Technology is gradually replacing construction and altering how a project is completed. It is anticipated that a large portion of work will be done automatically shortly, greatly reducing the necessity for physical labor. Construction robots can be of considerable assistance for tasks that call for accuracy and speed. Furthermore, they have no trouble overcoming obstacles on the site related to physical exhaustion or limitations in human power. Construction robotics are emerging to tackle some of the most dangerous, labor-intensive, and repetitive activities and give workers a safer, more controlled environment as automation becomes more and more crucial for the future of construction.

However, several obstacles still need to be addressed before robots can be successfully and widely deployed on construction sites. These include the dynamic nature of the worksite, the high initial cost of robot acquisition, the requirement for new worker training, the modification of conventional workflows, and the general reluctance of construction companies to test these new technologies in their projects. Similarly, before off-site production can expand much further, a few significant obstacles including size constraints and logistics still need to be resolved.

One of the labor-intensive industries has long been thought to be the building sector. However, there are just not enough skilled individuals to match the industry’s demands these days. Professionals in the construction sector have witnessed a good deal of change over the years. However, this one is distinct. Amidst the bricks and beams, construction robotics may seem like a strange land. Construction robotics, however, are already improving and streamlining procedures on the job site. Building and a lot of other businesses are experiencing interesting times right now.

Table of Contents

Construction Robotics Explained

Engineering that combines computer science, mechanical, and electrical engineering is called robotics. It’s now at last making its way into the construction sector, bringing with it some innovative and exciting new options.

It has long been acknowledged that the construction industry is among the most labor-intensive and physically taxing. But things are improving because of automation and robotics. Construction robotics are coming to expedite work, minimize human mistakes, and prevent fatigue-related setbacks.

Consider large machinery used in construction, such as trucks and bulldozers. We can give them a cognitive boost using robotics. They are swift and accurate in jobs like digging, lifting, hauling, and concrete and demolition work.

Successful construction robotics require a strong complementarity between human presence and robot functions. Locating the ideal gathering spot might be difficult. To improve efficiency, we need to combine the best attributes from each side. To the extent possible, a thorough classification of the various advantages and disadvantages of each party can greatly aid in the pursuit of harmonious human-robot collaboration.

In this instance, the key concept is that while robots may do jobs requiring remarkable strength and speed, construction people should concentrate on those where their presence is required.

The human ability to handle small-scale projects requiring careful handling can be the ideal complement to robots’ capacity to do larger jobs in impressively shorter amounts of time. Therefore, it makes sense that robots may significantly alter the construction industry. Of course, though, they have benefits as well as drawbacks.

Suggested article to read: The Role of Climbing and Inspection Robots in Construction Safety; 2024 Guide

How Robotics is Changing the Construction Industry

Automation is the driving force behind the rapid changes in the globe. It is well established that computers and robots can complete a variety of activities more quickly, safely, and affordably than people. Though the construction robotics business isn’t particularly well-known, there are currently several robots available that are intended to assist construction workers.

Anticipating a surge of innovation in construction robotics, the next ten years hold great promise. This has the potential to fundamentally change not just the building industry but also the architecture and engineering fields. The main concern for you and almost everyone else, though, is undoubtedly “Are these robots going to replace hardworking humans?” It’s not an easy response.

The goal of technology is to improve and simplify human labor, not to replace it. Consider safety, which is crucial in the construction industry. We can eliminate the risk associated with some tasks for people when robots take over. Construction robotics have not come to replace humans, even though they can perform certain specialized jobs. Human interaction is still necessary in a field like building.

The nature of work will inevitably alter as robotic technology is incorporated into the construction industry more and more. Humans and robots each have unique advantages. Though in different ways, they are both necessary.

Robots will be better at performing longer, more labor-intensive jobs, while construction people will continue to tackle the more creative and complex aspects of projects. In the end, the building company may make a sizable profit from this partnership. Therefore, even though the future is not known, robotics will certainly have an impact and alter the way we do building.

