Safety is a cornerstone of the construction industry, where every project presents a myriad of challenges and risks. From towering skyscrapers to intricate infrastructure, construction sites are dynamic environments where the well-being of workers and the public must be paramount. In this context, the integration of robotic solutions emerges as a transformative force, revolutionizing traditional approaches to safety and efficiency.

This guide delves into the pivotal role of robotic solutions in construction safety, focusing on climbing and inspection robots, and their profound impact on vertical operations. As we embark on this exploration, it is imperative to recognize the multifaceted importance of safety in construction.

First and foremost, the preservation of human lives stands as the foremost imperative. Construction sites are inherently hazardous, with the potential for accidents and injuries lurking at every turn. Whether working at great heights, navigating confined spaces, or operating heavy machinery, construction workers face a multitude of risks that necessitate diligent safety measures.

Moreover, adherence to safety regulations and standards is not merely a legal obligation but a moral imperative. Governments worldwide enforce stringent guidelines to safeguard the well-being of construction workers and the public, with non-compliance carrying severe penalties and consequences for construction companies.

Furthermore, the significance of safety extends beyond regulatory compliance to encompass broader considerations such as reputation, productivity, and cost-effectiveness. Companies that prioritize safety foster a positive reputation within the industry, attracting clients and talent while mitigating risks associated with accidents or lapses in safety protocols.

In light of these considerations, the emergence of robotic solutions heralds a new era in construction safety. Climbing robots offer unparalleled access to vertical structures, minimizing the need for workers to undertake perilous tasks at height. Inspection robots, equipped with advanced sensors and imaging technology, provide accurate assessments of structures while reducing human exposure to hazardous environments.

As we navigate through the following chapters, we will delve deeper into the transformative potential of climbing and inspection robots, exploring their capabilities, benefits, and implementation considerations. Through this exploration, we aim to shed light on how robotic solutions are reshaping the landscape of construction safety, paving the way for safer, more efficient, and sustainable practices in the industry.

Table of Contents

Importance of Safety in Construction Provided by Climbing and Inspection Robots

The importance of safety in construction cannot be overstated, as the industry is inherently hazardous due to the nature of the work involved. Here are several key points highlighting the significance of safety in construction:

- Human Lives: Construction sites are prone to accidents, which can result in injuries or fatalities. Ensuring safety measures are in place helps protect the lives of workers, visitors, and nearby residents.

- Legal Compliance: Governments around the world enforce strict regulations and standards to ensure the safety of construction workers and the public. Non-compliance can lead to severe penalties, fines, and legal consequences for construction companies.

- Reputation and Brand Image: Companies that prioritize safety build a positive reputation within the industry and among clients. Conversely, accidents or safety lapses can damage a company’s brand image, leading to loss of contracts and business opportunities.

- Productivity and Efficiency: Safe working environments promote higher productivity and efficiency among workers. When employees feel secure and protected, they can focus better on their tasks, leading to improved performance and project outcomes.

- Cost Savings: Implementing safety measures upfront may require investment, but it ultimately leads to cost savings in the long run. Accidents and injuries result in medical expenses, legal fees, compensation claims, and project delays, all of which can significantly inflate project costs.

- Worker Morale and Retention: Workers are more likely to remain loyal to companies that prioritize their safety and well-being. A positive safety culture fosters employee morale, leading to higher job satisfaction, lower turnover rates, and increased loyalty.

- Public Relations: Construction projects often attract public attention, especially large-scale developments in urban areas. Demonstrating a commitment to safety not only protects workers but also reassures the public and local communities about the project’s impact on their surroundings.

- Project Continuity: Accidents and injuries can disrupt construction projects, leading to delays, rework, and additional expenses. By prioritizing safety, construction companies minimize the risk of interruptions and ensure the smooth continuity of operations.

Suggested article to read: How to Improve Construction Productivity? Guide to 2024

Safety is paramount in the construction industry, not only for ethical and moral reasons but also for legal compliance, business reputation, productivity, cost savings, and overall project success. By investing in safety measures and fostering a culture of safety, construction companies can protect their workers, enhance their reputation, and achieve better project outcomes.

