The timing is now right for construction automation to play a significant part in assisting in the full blossoming of construction’s digital transformation, even though research and implementation of these technologies have progressed more slowly in the industry than in manufacturing.

Automation will be essential to the construction industry’s future development in various ways, from automated digital design and analysis procedures to automated construction documentation creation and, eventually, automated construction itself. Whether it is applied to on-site construction robotics or off-site prefabrication in construction that emulates the best practices of advanced manufacturing, automation of construction processes will determine the construction industry’s success in meeting its dual challenges of the twenty-first century: the high demand for buildings and infrastructure and the requirement of sustainability throughout the entire lifecycle.

Similar opportunities and problems that automated manufacturing processes have helped resolve in other industries could also be addressed by construction automation. These problems include those related to labor shortages, environmental impact reduction, new design opportunities, worker health and safety, production time, material efficiencies, labor productivity, and so forth.

Table of Contents

What is Construction Automation?

Construction automation includes the use of automated processes, tools, and equipment in building and infrastructure progress. It consists of cloud-based models for data exchange, off-site and on-site automation, and software-based design.

Real-time sensing, industrialized building—which integrates manufacturing techniques into construction processes—and collaborative robotics are three major technologies propelling construction automation. By removing old processes and immediately integrating digital models into production lines, automation improves productivity, safety, and quality. The goal of human-machine cooperation is still to balance the effects on the environment, worker safety, and return on investment.

Suggested article to read: The Role of Digital Transformation in Sustainable Future; 2024 Review | Digital Transformation Management; 2024 Guide

Types of Construction Automation

Construction automation involves employing automated construction workflows, tools, and equipment to construct structures. Here are some examples:

1. Off-Site Construction Automation

- Overview: By moving procedures to factories, it imitates modern production.

- Technologies: Makes use of DfMA techniques, prefabrication, and industrial robotics.

- Benefits: Lowers waste, maximizes resources, and boosts safety.

2. On-Site Construction Automation

- Difficulties: Equipment needs to be flexible and portable for work locations.

- Examples: Contains concrete reinforcement automation and layout robots.

3. Robotics in Construction

- Role: On building sites, robotics—particularly collaborative robots—improve accuracy and productivity.

- Examples: Bricklaying robots like SAM100 and site-scanning robots like NeXtera’s Oliver.

4. Autonomous Construction Equipment

- Overview: Autonomous machinery and cars increase efficiency and safety.

- Examples: Consists of autonomous dozers and trenching systems for renewable energy projects.

12 Cutting-Edge Technologies in Construction Automation

Construction automation is revolutionizing the sector through increased productivity, lower expenses, and better project results. Modern building projects are increasingly using construction automation as smart technologies gain traction.