Benefits of Construction Robotics

To begin with, there are many advantages to deploying construction robotics. These machines indeed have the potential to significantly alter the sector. Here are a few of their principal benefits:

Suggested article to read: The Role of 3D Printing Robots in Construction; 2024 Guide

1. Fewer Errors Made on Site

The reduction of errors is one of the key benefits of deploying construction robotics. Because robots can ensure accuracy, they can prevent human error from occurring throughout the construction process. This holds for the work being done on the job site as well as for the process’s scheduling and planning. Reductions in errors will mean fewer delays and repair tasks. Each of these components has the potential to positively affect the project’s overall budget.

2. Reduced Construction Process Costs

Construction robotics, as we have already indicated, can significantly lower the entire cost of the building process. Lowering the amount of time needed to complete a task and minimizing project delays together can help control costs. In the long run, this may result in more inexpensive housing options.

3. Protecting the Labor Force

For construction workers, integrating construction robotics into the process can offer two major advantages. It first makes sure they continue to be in better shape for a longer period. Now that the heavy manual labor can be handled by robots, humans may remain on-site to oversee the entire project. Furthermore, since some of the riskiest operations on site will be carried out automatically and more accurately, worker safety will also be enhanced.

4. Improving the Industry’s Profile

The construction sector struggles to raise its profile. There’s a prevalent perception that it’s a tedious and slow field. If robotic machinery is used in the building process, this might drastically alter.

All of a sudden, young people who aspire to pursue ambitious careers related to emerging technology will find building enticing. The influx of youthful, intelligent individuals into the sector will offer significant answers to the labor scarcity that the construction industry is presently facing.

5. Better-quality Constructions

Construction robotics are capable of carrying out jobs more precisely and quickly than humans. In the end, this may result in more durable building constructions that blend in seamlessly with their environment. Put another way, shortly, robots will be able to provide longer-term building solutions. They may also encourage the development of novel architectural forms, such as green buildings.

6. Achieving Deadlines

Construction managers can plan their projects more efficiently because of automation in the process. Improving the process’s overall accuracy will enable all agents involved in the building to meet deadlines and save expenditures of time and money.

Suggested article to read: What are Demolition Robots in Construction? 2024 Guide

Disadvantages of Construction Robotics

Although integrating construction robotics offers many advantages, there are some disadvantages as well. Among the drawbacks that are most important to note are the following:

1. Fewer Construction-related Jobs

Construction robotics will create new and interesting opportunities for those with a passion for technology, but they will also reduce the number of jobs that need to be done on-site. While it can’t completely replace human presence, robotic machinery can limit it to a considerable degree.

2. The Price of Purchasing the Robotic Devices

Construction robotics can help your budget during the construction management process, as we have previously seen. However, purchasing the machinery still comes at a very expensive cost. As such, there’s a good risk that the greatest technology will be concentrated in the hands of a smaller number of corporations that can afford to buy it. Because of this, a lot of small and medium-sized construction firms might eventually close their doors.

3. Employee Education

Purchasing the appropriate equipment is one thing. But it’s different when you have someone who knows how to handle it. Businesses will need to invest a significant amount of time and resources to teach staff members how to use this state-of-the-art equipment. However, considering the influence construction robotics can have on the administration of a building project, this is something that should be considered a long-term investment.

Types of Construction Robotics

There are other kinds of construction robotics besides the one that most people associate with the image of a bipedal, metal-framed automobile. Many different types of machines help in construction, ranging from driverless cars to real human workers.