Climbing Robots: Revolutionizing Vertical Operations

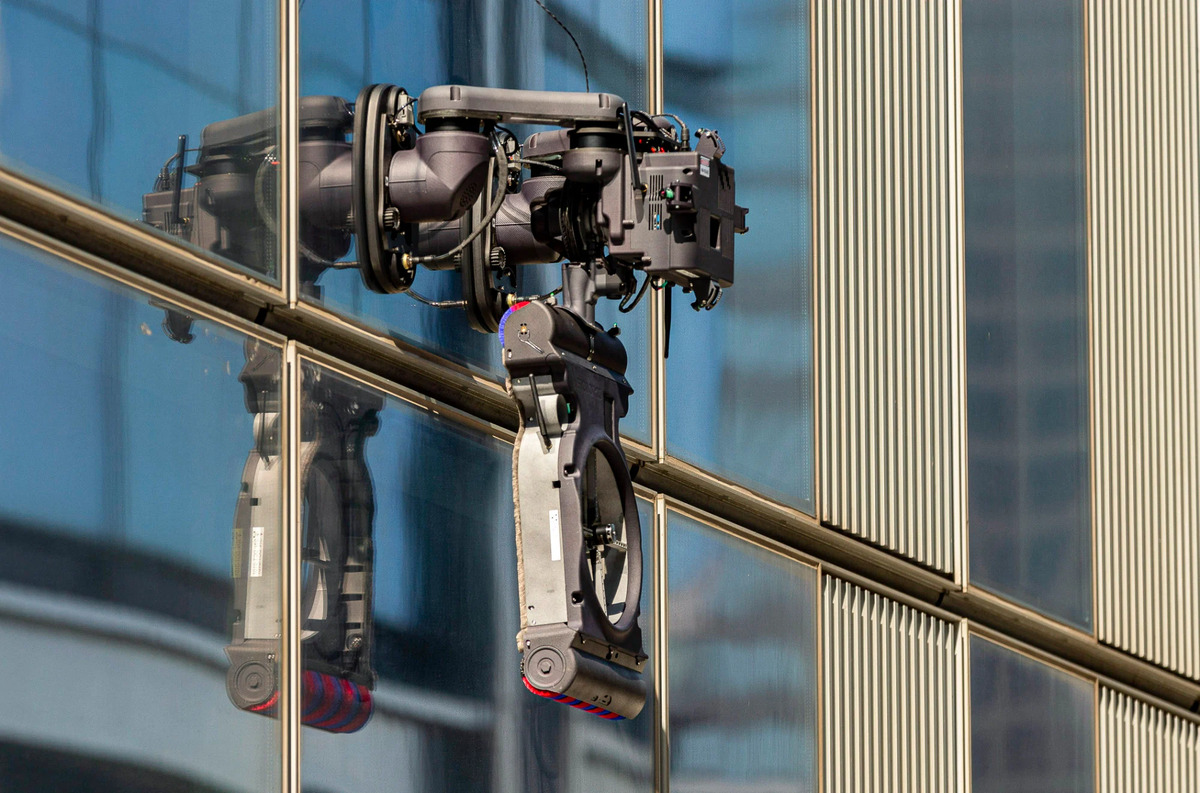

Climbing robots are revolutionizing vertical operations in the construction industry, offering innovative solutions to challenges associated with working at height. Here are several ways in which climbing robots are transforming vertical operations:

- Accessibility to Hard-to-Reach Areas: Climbing robots are designed to access vertical or inclined surfaces that are difficult or dangerous for humans to reach. This includes tall buildings, bridges, towers, and other structures where traditional methods of access, such as scaffolding or cranes, may be impractical or unsafe.

- Increased Safety for Workers: By utilizing climbing robots, construction companies can reduce the need for workers to perform tasks at height, thereby minimizing the risk of falls and other accidents. This enhances overall construction site safety and helps protect the well-being of workers.

