Exclusive Neuroject Article: In the realm of AI for Construction Vehicle Automation, neural networks play a crucial role. These machine learning algorithms draw inspiration from the human brain and consist of interconnected nodes known as neurons. Working collectively, these neurons learn from data and can effectively tackle a wide range of challenges in the construction industry. Some notable applications include obstacle detection and avoidance, task planning and execution, as well as problem monitoring and diagnosis.

This blog article focuses on exploring the utilization of neural networks and machine learning techniques in automating construction vehicles. Specifically, we will delve into their impact on operations involving cranes, concrete delivery, and excavation. By embracing AI for construction, the industry is poised to achieve unprecedented levels of effectiveness, security, and productivity. This transformative technology has the potential to revolutionize how construction trucks operate and reshape the future of the field.

Table of Contents

How AI is Changing the Construction Industry?

Artificial intelligence (AI) is rapidly transforming the construction industry, bringing new levels of efficiency, safety, and sustainability to projects of all sizes. Here are some of the ways that AI for construction is changing the construction industry:

Improved safety: AI-powered cameras and sensors can monitor construction sites for potential hazards, such as falls, collisions, and exposure to harmful materials. This can help to prevent accidents and injuries, which are a major problem in the construction industry.

Productivity: AI-powered robots can automate tasks that are currently done by humans, such as bricklaying, welding, and painting. This can free up workers to focus on more complex tasks, leading to increased productivity.

Enhanced sustainability: AI in construction can be used to design and build more sustainable buildings, by optimizing energy efficiency, water usage, and waste disposal. This can help to reduce the environmental impact of construction projects.

Improved quality: AI for construction can be used to identify and correct errors in design and construction, leading to higher-quality buildings. This can save time and money in the long run.

Innovation: AI for construction is helping to drive innovation in the construction industry. For example, AI for construction is being used to develop new construction methods, such as 3D printing. This is leading to new and more efficient ways to build.

These are just a few of the ways that AI for construction is changing the construction industry. As technology continues to develop, we can expect to see even more innovative applications of AI in the years to come. Here are some specific examples of how AI for construction is being used in the construction industry today:

Site safety: AI-powered cameras and sensors can be used to monitor construction sites for potential hazards, such as falls, collisions, and exposure to harmful materials. This can help to prevent accidents and injuries, which are a major problem in the construction industry. For example, the company SiteAware uses AI for construction to analyze video footage from construction sites to identify potential safety hazards. This information is then used to alert workers and managers to potential dangers.

Robotics: AI for construction is being used to develop robots that can perform tasks on construction sites, such as bricklaying, welding, and painting. These robots can be more precise and efficient than human workers, and they can also work in dangerous or difficult-to-access areas. For example, the company Construction Robotics has developed a robot that can lay bricks faster and more accurately than human workers.

Project management: AI for construction can be used to optimize the allocation of labor and materials, making the scheduling of construction tasks more efficient and cost-effective. For example, the company Procore uses AI for construction to analyze data from construction projects to identify potential problems and delays. This information is then used to help project managers make better decisions about how to allocate resources.

Building performance: AI for construction can be used to analyze data from building systems to optimize energy efficiency, indoor air quality, and other performance metrics. For example, the company BuildingIQ uses AI to monitor and manage the energy consumption of buildings. This information is then used to help building owners reduce their energy costs.

These are just a few of the many ways that AI for construction is being used in the construction industry today. As technology continues to develop, we can expect to see even more innovation in this area in the years to Come.

Suggested article for reading: Construction Monitoring

Fundamentals of Neural Networks in AI for Construction Vehicle Automation

Neural networks are a type of machine learning algorithm that is inspired by the human brain. They are made up of interconnected nodes, called neurons, that work together to learn from data. The fundamentals of neural networks in AI for construction are:

Artificial neurons: The basic building block of a neural network are the artificial neuron. An artificial neuron is a mathematical function that takes a set of inputs and produces an output.

Neural network architecture: A neural network is made up of several artificial neurons that are connected in a specific way. The architecture of a neural network determines how it learns and makes predictions.

Training a neural network: Neural networks are trained on data. The training process involves adjusting the weights of the artificial neurons in the neural network so that it can make accurate predictions.