Suggested article to read: Bricklaying Robots in Construction Automation; 2024 Guide

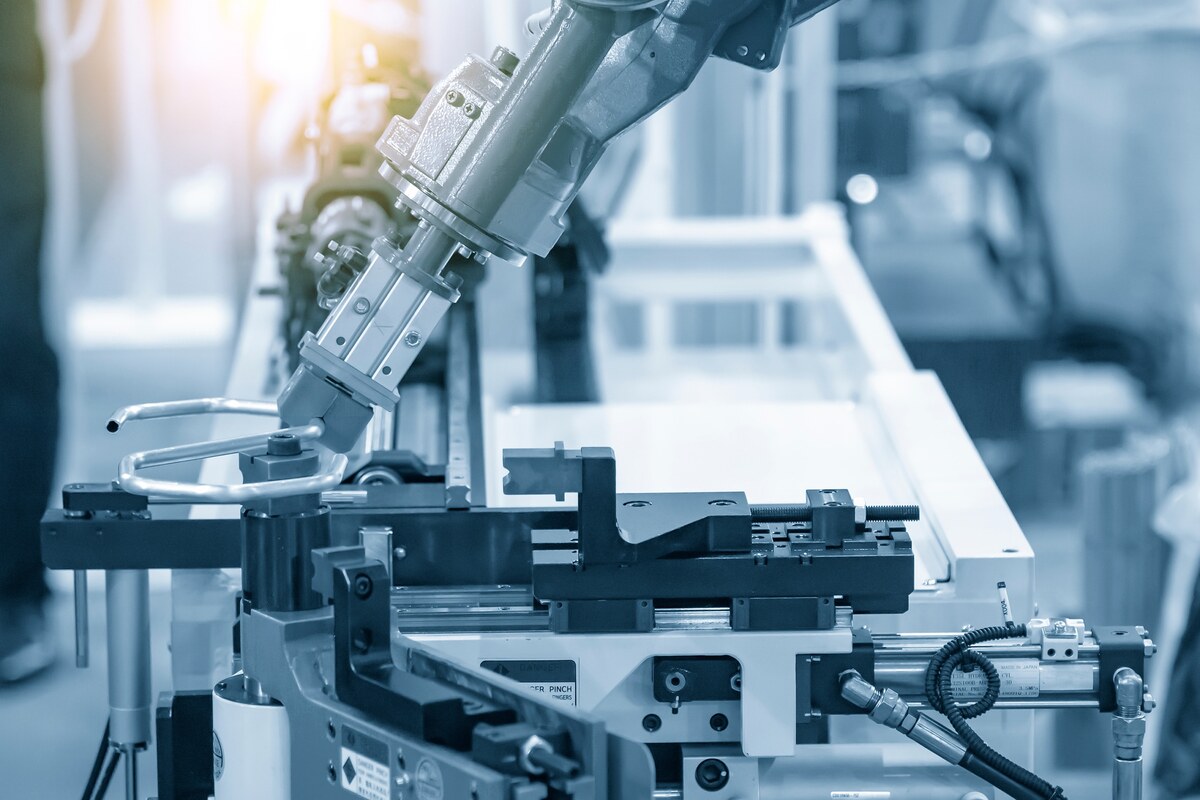

1. Industrial Robots

The most well-known automation is the industrial robots used in manufacturing. As construction technology develops, construction robotics is being used more frequently in the sector to carry out high-value, repetitive jobs. There are three typical uses for industrial robots:

Manufacturing with Articulated Robots: Manufacturing robots are referred to as articulated robots. They are employed for many different purposes and bear a striking resemblance to a human arm. An articulated robot can be used for anything from basic assembly to welding. Armored robots are already being employed for space construction because of their extreme versatility. One construction robotic crane attachment on the ISS and LunarGateway that helps minimize human intervention is the Canadarm.

3D Printing Using Cartesian Robots: A cartesian robot is a robot that uses the three-axis system (X, Y, and Z) of cartesian coordinates. It is sometimes referred to as a linear robot or gantry robot. These robots are widely used for many different activities, such as loading and pick-and-carry, but 3-D printing is one application where their popularity has skyrocketed.

One of the most widely used technologies to join the building sector is 3-D printing. This is because a range of things, such as a home that is 3-D printed, can be produced. The ability to 3-D print a house quickly, effectively, and affordably could render traditional home construction obsolete.

Humans Working Together With Collaborative Robots: Cobots, another name for collaborative robots, are construction robotics made to cooperate with humans to complete activities that would be too challenging for each one of them to complete on their own. In the construction business, a persistent lack of workers is a regrettable trend. However, cobots have the potential to alleviate this pressure and eventually take the place of human laborers for low-skilled tasks.