- Efficiency and Productivity: Climbing robots can perform various tasks more efficiently than human workers, thanks to their precision, speed, and ability to work continuously without fatigue. They can carry out tasks such as painting, cleaning, inspection, and maintenance with greater accuracy and consistency, ultimately speeding up project timelines and reducing costs.

- Remote Operation and Monitoring: Many climbing robots are equipped with advanced technology that allows them to be controlled remotely, either from the ground or from a safe location nearby. This enables operators to perform tasks from a distance, minimizing their exposure to hazardous environments and improving overall operational efficiency.

- Versatility and Adaptability: Climbing robots come in a variety of designs and configurations to suit different applications and environments. They can be equipped with various tools, sensors, and equipment to perform a wide range of tasks, from surface cleaning and coating to structural inspection and repair.

- Environmental Benefits: By using climbing robots instead of traditional methods that require heavy machinery or scaffolding, construction companies can reduce their environmental footprint. Climbing robots are often more energy-efficient and produce fewer emissions, making them a more sustainable option for vertical operations.

- Cost-Effectiveness: While the initial investment in climbing robots may be significant, their long-term benefits in terms of safety, efficiency, and productivity can result in substantial cost savings for construction companies. By reducing the risk of accidents, minimizing downtime, and improving overall project performance, climbing robots offer a high return on investment over time.

Suggested article to read: Top 11 Construction Safety Tips for 2024

Climbing robots are revolutionizing vertical operations in the construction industry by offering safer, more efficient, and cost-effective solutions for working at height. As technology continues to advance, climbing robots are likely to play an increasingly important role in shaping the future of construction.

Inspection Robots: Enhancing Safety and Efficiency

Inspection robots are playing a crucial role in enhancing safety and efficiency in various industries, including construction. Here’s how they are making an impact:

- Remote Inspection Capabilities: Inspection robots can access confined or hazardous spaces that may be difficult or dangerous for humans to enter. Equipped with cameras, sensors, and other detection tools, these robots can remotely inspect structures, equipment, and infrastructure for defects, damage, or potential safety hazards without putting human inspectors at risk.

- Minimized Human Exposure to Hazards: By deploying inspection robots, construction companies can significantly reduce the need for workers to perform manual inspections in hazardous environments, such as tall buildings, bridges, tunnels, and industrial facilities. This helps minimize the risk of accidents, injuries, and exposure to harmful substances, improving overall safety on construction sites.

- Enhanced Data Collection and Analysis: Inspection robots are equipped with advanced sensors and imaging systems that can collect detailed data about the condition of structures and assets. This data is then analyzed using artificial intelligence (AI) and machine learning algorithms to identify defects, anomalies, or areas requiring maintenance or repair. By providing accurate and reliable information, inspection robots enable proactive maintenance planning, helping to prevent costly downtime and unplanned shutdowns.

- Increased Efficiency and Productivity: Inspection robots can conduct inspections more quickly and efficiently than human inspectors, thanks to their ability to navigate complex environments and perform repetitive tasks with precision and consistency. This results in faster inspection cycles, reduced labor costs, and improved overall productivity on construction projects.

- Real-Time Monitoring and Reporting: Inspection robots can provide real-time feedback and reporting on the condition of structures and assets, allowing construction companies to make informed decisions and take timely corrective actions as needed. This proactive approach to maintenance and asset management helps minimize the risk of costly repairs, downtime, or safety incidents.

- Improved Accuracy and Documentation: Inspection robots produce detailed and accurate documentation of inspection findings, including photographs, videos, and sensor data. This documentation serves as a valuable record of asset condition over time, facilitating compliance with regulatory requirements, insurance claims, and warranty obligations.

- Adaptability to Various Environments: Inspection robots come in a variety of designs and configurations to suit different inspection tasks and environments. Whether inspecting vertical structures, confined spaces, underwater infrastructure, or hazardous environments, there are inspection robots available to meet the specific needs of construction projects.