Applications of neural networks in construction: Neural networks can be used to solve a wide variety of problems in the construction industry. Some of the most common applications of neural networks in construction include predicting construction costs, identifying potential defects, optimizing construction schedules, and automating construction tasks.

Neural networks can be used to solve a wide variety of problems in the construction industry, including:

Predicting construction costs: Neural networks can be trained on historical data to predict the cost of future construction projects. This can help to improve project budgeting and planning.

Identifying potential defects: Neural networks can be used to analyze images and videos of construction projects to identify potential defects. This can help to prevent costly repairs and improve the quality of construction projects.

Optimizing construction schedules: Neural networks can be used to analyze data from construction projects to identify potential bottlenecks and optimize the scheduling of tasks. This can help to save time and money.

Automating construction tasks: Neural networks can be used to automate tasks such as scheduling, planning, and quality control. This can free up human workers to focus on more creative and strategic tasks.

Neural networks are a powerful tool that can be used to improve the efficiency, safety, and sustainability of construction projects as AI for construction. As the technology continues to develop, we can expect to see even more innovative applications of neural networks in the construction industry in the years to come.

Suggested article for reading: Building Automation System (BAS)

Integration of Neural Networks into Construction Machinery

The integration of neural networks into construction machinery is a promising new technology that has the potential to improve safety, efficiency, and sustainability in the construction industry.

There are several ways that neural networks can be integrated into construction machinery. For example, neural networks can be used to:

- Power the sensors and cameras that detect and avoid obstacles.

- Provide the intelligence that plans and executes tasks.

- Monitor the health of the machinery and diagnose problems.

- The integration of neural networks into construction machinery is still in its early stages, but the potential benefits are significant.

Some of the challenges that need to be addressed in order to integrate neural networks into construction machinery include:

- The need for large amounts of training data. Neural networks need to be trained on large amounts of data in order to learn how to perform tasks accurately. This can be a challenge in the construction industry, where data is often scarce or difficult to obtain.

- The need for powerful computing resources. Neural networks can be computationally expensive to train and run. This can be a challenge for construction companies that do not have access to powerful computing resources.

- The need for safety and reliability. Neural networks must be safe and reliable in order to be used in construction machinery. This means that they must be able to operate correctly even in challenging conditions, such as dust, dirt, and extreme temperatures.

Despite these challenges, the integration of neural networks into construction machinery is a promising new technology with the potential to revolutionize the construction industry. As the technology continues to develop, we can expect to see even more innovative applications of neural networks in the construction industry in the years to come.

The integration of neural networks into construction machinery is a promising new technology with the potential to make the construction industry safer, more efficient, and more sustainable.

Machine Learning Techniques in Construction Vehicle Automation

Machine learning in construction refers to the application of artificial intelligence techniques that enable software applications to make accurate predictions without explicit programming. By utilizing historical data, machine learning algorithms can generate new output values.

In the construction industry, machine learning techniques are employed to automate construction vehicles. This automation can be applied to various tasks, including:

Detecting and avoiding obstacles: ML algorithms can be used to analyze images and videos from construction sites to identify potential obstacles, such as workers, other vehicles, and materials. This can help to prevent accidents and injuries.

Planning and executing tasks: ML algorithms can be used to plan and execute tasks, such as loading and unloading materials, digging, and pouring concrete. This can help to improve efficiency and productivity.

Monitoring and diagnosing problems: ML algorithms can be used to monitor construction vehicles for problems, such as leaks, overheating, and mechanical failures. This can help to prevent costly repairs and downtime.

There are several different ML techniques that can be used for construction vehicle automation. Some of the most common techniques include:

Supervised learning: Supervised learning algorithms are trained on labeled data. This means that the data has been tagged with the correct output values. Supervised learning algorithms can be used to perform a variety of tasks, such as classification, regression, and clustering.

Unsupervised learning: Unsupervised learning algorithms are trained on unlabeled data. This means that the data does not have any tags. Unsupervised learning algorithms can be used to perform tasks such as dimensionality reduction, clustering, and anomaly detection.

Reinforcement learning: Reinforcement learning algorithms learn by trial and error. They are given a reward for taking actions that lead to desired outcomes and a penalty for taking actions that lead to undesired outcomes. Reinforcement learning algorithms can be used to perform tasks such as playing games and controlling robots.