2. Drones

Drones have become more and more popular in the construction industry, and this makes sense. Their adaptability on building sites contributes to project progress and safety. These robots are special because they can deliver real-time updates on a construction project and are remotely controlled with airborne capabilities, which revolutionizes the project life cycle and eliminates the need for human labor.

The application of drones in construction will only develop as long as the sector expands and innovation keeps rising. Among the positions they have enhanced are:

Using Drones for 3-D Mapping: Drone mapping is one method of doing this; a drone takes a thorough aerial picture of the job site, which can then be converted into a three-dimensional model. This enables contractors to identify possible obstacles during the design phase and make plans for them. In the long term, this can result in cost savings by providing a more realistic budget forecast.

Remotely Observing and Examining Workplaces: Drones can perform vital inspections without the trouble of hiring a boom lift or big cranes that need multiple operators. Due to its ability to fly, a drone can investigate structures that are difficult to access.

Maintaining Security: One of the most crucial elements of a building site is security. The construction industry loses between $300 million and $1 billion annually due to theft, of which less than 25% is recovered. Although there are limits to what humans can accomplish, security may be readily increased by using drones. Drones can be operated by a single person to get an aerial image of the entire scene.

Suggested article to read: Top 7 Robotic Welding and Fabrication Types in Construction (2024)

3. Self-Driving Construction Vehicles

While the auto industry is actively working on standardizing autonomous vehicles—such as Tesla’s Autopilot feature—the construction sector has been employing autonomous construction equipment for some time.

A startup called Built Robotics is “Upgrading off-the-shelf heavy equipment with AI guidance systems” at the moment. At the moment, the business offers fully autonomous dozers, excavators, and CTLs in its lineup. The primary problem this can resolve is road construction safety.

Even the best road construction safety plan can’t always protect workers from human error, and working on a street with traffic can be perilous for construction workers. However, human error can be significantly reduced by using autonomous construction trucks.

Upgrading Construction Jobs with the ATL: The Autonomous Track Loader (ATL) from Built Robotics is a small track loader that can operate without an operator thanks to its augmented GPS and LiDAR (light detection and ranging) sensors. Excavation for family dwellings is one of the light construction tasks for which this autonomous vehicle is intended.

Doing More with Dozers: Dozers are multipurpose equipment that may be used for everything from leveling various types of soil to pushing large things. All of that can be accomplished by the autonomous dozer from construction robotics without the need for a human driver.

Maintaining Work Performance Using Excavators: The autonomous excavator from Built Robotics is capable of doing trenching, truck loading, and foundation excavation tasks just like any other excavator. When an operator is on standby, it performs admirably. On the other hand, the excavator’s autonomous feature lets less skilled users do far more. To teach its members how to drive these new autonomous cars, Built Robotics and the International Union of Operating Engineers (IUOE) are collaborating.

Another factor contributing to the popularity of autonomous vehicles is safety. Even though becoming a heavy equipment operator requires significant training, incidents involving operators of construction equipment still occur. Human error is almost eliminated when self-driving construction robotics is used.

4. Humanoid Laborers

The construction sector is presently experiencing a manpower shortage. Even though employment is available, the industry’s apparent lack of interest is getting noticed. And so the humanoid laborer arrives—a fully autonomous robot with human-like features. These workers shouldn’t be mistaken for other androids, such as Star Trek’s Chief Operations Officer Data, but the construction robotics that follows bring that reality much closer.

Fighting Humans with HRP-5P: The HRP-5P is the closest humanoid construction robotics that comes to mind when people imagine robots capable of executing human-like tasks. The HRP-5P is a humanoid robot that was created by Japan’s Advanced Industrial Science and Technology. It can carry out a range of duties by combining object identification and environment sensing technologies.

The HRP-5P is still in the prototype stage, but it can already operate power tools and hang drywall sheets by itself. However, despite the HRP-5P’s continued existence, human labor is still required.

