A machine that builds and assembles structures can take the place of some manual labor in construction thanks to a relatively new technology called 3D printing in construction. This may be a more practical, economical, and ecologically friendly method of building new structures.

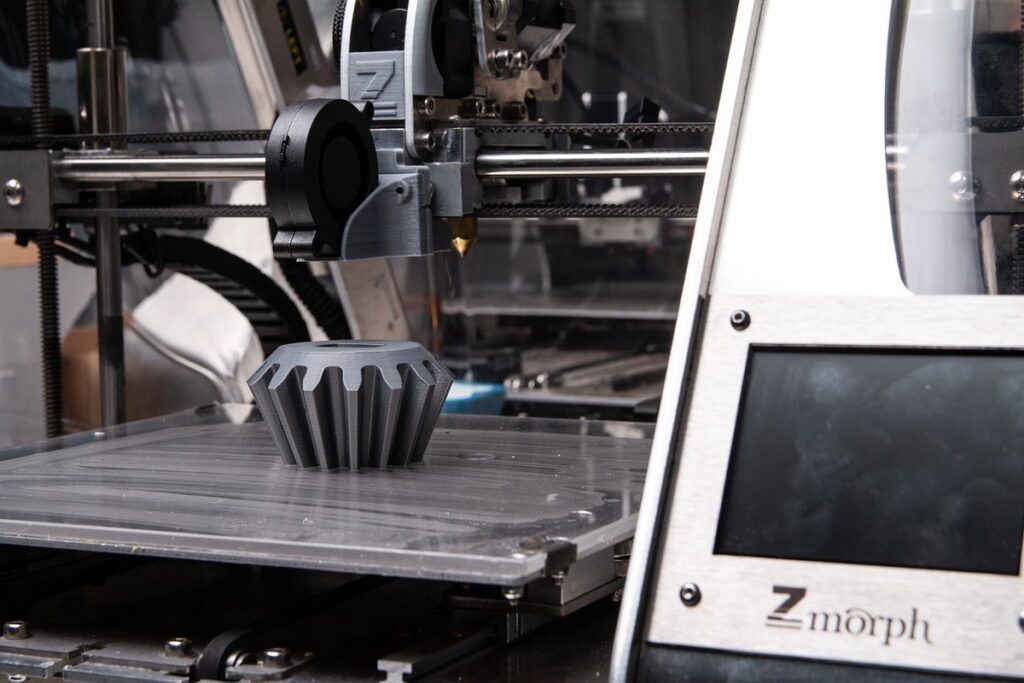

You may determine whether applications of 3D printing in construction might help you increase client happiness and optimize operations by learning about its advantages. With three-dimensional (3D) printing, virtual blueprints may be turned into tangible constructions. 3D printers use metal, plastic, or resin to build thin layers. They keep piling layers on top of each other until they have a finished edifice.

Computer-aided design (CAD) software is often used by 3D printing robots to obtain the information they need to direct their printing process. Products can be made with 3D printers. Larger buildings can also have their pieces or components printed by them. A 3D printer, for example, can produce particular parts for building projects.

Applications of 3D printing in construction are about to take off. According to Precedence Research’s projections, the construction industry will reach a value of $519.49 billion until 2032. The market’s valuation in 2022 was a mere $3.42 billion.

Table of Contents

What is 3D Printing in Construction?

Applications of 3D printing in construction is an innovative technology that involves the sequential layering of materials to create three-dimensional structures based on computer-generated models. This process, often referred to as additive manufacturing, allows for the precise and efficient creation of complex shapes that would be difficult or time-consuming to achieve using traditional construction methods.

The materials commonly used in 3D printing in construction include cement, plastics, and even liquid metals. These materials are deposited layer by layer, following the exact dimensions and specifications provided by software programs, resulting in highly accurate and durable structures. By leveraging this technology, construction projects can significantly reduce waste, minimize errors, and shorten production timelines, making 3D printing in construction an increasingly attractive option in the industry.