The use of ML techniques in construction vehicle automation is still in its early stages, but the potential benefits are significant. As the technology continues to develop, we can expect to see even more innovative applications of ML in the construction industry in the years to come.

Here are some of the potential benefits of using ML techniques in construction vehicle automation:

Improved safety: ML algorithms can help to prevent accidents and injuries by detecting and avoiding obstacles.

Increased productivity: ML algorithms can help to improve productivity by automating tasks and optimizing schedules.

Reduced costs: ML algorithms can help to reduce costs by preventing costly repairs and downtime.

Improved sustainability: ML algorithms can help to improve sustainability by optimizing the use of resources and reducing waste.

The use of ML techniques in construction vehicle automation is a promising new technology with the potential to make the construction industry safer, more efficient, and more sustainable. As the technology continues to develop, we can expect to see even more innovative applications of ML in the construction industry in the years to come.

Some of the challenges that need to be addressed in order to use ML techniques in construction vehicle automation include:

- The need for large amounts of training data: ML algorithms need to be trained on large amounts of data in order to learn how to perform tasks accurately. This can be a challenge in the construction industry, where data is often scarce or difficult to obtain.

- The need for powerful computing resources: ML algorithms can be computationally expensive to train and run. This can be a challenge for construction companies that do not have access to powerful computing resources.

- The need for safety and reliability: ML algorithms must be safe and reliable in order to be used in construction vehicles. This means that they must be able to operate correctly even in challenging conditions, such as dust, dirt, and extreme temperatures.

Despite these challenges, the use of ML techniques in construction vehicle automation is a promising new technology with the potential to revolutionize the construction industry. As the technology continues to develop, we can expect to see even more innovative applications of ML in the construction industry in the years to come.

Suggested article’s for reading: Top 21 Sustainable Buildings | Sustainable Architecture