Colonizing Space with NASA’s Valkyrie: The process of constructing and expanding out in space is known as “Space construction,” and while that part is already becoming a reality, there are still many challenging steps to be taken, such as establishing upshop on Mars. This is where NASA’s R5 comes in. It is designed to be a “Robust, rugged, entirely electric humanoid robot capable of operating in degraded or damaged human-engineered environments.” This robot is also referred to as the Valkyrie.

Like its namesake, the Valkyrie is essentially built to be hardy and resilient, leading people to a new and exciting place. Sending a few of these humanoid laborers to work on Mars, where the colony is still in the pre-development stage, might be exactly what we need to advance as a multi-planetary race.

Top 5 Construction Robotics Companies

Technology has completely changed the way that construction is done, increasing efficiency, and productivity, and producing more sustainable results. Much of this progress can be attributed to robotics. Construction companies that manufacture and supply construction robotics equipment and related services have become major actors in the industry’s transformation.

1. Construction Robotics

Construction robotics is a prominent player in the construction robots sector, offering its SAM100 masonry automation machine, which essentially does the work of six expert masons. The machine’s efficacy has resulted in a 50% decrease in labor expenses and doubled construction speed. Additionally, it offers MULE, which may be mounted to a robot and used in dangerous areas. It can lift objects to 135 kg.

2. Boston Dynamics

One of Boston Dynamics’ most well-known products is the Atlas robot, which can execute a variety of jobs like opening doors and climbing stairs. It is intended to help with building projects, namely with BIM modeling and demolition.

3. Fastbrick Robotics

Bricklaying procedures can be automated with the help of cutting-edge technology from Fastbrick Robotics. The company has an amazing bricklaying construction robotics that can place up to 1,000 bricks in an hour—that’s three masons’ worth of work. This implies that a brick wall that would take days to construct by hand can now be completed in a matter of hours.

4. Hadrian X

Bricklaying robot Hadrian X from FBR is affixed to a vehicle and is capable of bricklaying on-site. It can guarantee the immediate life of building structures up to a maximum height of 3.6 meters. The goal of this automation is to reduce construction costs as much as possible without sacrificing safety standards.

5. EksoWorks

Industrial exoskeletons are created by EksoWorks to give workers doing physical labor—like lifting or drilling—more support. With the use of this technology, employees can minimize physical strain while maintaining a full range of motion, which reduces the risk of injury increases productivity, and lowers worker compensation.

Conclusion

While it’s unlikely that construction robotics will ever fully replace human labor in the construction sector, there are plenty of ways they may be utilized to speed up, improve safety, simplify, and reduce labor-intensive tasks on the job site.

The most likely scenario is that human workers will employ robots to supplement their labor, increase productivity, and keep them safer. Given the current capabilities of robots and the developing labor scarcity, robots will likely take over some of the more routine and menial activities, freeing up human workers to concentrate on other elements of their jobs.

The main goal of technological advancement is progress. But the focus should be on making the job better rather than on upgrading and replacing the current workers. Construction robotics are made to help and adjust to the dynamic world we live in today. Improvements in construction technology are generally utilized to boost safety, which is one of the most critical parts of any task on any job site. Therefore, it’s not as simple as answering “Yes” or “No” to the question of whether robots will eventually replace humans.

Indeed, robots can perform tasks that humans cannot, such as building underwater. However, since construction is one of the riskiest sectors, robots are being used to assist with work and increase safety.

Let’s just say that robots won’t be replacing humans anytime soon. Drones and cobots are only two examples of the various robotics that still require human interaction. A person would still need to be present on the scene even if they were able to create an autonomous trencher. Indeed, robots are on the horizon, but they’re on our side.

Suggested article for reading:

What is Robotic Material Handling? 2024 Guide

Robotic Excavators and Diggers in Construction Automation; 2024 Guide

Resources:

ConstructionDigital | FBR | BigRentz | StandardBots | ZacuaVentures | LetsBuild | ConstructConnect | BlueBeam | Autodesk

For all the pictures: Freepik