Suggested article to read: Construction Safety Sensors; Guide to 2024

Inspection robots are enhancing safety and efficiency in construction by minimizing human exposure to hazards, improving data collection and analysis, increasing productivity, providing real-time monitoring and reporting, ensuring accuracy and documentation, and adapting to various inspection environments. As technology continues to advance, inspection robots are expected to play an increasingly important role in optimizing construction processes and improving overall project outcomes.

Safety Benefits of Robotic Solutions

Robotic solutions offer numerous safety benefits across various industries, including construction. Here are some of the key safety advantages:

- Reduced Human Exposure to Hazards: Robotic solutions can perform tasks in hazardous environments, such as working at height, confined spaces, or areas with potential exposure to toxic substances, without putting human workers at risk. This minimizes the likelihood of accidents, injuries, and occupational health issues.

- Mitigation of High-Risk Activities: climbing and inspection robots can handle high-risk activities, such as heavy lifting, repetitive tasks, or working in extreme temperatures, with precision and consistency. By taking on these tasks, robots help reduce the physical strain on human workers and minimize the risk of musculoskeletal injuries and fatigue-related accidents.

- Enhanced Monitoring and Surveillance: Robotic systems equipped with sensors, cameras, and other monitoring devices can continuously assess the work environment for safety hazards, such as structural weaknesses, gas leaks, or potential sources of ignition. This real-time monitoring enables proactive risk management and timely intervention to prevent accidents or mitigate their consequences.

- Improved Ergonomics and Workstation Design: Collaborative robots (cobots) are designed to work alongside human workers in a shared workspace, assisting them with tasks that require precision, strength, or dexterity. By collaborating with robots, human workers can avoid awkward postures, repetitive motions, and other ergonomic risk factors that can lead to musculoskeletal disorders or workplace injuries.

- Accurate and Reliable Inspections: Inspection robots equipped with advanced sensors and imaging systems can conduct thorough inspections of structures, equipment, and facilities with greater accuracy and reliability than human inspectors. By identifying defects, anomalies, or safety hazards early on, inspection robots help prevent catastrophic failures, unplanned downtime, and safety incidents.

- Remote Operation and Telepresence: Teleoperated or remotely controlled robots allow operators to perform tasks from a safe location, away from hazardous environments or potentially dangerous situations. This remote operation capability reduces the need for human workers to physically enter hazardous areas, minimizing their exposure to risk while maintaining productivity and operational efficiency.

- Training and Simulation: Virtual reality (VR) and augmented reality (AR) technologies can be used to train workers in safety procedures, emergency protocols, and hazardous tasks in a simulated environment. By providing realistic training scenarios without exposing workers to actual risks, VR and AR simulations help improve safety awareness, preparedness, and response capabilities.

- Compliance with Regulations and Standards: Robotic solutions can help construction companies and other industries comply with regulatory requirements and safety standards by automating tasks by established guidelines. By adhering to safety regulations, companies can avoid penalties, fines, and legal liabilities associated with non-compliance.

Suggested article to read: Construction Monitoring Solutions: Your Complete Guide

Robotic solutions offer a wide range of safety benefits, including reduced human exposure to hazards, mitigation of high-risk activities, enhanced monitoring and surveillance, improved ergonomics and workstation design, accurate inspections, remote operation and telepresence, training and simulation, and compliance with regulations and standards. By incorporating robotics into their operations, companies can create safer work environments, protect the well-being of their employees, and enhance overall safety performance.

Implementation Considerations

When implementing robotic solutions, especially in industries like construction where safety is paramount, several key considerations should be taken into account:

- Safety Assessment: Conduct a thorough safety assessment of the work environment to identify potential hazards and risks that may impact the deployment and operation of robotic systems. Ensure that safety measures are in place to mitigate these risks and protect both human workers and robotic equipment.

- Risk Management: Develop a comprehensive risk management plan that outlines procedures for identifying, assessing, and controlling risks associated with robotic operations. Implement safeguards, such as emergency stop mechanisms, protective barriers, and interlocks, to prevent accidents and ensure safe interactions between humans and robots.

