—and where they can’t (yet). McKinsey Quarterly.

- World Economic Forum. (2020). The Future of Jobs Report 2020.

- Wang, L., & Kusiak, A. (2019). Industry 4.0: A comprehensive survey. Computers in Industry, 109, 184-201.

- Grieves, M. (2014). The convergence of Big Data and the Internet of Things. In Enabling Things to Talk (pp. 7-16). Springer.

- Berman, B. (2012). 3-D printing: The new industrial revolution. Business Horizons, 55(2), 155-162.

For all the pictures: Freepik