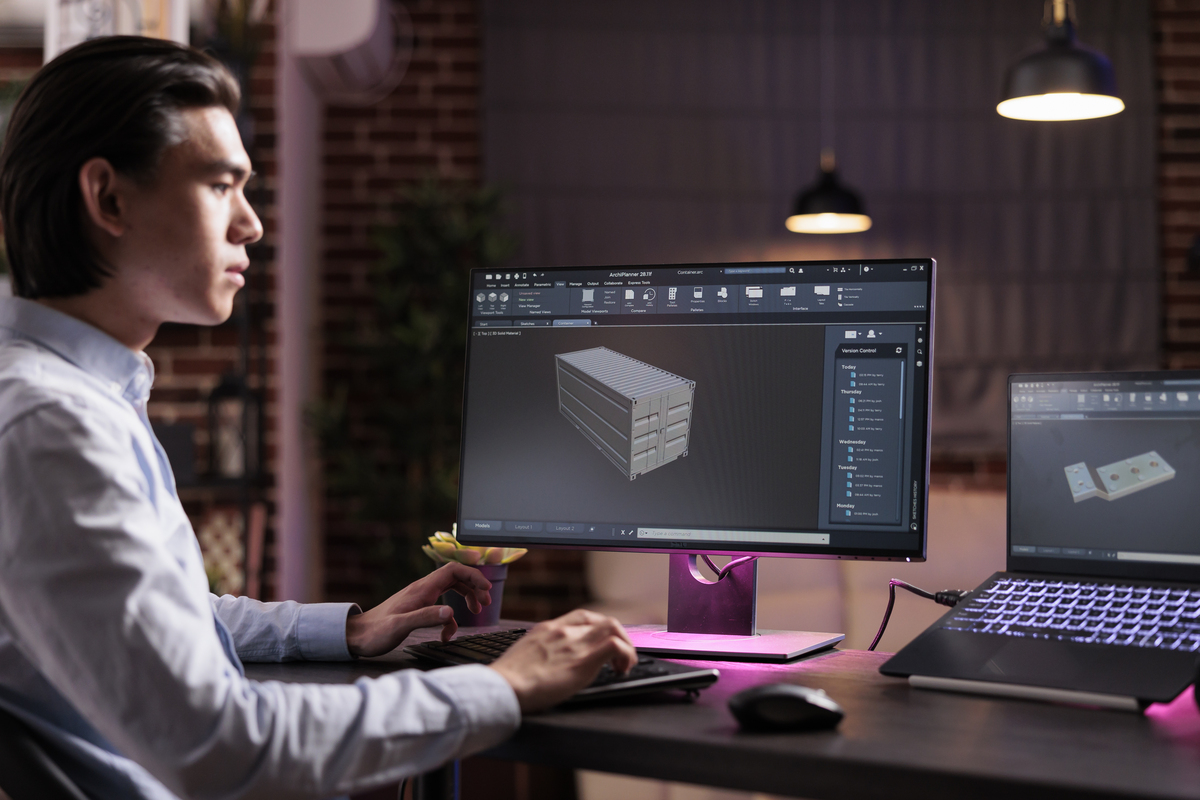

1. BIM, or Building Information Modeling

Building Information Modeling (BIM) is a digital depiction of a structure’s structural and operational features. By giving stakeholders a common model for simulation, visualization, and decision-making, it enhances stakeholder collaboration. Over the course of a project, BIM improves coordination, accuracy, and efficiency.

2. AI-Powered Robotics

Robots using artificial intelligence (AI) are revolutionizing construction jobs including welding, concrete pouring, and bricklaying. These robots carry out activities with extreme accuracy and efficiency by using AI and machine learning techniques. Their versatility for a range of construction purposes stems from their ability to adapt to varied conditions and tasks.

Suggested article to read: Top 7 Robotic Welding and Fabrication Types in Construction (2024) | What are Demolition Robots in Construction? 2024 Guide

3. 3D Printing

Using a variety of materials, 3D printing robots in construction automation entails layer by layer creation of building components. With the use of this technology, complex geometries may be produced quickly and with little waste, improving sustainability and speeding up construction. Additionally, it provides scalability and adaptability for different tasks.

4. Drones

Drones in construction are widely utilized for progress tracking, site surveying, and inspection. Drones with high-definition cameras and building sensors enable accurate planning and monitoring by providing real-time aerial images of construction sites. By lowering the requirement for manual inspections in dangerous regions, they improve safety solutions.

5. Modular Construction and Prefabrication

Building components are prefabricated and assembled on-site after being constructed off-site. Because modular construction minimizes waste and cuts down on on-site construction time, it can result in faster and more affordable building procedures.

6. AR, or Augmented Reality

Augmented Reality (AR) superimposes digital data on the real world, facilitating decision-making and visualization. By offering construction automation and real-time data and visuals, augmented reality in construction can help with design verification, project planning, and on-site problem solving in the construction industry.

7. Wearable Technology

Exoskeletons and smart helmets are examples of wearable technology in construction that improve efficiency and safety. Exoskeletons lessen physical strain by supporting the worker’s movements, while smart helmets offer real-time data on ambient factors and worker health.

8. Autonomous Machinery

Cranes and other autonomous machines, including bulldozers, work on their own thanks to AI and sensors. By precisely completing dangerous and repetitive jobs, these devices can lower human error and increase efficiency and safety on construction sites.

9. The Internet of Things

Construction automation by IoT devices improve equipment management and predictive maintenance by gathering and transmitting data from construction sites. They make it possible to monitor environmental factors and machinery in real time, which enhances operational safety and efficiency.

10. Cloud-Based Construction Management Software

Project management is made easier by construction automation and cloud-based solutions, which include analytics, real-time data access, and collaboration capabilities. These systems improve stakeholder communication and expedite project operations.