- Integration with Existing Processes: Evaluate how robotic solutions will integrate with existing workflows, equipment, and systems within the organization. Ensure compatibility and interoperability with other technologies and tools to optimize efficiency and minimize disruptions to operations.

- Training and Education: Provide training and education for employees on the safe use, operation, and maintenance of robotic systems. Ensure that workers understand how to interact with climbing and inspection robots safely and are aware of emergency procedures in the event of malfunctions or accidents.

- Operator Competency: Assess the competency and proficiency of operators responsible for controlling or supervising robotic operations. Ensure that operators have the necessary skills, knowledge, and experience to operate robotic systems effectively and safely.

- Maintenance and Support: Establish a maintenance schedule and procedures for inspecting, servicing, and repairing robotic equipment to ensure optimal performance and reliability. Provide access to technical support and troubleshooting resources to address any issues or concerns that may arise during operation.

- Data Security and Privacy: Implement measures to protect sensitive data and information generated by robotic systems, such as inspection reports, sensor data, and operational logs. Ensure compliance with data security regulations and protocols to safeguard against unauthorized access, misuse, or disclosure of confidential information.

- Scalability and Flexibility: Consider the scalability and flexibility of robotic solutions to accommodate changes in project requirements, workload demands, and business priorities. Choose modular, adaptable systems that can be easily reconfigured or upgraded to meet evolving needs and challenges.

- Cost-Benefit Analysis: Conduct a cost-benefit analysis to assess the financial implications of implementing robotic solutions, including upfront investment costs, operating expenses, and potential return on investment. Evaluate the long-term benefits, such as increased productivity, improved safety, and reduced downtime, to justify the investment in robotic technology.

- Stakeholder Engagement: Involve key stakeholders, including employees, management, suppliers, and regulatory authorities, in the implementation process to gain their input, support, and buy-in. Foster open communication and collaboration to address concerns, address feedback, and ensure successful adoption of robotic solutions.

Suggested article to read: Predictive Maintenance in Buildings | How To Reduce Construction Cost; 11 Tips

By carefully considering these implementation considerations, organizations can successfully deploy robotic solutions in a safe, efficient, and sustainable manner, leading to improved operational performance and enhanced safety outcomes.

Conclusion

In the realm of construction, safety isn’t just a moral obligation—it’s a strategic imperative. As outlined in this discussion, the significance of safety cannot be overstated, given the inherent hazards present in construction environments. From protecting human lives to ensuring legal compliance, safety considerations permeate every aspect of construction operations.

The implementation of robotic solutions further underscores the commitment to safety in construction. Climbing robots offer innovative alternatives to traditional access methods, reducing the risk of falls and accidents while enhancing productivity. Inspection robots provide accurate and reliable assessments of structures, minimizing human exposure to hazardous environments and facilitating proactive maintenance planning.

However, the successful integration of robotic solutions requires careful consideration of various factors. Safety assessments, risk management strategies, and operator competency are paramount to ensuring the safe deployment and operation of robotic systems. Moreover, addressing data security, scalability, and stakeholder engagement are essential elements of a comprehensive implementation plan.

Ultimately, investing in safety measures and embracing robotic solutions not only protects the well-being of construction workers but also enhances project outcomes. By fostering a culture of safety, construction companies can safeguard their reputation, minimize costs, and achieve greater efficiency and productivity.

As technology continues to advance, the construction industry has an opportunity to leverage climbing and inspection robots to further improve safety performance. By prioritizing safety at every stage of construction projects and embracing innovative technologies, we can create a future where construction sites are not only productive and efficient but also safe and secure for all involved.

Suggested article for reading:

Construction Cost Estimating; Ultimate Guide for 2024

5 Workers Monitoring Solutions in Construction Industry

Resources:

Science Direct | Research Gate | Sage Journals | Asimovo | MDPI | Hausbots

For all the pictures: Freepik | South China | Hausbots | Boston Dynamics | Weston Robots