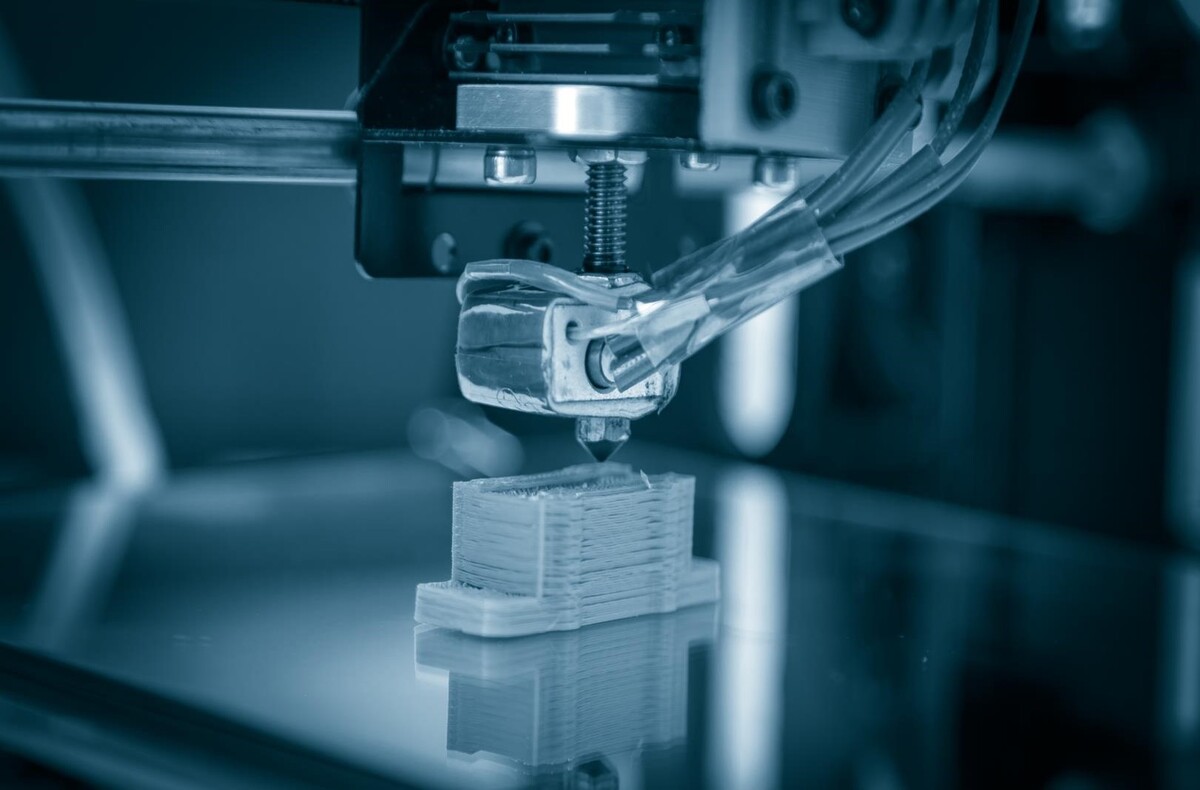

The adoption of new technology in the building industry is sluggish, especially as construction robots. However, 3D printing has surfaced as a viable remedy for a number of the industry’s problems in recent years. Additive manufacturing, also referred to as 3D printing, is the technique of building an object piece by piece by layering down successive cross-sectional layers of material.

Among other industries, the automobile and aerospace sectors have been using this method for decades. But only recently has its potential for construction been investigated. Technology has the power to completely change how we plan and construct buildings, making the process quicker, more effective, and more environmentally friendly.

There are numerous ways that 3D printing robots might help the building sector. First of all, it enables parts and components to be customized for a particular project, providing more design freedom and enhanced performance. Second, utilizing just the quantity of material required to construct a structure, can greatly reduce waste, resulting in financial savings and increased sustainability. Furthermore, because parts and components may be created swiftly on-site, it can expedite the construction process and, in the end, speed up project completion. Additionally, printing can increase safety by lowering the amount of risky tasks employees perform.

Finally, though 3D printing robots can have a large upfront cost, throughout the equipment’s lifetime, its efficiency and other benefits result in cost savings. All things considered, 3D printing is a promising technology for the construction sector as a whole because of its potential advantages.

Table of Contents

Types of 3D Printing Robots

There are two types of 3D printing robots called Robotic Arm and Gantry System:

Robotic Arm

printer that is automatically controlled, giving you flexibility in moving about and scheduling several chores at once. Compared to conventional 3D printing robots, the arm can print in greater sizes and from a variety of angles, enabling the realization of complex geometries and curves.