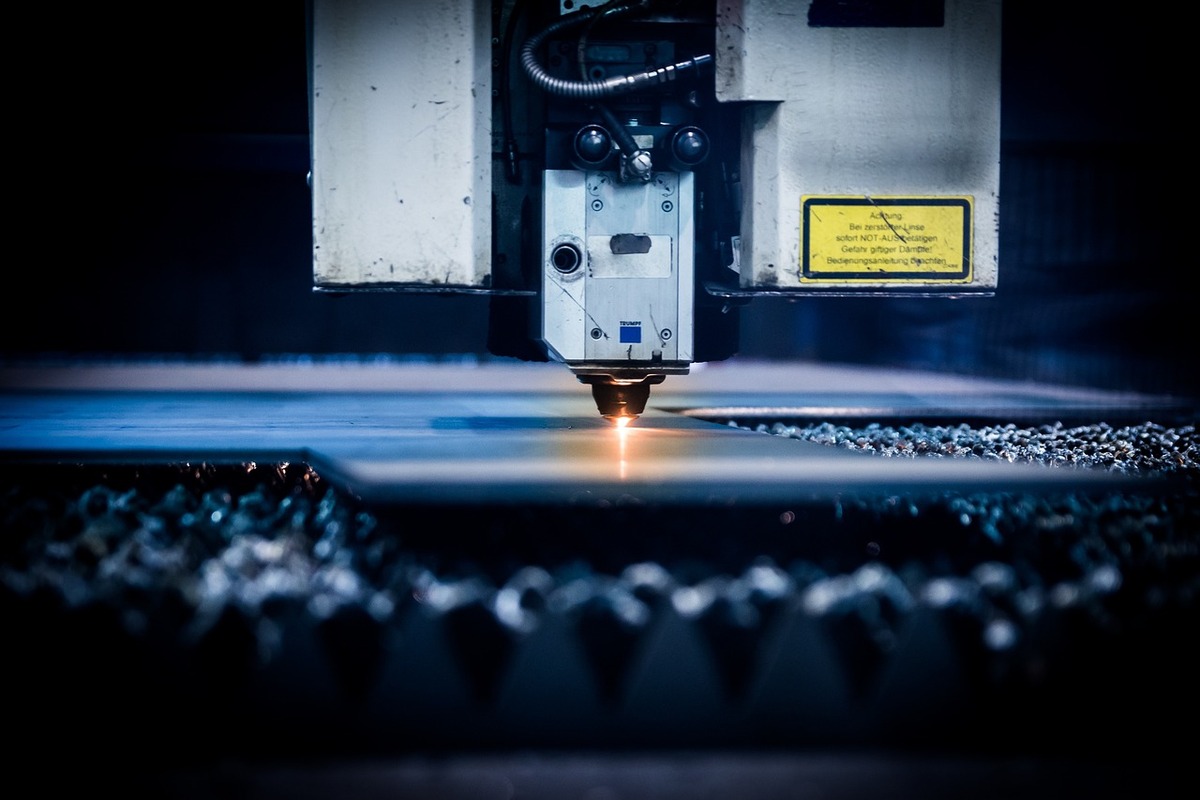

11. Laser Scanning in Construction

Sites and constructions can be measured in three dimensions in detail using laser scanning. This technology provides extremely accurate spatial data, which helps with quality control, design verification, and as-built documentation.

12. Digital Twins

Digital twins are digital copies of physical assets that enable predictive maintenance and real-time monitoring. They provide proactive management and operational efficiency by offering insightful information about the functionality and state of structures.

Benefits and Challenges of Various Aspects of Construction Automation

| Aspect | Benefits | Challenges |

| Efficiency |

|

|

| Quality |

|

|

| Productivity |

|

|

| Sustainability |

|

|

| Labor |

|

|

| Project Management |

|

|

| Flexibility |

|

|

Conclusion

Construction automation is rapidly changing the industry by focusing on several major obstacles concurrently. The amalgamation of sophisticated robots, artificial intelligence-driven apparatus, and inventive manufacturing methodologies not only addresses the persistent shortage of labor but also amplifies overall effectiveness and output.

Automation makes it possible to complete complicated activities more accurately and consistently, which lowers the risk of human error and increases safety on building sites. Furthermore, by reducing waste and improving resource use, this technological revolution makes a significant contribution to environmental sustainability.

The construction industry can now satisfy the growing needs for eco-friendly building methods and affordable housing by automating traditional operations. This aligns with modern expectations for innovation and accountability. This progress not only guarantees the industry’s flexibility and competitiveness in a world that is changing quickly, but it also creates a future in which building methods are more in line with efficient and sustainable development objectives.

FAQs

What is Construction Automation, and how is it Transforming the Industry?

- Answer: Building projects are improved by the use of automated tools and equipment in construction automation. By using digital models and striking a balance between environmental and worker safety issues, it increases production, safety, and quality.

How does Building Information Modeling (BIM) Benefit Construction Projects?

- Answer: With the use of a digital model of a structure provided by BIM, stakeholders may collaborate more effectively and efficiently, which improves project outcomes.

How do AI-powered Robotics Improve Construction Tasks?

- Answer: Robots driven by AI can execute jobs like bricklaying and welding with great accuracy and adaptability, increasing output and decreasing mistakes.

Automation in Construction: A Guide to 2024

Building Automation System (BAS): Ultimate Guide for 2024

AI for Construction Vehicle Automation: Neural Networks and Machine Learning Approaches

Resources:

AutoDesk | BuiltWorlds | McKinsey | ScienceDirect.com | LibGen

Books and Articles:

What Is Construction Automation, and How Will It Drive the Future of Building? (Mark Davis)

Bock, T., & Linner, T. (2015). Construction Robotics. Springer.

Eastman, C., Teicholz, P., Sacks, R., & Liston, K. (2018). BIM Handbook: A Guide to Building Information Modeling for Owners, Designers, Engineers, and Contractors. Wiley.

Wu, P., Zhang, Z., & Zhao, X. (2016). “3D Printing Technology and Its Applications in Construction Industry.” Journal of Cleaner Production.

J. K. Liu, W. Y. K. Wong, & M. W. H. Leung. (2018). “The Applications of Drones in Construction Industry.” Journal of Automation in Construction.

A. K. Aslam & S. J. Lee. (2021). “The Role of IoT in Construction: A Review of IoT Applications and Challenges.” Automation in Construction.

For all the pictures: Freepik | Pixabay