Human-Robot Interaction in Automated Construction Vehicles

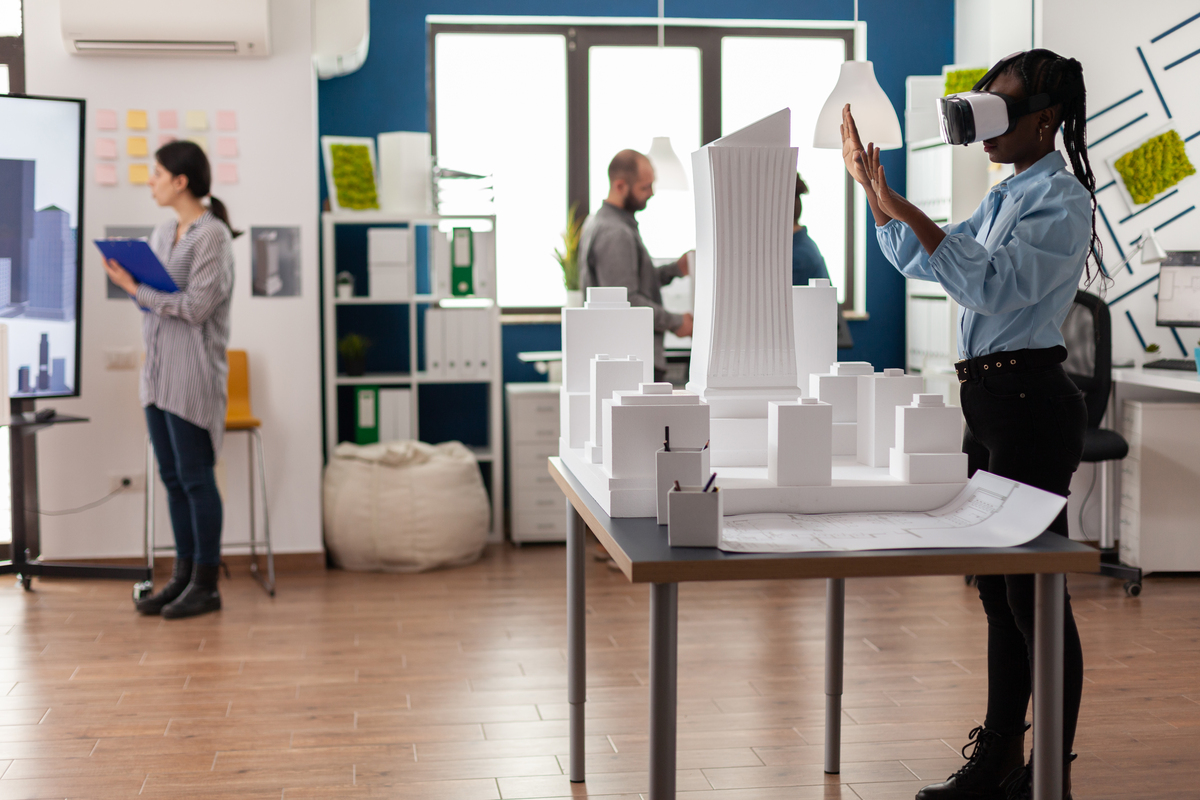

Human-robot interaction (HRI) in automated construction vehicles is a rapidly growing field of research. As the capabilities of construction robots continue to improve, there is a growing interest in how humans and robots can work together safely and effectively.

There are several potential benefits to HRI in automated construction vehicles. Robots can perform dangerous or repetitive tasks that are difficult or hazardous for humans. They can also work in difficult or confined spaces that are inaccessible to humans. This can help to improve safety, productivity, and efficiency on construction sites.

However, there are also a few challenges that need to be addressed in order to successfully implement HRI in automated construction vehicles. These challenges include:

Safety: It is essential to ensure that the interaction between humans and robots is safe. Robots need to be able to detect and avoid humans, and humans need to be aware of the presence of robots in their workspace.

Communication: Humans and robots need to be able to communicate effectively with each other. This includes both verbal communication and nonverbal communication, such as gestures and facial expressions.

Trust: Humans need to trust that robots will perform their tasks safely and reliably. Robots need to be able to demonstrate that they are trustworthy.

Several research projects are underway to address these challenges and to develop effective HRI solutions for automated construction vehicles. These projects are using a variety of approaches, including:

Developing new sensors and algorithms that allow robots to detect and avoid humans.

Designing robots that are easy for humans to understand and interact with.

Testing and evaluating different HRI approaches in real-world construction environments.

The results of these research projects are promising, and they suggest that HRI has the potential to significantly improve the safety, productivity, and efficiency of construction sites. As the technology continues to develop, we can expect to see even more widespread adoption of HRI in automated construction vehicles in the years to come.

Case Studies: Applications of AI for Construction in Vehicle Automation

The integration of artificial intelligence (AI) technology has led to considerable automation improvements in the construction sector in recent years. AI for construction has already shown promise in a number of fields, like the automation of construction vehicles. AI is transforming the way construction vehicles function, bringing greater efficiency, safety, and productivity—from self-driving bulldozers to self-driving concrete mixers. Here are several fascinating case studies that demonstrate how AI for construction is being used in the construction industry to automate vehicles.

Case Study 1: Autonomous Excavators

The partnership between Built Robotics and Mortenson Construction is one such instance. Built Robotics created an AI for construction retrofit kit that can be placed on regular excavators to give them the ability to work independently. These excavators can navigate building sites, dig trenches precisely, and level terrain without human assistance since they are outfitted with cameras, lidar sensors, and GPS. These autonomous excavators can operate around the clock without the need for human operators, increasing production and lowering labor expenses.

Case Study 2: Self-Driving Concrete Mixers

The partnership between ASI Robotics and Skanska, a prestigious construction firm, serves as an example of a successful deployment. Concrete was efficiently supplied to various areas on the construction site by the self-driving mixers, decreasing human error and accident risk. Additionally, the concrete mix was optimized by the vehicles, assuring consistent quality throughout the project.

Case Study 3: Intelligent Crane Systems

One noteworthy instance is the intelligent crane system from Liebherr, which uses AI for construction to identify probable collisions and automatically alters the crane’s movement to prevent mishaps. The technology employs computer vision to recognize impediments and warns the crane operator visually and audibly when one is present. By eliminating downtime brought on by collisions or damage, this device greatly lowers the risk of accidents while increasing production.