Gantry System

Construction uses of 3D printing robots began with the contouring technique. Building materials are deposited in this manner to produce large-scale constructions with a smooth surface finish and a 3D model. It operates by using rails positioned all over the building’s floor to guide the robotic arm as it applies concrete layer by layer.

Suggested articles to read: The Role of Climbing and Inspection Robots in Construction Safety; 2024 Guide

How is 3D Printing Robots Used in Construction?

Generally speaking, a construction 3D printing (C3DP) project begins with a 3D digital model of the structure that has to be built. Layers are almost cut out of the model. Subsequently, the printing robot or gantry system deposits the material layer by layer along a pre-programmed path, tracking the layer outlines and extruding material until the entire slice is done. After finishing one layer, the next is erected on top of the previous, and so on until the entire structure is constructed. It may assemble this three-dimensional structure from metal, polymers, or concrete.

The most widely used 3D printing robot in construction is a robotic arm that moves back and forth and extrudes concrete. Other techniques for 3D printing robots in buildings include powder binding and additive welding. In powder binding, layers of powder are solidified to produce the desired object. In Amsterdam, a working, full-scale metal bridge was printed as an example of additive welding. To date, homes, workplaces, and other structures have been printed using 3D printing technology.

Suggested article to read: Top 7 Robotic Welding and Fabrication Types in Construction (2024)

Methods

There isn’t a single 3D printing robot technology that works for everyone. Several printing techniques can be used, depending on the project’s details. The most typical ones are these:

Extrusion: Because it works in nearly every setting, extrusion is the most widely used 3D printing method. This technique, which is frequently used for modeling, prototyping, and production applications, layers material back and forth via one or more nozzles that are fixed on a robotic arm, gantry system, or crane to produce an object.

Powder Bonding: Contrary to other 3D printing robots construction methods, powder bonding uses powdered raw material as its main component. Powder bed jetting and binder jetting are the two techniques. In the first, a coated sheet adds additional material with each subsequent layer, and dust particles are melted using a laser layer by layer on the desired item.

In contrast, a print head used in binder jetting applies a liquid adhesive solution to the powder printing bed. The liquid forms each layer of the desired object by binding the powder particles together. The procedure is then carried out layer by layer after the addition of a new layer. This one can handle more intricate prints and permits printing with a greater degree of accuracy.

Spray: The self-governing robot applies pressure on the building material in the required form, layer by layer. This technique makes it possible to pour concrete into the voids in the building, and its application is currently being researched for prominent, vertical uses such as ceiling or facade decorations.

Materials

Selecting the material to be utilized is the next step after deciding on the 3D-printed building process. New developments in 3D printing for construction have expanded the range of available materials. The type of project at hand should determine the material chosen, however the following are the most frequently used materials:

- Standard concrete

- Proprietary concrete mixes

- Mortar

- Plastic

- Metal

- Local natural materials (stone, sand, mud, rice waste, etc.)

Benefits of 3D Printing Robots in the Construction Industry

Since 3D printing robots affect practically every link in the construction industry’s value chain, it has enormous advantages for the sector. This technology revolutionized the way we create by improving efficiency, promoting sustainability, and assisting with supply chain difficulties.

1. Time Reduction

A project using traditional building methods can take many months to finish; major projects often take 20% longer than anticipated and incur cost overruns of up to 80% of the original budget. But thanks to 3D printing, a project may be finished in a matter of hours or days, depending on its size, and up to 70% less time is required overall. As a result, contractors can take on additional projects, which will expand their revenue stream.

Suggested article to read: What is Robotic Material Handling? 2024 Guide

2. More Economical and Long-lasting

By precisely measuring the material needed to raise a building, 3D printing robots reduce waste production on the construction site by up to 60%. In the same way, assuming lower prices for the materials’ acquisition and subsequent storage, there won’t be any excess money spent on them.

Businesses will gain exponentially more from this technology by cutting expenses and time. It is especially helpful in areas where labor is in low supply and projects are needed. Businesses can save up to 80% on labor costs by using 3D printers to automate the construction process.

3. More Secure

According to the U.S. Occupational Safety and Health Administration (OSHA), falls and unintentional contact with equipment are the leading causes of injuries among construction site workers, accounting for one out of every ten injuries sustained annually. The health and safety of the workers on the job site are among the most significant advantages that 3D printing robots have given to the construction industry. Employees can complete tasks more quickly and prevent workplace accidents by learning how to use printers efficiently.

4. Flexibility in Design

Compared to traditional production methods, 3D printing robots allow for significantly more complex shapes and patterns. In contrast to more antiquated techniques that depend on recycling blueprints and templates, 3D printing lets you design unique solutions. Using cutting-edge software, architects may create creative printed structures. For example, the models are simply modifiable in the software and printed to match if consumers require specific designs or unusual shapes for their homes or offices. Compared to conventional construction methods, this procedure takes less human labor and has little effect on cost.