Types of 3D printing in construction

There are three major kinds of 3D printing in construction:

1. Robotic Arm Extruders

- This technique, known as contour crafting, uses a moving robotic arm or crane-like device to extrude material and create layers.

- Usually utilized in construction for smaller applications of 3D printing in construction.

- The building site is surrounded by rails that can be used to change the arm’s height and location.

- To prevent concrete from solidifying during printing, more manual labor, such as mixing and pouring, can be necessary.

2. Sand Layering

- To build buildings, the 3D printer applies layers of sand.

- Upon reaching the required thickness, the printer discharges droplets which solidify and consolidate the sand.

- Ideal for building materials or smaller-scale projects.

3. Combined with Different Technologies

- Welding and 3D printing in construction are compatible technologies.

- Raw materials can be layered by robotic arms or other printers, and while printing, welding solidifies the layers.

- Used to build intricate constructions without a conventional basis, such as bridges.

Suggested article to read: 11 Examples of 3D Printed Houses | Environmental Sustainability in Smart Construction Solution (2024)

Applications of 3D Printing in Construction

There are several construction situations where you can use 3D printing. Here are a few examples for applications of 3D printing in construction:

1. Robotic Arm Extrusion

One of the applications of 3D printing in construction are Gantries, which are big frames, are used for installation in 3D printers. This framework allows the printer to be moved up and down. In this configuration, the printer generates a 3D item by adding numerous 2D layers from the bottom up.

One printing setup that is more versatile is robotic arm extrusion. The printer nozzle is fixed to a revolving head of a mechanical arm. More flexibility is provided by this arrangement, which is essential for some building projects. For example, walls can be enhanced with items such as a printer fixed on a robotic arm.

Extrusions using robotic arms can also be helpful for huge components that are too big to fit on a gantry. In cement, these instruments are frequently utilized.

2. 3D Concrete Printing

Layer by layer, 3D printers construct things and architectural details. This is one of the applications of 3D printing in construction that can sometimes be used by a printer to build a whole house from the ground up. Before adding roofing, 3D printers are usually used to lay the foundation and apply layers of concrete for the walls. Recently, a Texas-based startup used concrete printing to build a small house.

3. Prototyping

A crucial component of pre-construction planning may be prototyping. When used in conjunction with building design and construction, 3D printing can expedite the prototyping process and enable the rapid creation of several prototypes.

There are various uses for these prototypes.

- An whole building’s scale prototype aids in determining the structure and viability of the project. In order to identify any possible trouble spots, engineers might examine or test the model.

- Additionally, a prototype can aid in ensuring precise measurements for the project’s schedule and cost estimations. Using a 3D model helps increase cost estimating accuracy.

- Prototypes of particular components can be created by engineers and designers for testing. Before making several components for their project, they can utilize it to iron out any kinks and refine the concept.

Construction project managers may occasionally be able to understand the CAD drawings for the 3D printed prototype using software. To help with project planning and the creation of more precise estimates, they can enter this data into construction planning software.

4. Additive Welding

Additives for welding One technique for producing metal parts for building is 3D printing. This procedure is referred to as wire arc additive manufacturing (WAAM) in technical terms. To construct a three-dimensional structure, the 3D printer constantly welds layers of metal.

This is one of the applications of 3D printing in construction that works particularly well for intricate or difficult welding tasks or metal building components. This method is ideal for building since it yields robust structural components.

5. Powder Binding

Powder binding is covering a surface with thin layers of powder and then misting it with a binding agent to form a solid. Metal, ceramics, sand, polymers, or mineral composites can all be used as binding materials.

A designer can construct intricate designs by using thin jets of binding liquid to form solids in specified areas. Building entire three-dimensional structures is made possible by repeating the binding process for every layer that comes after it.

Binding agents and powder are frequently less expensive than other 3D printing materials. Very tiny jets can also spray liquid and make intricate patterns. A vast variety of materials can be printed on with this technique.