Case Study 4: Access control using facial recognition

AI-based navigation has improved over time and now helps drivers by assessing the environment and recommending the best routes. Additionally, the motorist is alerted if a pothole or hump is coming, preventing them from being caught off guard. For drivers, especially those who commute through congested areas, this information is priceless.

Case Study 5: Automated replenishment

The current trendsetters are AI-based algorithms that generate demand and supply sets using data science. The auto-replenishment AI for construction platforms combines simulation and replenishment to produce autonomous and optimum solutions because every data collection will contain flaws. In order to prevent stock shortages and excess inventory, the majority of automakers are using MILP (Mixed Integer Linear Programming) competent tools that can employ a variety of factors and combine them with simulations.

Case Study 6: Collaborative robots

The construction industry’s production is also being impacted by AI for construction. To increase overall efficiency and deliver superior results, they combine robots, human-machine interactions, and quality control measures.

Case Study 7: Generative Design

To produce more reliable, long-lasting, and environmentally friendly automobile parts, forward-thinking automotive manufacturing businesses are already utilizing generative design. Based on the set of criteria specified by designers and engineers, AI-based design systems can produce hundreds of design variations for a given component.

Case Study 8: Marketing automation

Today, marketers for construction companies must have AI for construction. Marketing experts may find new chances for cross-selling and upselling, automate lead management, tailor advertisements, estimate demand and sales, and enhance marketing tactics by analyzing client purchase cycles and social media data.

The construction industry is changing as a result of the use of AI for construction automation, which has improved productivity, safety, and efficiency across a variety of construction operations. We can see the enormous influence of AI technology through case studies involving autonomous excavators, self-driving concrete mixers, and intelligent crane systems.

Construction organizations may streamline operations, cut costs, and enhance project outcomes by utilizing AI’s capabilities. Continuous operation of autonomous cars boosts productivity, and AI systems improve safety by reducing human error and spotting possible dangers. Additionally, the use of AI for construction trucks provides real-time data analysis, improving resource allocation and enabling better decision-making.

What Is the Impact of AI on Human Jobs?

The effect of AI for construction on human employment is a hotly contested subject. While there is no doubt that AI for construction technologies has changed several industries and resulted in tremendous improvements, there are worries regarding the potential replacement of human workers. A thorough research, however, indicates that the effect of AI for construction on employment is more varied and complex than a straightforward replacement scenario.

It is crucial to first acknowledge that AI technologies have the potential to automate tedious and repetitive jobs, freeing up human workers to concentrate on more challenging and creative projects. AI for construction has the potential to increase production, improve efficiency, and free up human labor for higher-value tasks that call for analytical thinking, problem-solving, and emotional intelligence.

Additionally, AI technologies frequently enhance human abilities, resulting in new career prospects and work roles. As AI for construction systems advance in sophistication, they can support human decision-makers by providing insightful data analysis and facilitating more strategic and informed decisions. In order to achieve more successful results, collaborative models are growing across a variety of industries, such as healthcare, finance, and customer service.

Automation may have an influence on some job roles, but AI for construction is also creating new businesses and opportunities. Data scientists, machine learners, and experts in AI ethics are needed for the creation, deployment, and maintenance of AI technology. Additionally, opportunities for business owners, consultants, and AI specialists are presented by the rising demand for services and solutions related to AI for construction.

In order to prepare the workforce for success in the age of AI for construction, it is critical to recognize the significance of upskilling and reskilling efforts. By encouraging a culture of lifelong learning and offering training programs, people may adapt to the shifting nature of the labor market and acquire highly sought-after skills. Investments in education, training, and reemployment programs made by governments, academic institutions, and corporations are essential to advancing these initiatives.

In conclusion, there are numerous ways that AI for construction will affect human employment. Even if fears about job loss may exist, automation, augmentation, and the introduction of new opportunities are more likely to have a positive overall impact. Societies can gain from increased productivity, innovation, and enhanced quality of life by utilizing AI technology effectively and embracing the possibilities for human-AI collaboration.

Resources:

Microsoft | Explodingtopics | itransition | Built Robatics | ASI Robots | SKANSKA | Liebherr | We Forum | NBER | McKinsey |

For all the pictures: Freepik