Disadvantages of 3D Printing Robots for Construction

While 3D printing robots offer numerous benefits to the building sector, there are certain disadvantages as well. Among these are a few of these:

1. High Investment Costs

Investing in 3D printing robots whether to buy or rent, can be highly costly. The logistical difficulties of moving big 3D printers to locations of employment also exist. The initial cost of the printers must be considered, in addition to continuing costs for supplies and upkeep. Because of this, many professionals in the construction industry find it difficult to balance the potential benefits of 3D printing technology against its cost.

2. Labor Shortage

Although the construction sector is expanding, there is a dearth of qualified laborers. An even more specialized set of talents is needed for 3D printing robots, and finding them from a candidate pool that is already small and specialized could be challenging. Because of this, worker shortages are expected to persist for some time to come.

3. Quality Control

Although 3D printing robot technology may create intricate structures and personalized designs, it can be difficult to preserve the end product’s quality. In conventional construction, managers review the work of their employees to look for flaws or quality issues. However, because 3D printing is automated, the accuracy and precision of the printer are crucial to the manufacturing process. The quality of the finished product can also be impacted by the quality of the raw materials.

It might be difficult to make sure that 3D-printed materials adhere to the stringent requirements set by the construction industry for building materials. There are currently no common quality control standards to evaluate printing materials.

Suggested article to read: Robotic Excavators and Diggers in Construction Automation

4. Regulation Challenges

It’s still unclear whether regulations apply to 3D printing in the construction industry. The fast adoption of the technology is significantly hampered by the absence of government control. It will be difficult to incorporate 3D printing robots technology into the conventional construction project management procedure. Updating building codes to include new technologies requires a significant amount of time and political will. The ultimate goal is to create a construction 3D printing building code that applies to all municipalities.

Opportunities and Challenges for 3D Printing Robots in Construction

Gaining more traction in the market for 3D printing robots is still a struggle, even though its advantages in the construction industry will only grow as more businesses invest in this technology.

We draw attention to the following factors that prevent this technology from becoming even more popular among business experts and explain why big businesses are still hesitant to use it:

- Large firms continue to not place a substantial bet on 3D printing due to the high cost of the necessary apparatus, even though the technology itself is more cost-effective when building.

- To manage the technology underlying 3D printing, the industry has to produce more skilled workers who can operate the machinery, build computer models, and perform routine maintenance.

- More regulations and legislation are needed for 3D printing robots in construction that allow for clear guidelines on its use and benefits of its implementation in new construction sites.

Furthermore, since there is a finite amount of time to print the material, the open time—the duration during which printing and buildability are consistent within allowable tolerances—becomes a major obstacle. Concrete will solidify if the process is delayed, which will make the work more difficult.

Future of 3D Printing in Construction

Like several other inventions that are upending the way we work and produce, 3D printing takes longer to get established in the market. The benefits to the environment and the reduction in time and expense are quite promising. We anticipate a rise in the inventiveness of contractors using computer-generated, three-dimensional materials in their construction projects with every year that goes by. The urge to build homes and businesses beyond our wildest dreams will accompany this inventiveness.

We have always been able to come up with creative solutions to improve our procedures. Among many other uses, 3D printing robots for construction are the newest. Consider how you might profit from this technology as you sit and observe the developments. Everyone can think creatively and make room to take advantage of these developments. Learn as much as you can about 3D printing technology and how it’s changing the bright future of the construction industry, even if you take your time.

Suggested article to read: What are Demolition Robots in Construction? 2024 Guide

Conclusion

In essence, it’s the process of using additive manufacturing to construct a building. A software application is used in construction to direct the 3D printing robots as to what has to be printed and how big the project should be. The material is layered appropriately by the printers. Commonly utilized materials include cement, liquid metals, polymers, and other types. The construction business has enormous potential for growth thanks to 3D printing. It offers numerous benefits to businesses, communities, and the environment in addition to expediting the creation process.

In the building industry, 3D printing robots refer to the practice of layering materials one after another using computer-controlled procedures to produce three-dimensional structures. 3D printing robots help produce components off-site for later assembly or for building new buildings on the spot. The printer uses materials like cement, plastic, or liquid metals to produce the structure on a platform after receiving the dimensions from a software program.

Indeed, 3D printing is here to stay. Its potential in the building sector is too significant to ignore. The compelling data simply serves to highlight how well-positioned it is to be an effective way to improve the efficiency of the construction process, particularly in the years to come.

Suggested article for reading:

Smart Building Technology; 2024 Guide

Futuristic Construction; Everything You need to know in 2024

Resources:

Indeed | MakerCarL3d | SME | ConstructConnect | Xometry | CemexVentures | Sculpteo | Linkedin

For all the pictures: Freepik