6. Layering

These projects have advantages over traditional building, including reduced labor costs and more accurate construction based on computerized plans. These projects are frequently completed significantly more quickly; some homes can be constructed in a single day (though more time is required for finishing, fixtures, and additional components).

Construction businesses frequently print building components using layering. After that, they transport these components to the construction site and install them alongside standard technique components.

7. Making Separate Components

3D printing in construction may produce smaller components as well, although cement-based 3D printing is capable of producing a full house or prefabricating parts that building companies can assemble on site.

Rather than depending on pre-fabricated hardware, 3D components printing has the advantage of being able to generate bespoke elements that match the unique needs of a particular project. By producing these parts on-site or close to the construction site, you may cut down on transportation expenses and avoid delays brought on by shipping extra parts.

Additionally, by producing parts as needed, construction teams can prevent waste issues caused by ordering an excessive number of unwanted items during construction.

8. Modeling

With a few significant exceptions, prototyping and modeling are identical processes. During the design phase, architectural modeling concentrates on the artistic and visual elements of building plans. For example, it might draw attention to the structure’s most appealing features.

When trying to attract investors for a project or to show current stakeholders what the building will look like when it’s finished, modeling might be helpful.

Similar to prototyping, modeling enables architects to refine the design’s visual components prior to construction. Using architectural drawings as a guide, this is one of the applications of 3D printing in construction that can assist in creating a more accurate model depiction. Additionally, it can expedite the modeling process and enable architects to rapidly create many models in order to evaluate various design concepts.

Conclusion

Building techniques are always changing to become more sustainable and efficient. The method of creating new infrastructures can be completely changed by applications of 3D printing in construction that. 3D printing has enormous promise in the building industry. With its promise of more sustainable building processes, quicker construction timeframes, and innovative designs, it keeps revolutionizing the industry.

One of the most interesting uses of 3D printing technology is in the building sector. Thousands of square feet or more of multistory houses, offices, and other structures may now be constructed entirely with applications of 3D printing in construction. When compared to traditional constructions, 3D-printed structures can be constructed with a fraction of the time, labor, and materials. Little 3D-printed homes are being built in less than a day.

In addition to offering a potential remedy for the shortage of cheap housing, 3D printed buildings could also serve as a means of implementing time- and money-bound urbanization projects. One of the biggest developments in civil engineering today’s construction and design is the enormous potential of 3D-printed buildings.

FAQs

What is 3D Printing in Construction and how does it Work?

- Answer: In the building industry, 3D printing builds structures by layering materials according to computer models. Layer by layer, materials like as metals, polymers, or cement are deposited, guided by CAD software.

What are the Different Types of 3D Printing Technologies Used in Construction?

- Answer:

- Robotic Arm Extruders: These machines extrude layers of material using robotic arms.

- Sand layering: Uses sand that has been bound together with a substance to create constructions.

- Additive Welding: Welds metal layers to create components.

- Powder Binding: Solidifies powder layers by using a binding agent.

What are some Practical Applications of 3D Printing in Construction?

- Answer:

- Flexible Building Components: Robotic Arm Extrusion.

- 3D Concrete Printing: Constructional components and details.

- Prototyping: Establishing models for design and cost estimation.

- Additive Welding: Complex metal parts.

- Powder Binding: Multi-material patterns with intricate details.

How does 3D Printing in Construction Impact Project Efficiency and Costs?

- Answer: It can cut costs and increase efficiency since it expedites building, minimizes errors, and reduces waste.

Suggested article for reading:

Construction Robotics; 2024 Guide

The Role of Climbing and Inspection Robots in Construction Safety; 2024 Guide

Top 7 Robotic Welding and Fabrication Types in Construction (2024)

Bricklaying Robots in Construction Automation; 2024 Guide

Resources:

JKCement | FluidConstructions | Kreo | Indeed

For all the pictures: Freepik | Pixabay