Exclusive Neuroject Article: Conventional techniques for constructing houses may have undergone alterations over the past two centuries, but one fundamental aspect has remained constant: human involvement. Despite the utilization of modern excavators and cranes, human operators are still necessary to operate them. However, the advent of industrial 3D printers has revolutionized the process. These enormous 3D printers have the capability to autonomously produce houses, paving the way for the era of 3D Printed Houses.

In a matter of hours, they can construct an entire house using the innovative technique of 3D printing, dramatically altering our traditional perceptions of home construction. The advent of 3D Printed Houses presents an unprecedented opportunity to construct dwellings with increased speed, enhanced precision, and reduced costs.

In this discussion, we will explore a selection of fascinating existing projects involving this innovative technology. Additionally, we will highlight the efforts of various 3D printer companies diligently working to bring this revolution to the commercial market. Let’s take a look at the evolution of 3D printing in construction

Table of Contents

1. Apis Cor’s project in Dubai

In recent times, Dubai has shown great enthusiasm towards 3D printing and the potential of 3D Printed Houses. The nation has set brave and high-reaching targets to make 25% of its buildings 3D printed in the approaching years, and the signs of this are evident in the newest undertaking. Apis Cor worked in conjunction with the Dubai Municipality to construct a building – reportedly for management functions – that includes two floors and a highly intricate architectural design.

This, however, seems to be just the initial move in a broader objective shared between Dubai and Apis Cor towards the realization of widespread 3D Printed Houses. The building was reportedly a simple experiment to determine if the printer and its concrete substance could withstand Dubai’s severe weather conditions. If everything goes as planned, this could pave the way for the 3D printing of high-rise buildings, residential complexes, and iconic landmarks.

We anticipate a lot more from Apis Cor in Dubai as they view this building as merely a trial run for bigger 3D Printed Houses ventures in the future. It was designed as a proving ground to see if Apis Cor’s concrete 3D printer could successfully print a building in the intense heat of Dubai — and it triumphantly passed the test.

2. First occupied 3D-printed house in France

In July 2018, a family from France became the first to reside in a 3D Printed House, specifically a four-bedroom home. This was a joint venture involving the city council, a housing association, and the University of Nantes. The objective was to create a prototype, with the ultimate aim of manufacturing 3D Printed Houses that are more affordable and quicker to construct than conventional houses. The house was priced at approximately £176,000, which is 20% less than the cost of traditional construction.

This 1022 square foot 3D Printed House was constructed in 54 hours — this, however, only included the basic structure. It took an extra four months to install the windows, doors, and other components before the house was ready. The team responsible for this remarkable feat now think they could build a similar house in just 33 hours, attributing this to gained experience and advancements in technology.

Benoit Furet, the driving force behind the project, is convinced that 3D Printed Houses could be a viable solution to the escalating housing deficit and potentially serve as an option for social housing in the future. Furthermore, he asserts that with increasing economies of scale and advancements in technology, 3D-Printed-Houses could become 40% less expensive to construct within a decade or a decade and a half.

Yet, possibly the most intriguing aspect of this construction is its architecture – the 3D Printed House was designed to wind around trees that are under environmental protection. Such a design is nearly impossible with conventional construction due to the limitations imposed by the shape of bricks. However, 3D homebuilding can create curved shapes without any problem. This opens up possibilities for more captivating designs and the creation of custom houses tailored to the needs of people with disabilities.

3. Built in 24 Hours by Apis Cor

Perhaps the most well-known and widely shared example of 3D Printed Houses, this uniquely shaped house was erected back in 2017 in merely one day – during a snowfall, no less! The team reported that the total cost of the build, including furnishing with windows and doors, was slightly over $10,000. However, we’ll delve into why these numbers might not fully represent the whole picture later in this article.

This viral sensation certainly served as a wake-up call for the world to the potential of 3D Printed Houses in the future. The video not only demonstrated the feasibility of the concept but also showcased how 3D printed residences could be constructed faster and at a significantly lower cost than traditional methods.

Apis Cor’s build catapulted 3D Printed Houses into the public consciousness, stimulating wider participation and democratizing the field of 3D printed home construction.

4. 3D Printed House in Austin, Texas USA

Another recent viral sensation involves a collaboration between ICON and New Story, which gained media attention when they 3D printed a house in Texas, USA earlier this year. The prototype 3D Printed House constructed cost the companies around $10,000. However, they believe that they can reduce this cost to as low as $4,000 in future projects.

Similar to Apis Cor’s 3D Printed House in Russia, this house was built in 24 hours. It is part of ICON’s more extensive plan to contribute to the infrastructure in economically disadvantaged parts of the world by providing housing. The non-profit ICON has already built over 800 houses in Haiti, El Salvador, Bolivia, and Mexico, and has plans to use 3D printing to construct affordable 3D-Printed-Houses in these regions. ICON currently employs local workers, but there may be areas that lack the necessary skilled builders.

As a result, 3D Printed Houses present a solution to this shortage of skilled builders. Large construction 3D printers can be transported to these economically challenged areas where there is a scarcity of skilled builders to construct homes for impoverished individuals. This represents an instance of how 3D printing can enhance the lives of the most vulnerable members of society. We applaud ICON and New Story for their remarkable efforts in this domain.

This is also a project that we are quite likely to see evolve. New Story is co-founded and advised by a number of highly influential and successful individuals, including the CEO of Glassdoor, and Reddit’s Co-Founder, Alexis Ohanian. Many of those associated with the project have a history of accomplishment and effective execution, so we are eager to track the project’s progress. Since the Texas initiative, they have also produced a series of 3D Printed Houses in Mexico.

5. Redefining Suburbia, Coachella Valley

We’re all familiar with the Hollywood-famed Coachella music festival, but have you ever heard of Coachella’s 3D Printed Houses neighborhood?

Mighty Buildings, a company specializing in 3D printing construction and technology, along with Palari Group, a firm focused on sustainable real estate, are about to commence construction on what has been proclaimed as the world’s first 3D Printed Houses neighborhood by the Guardian, CNN, and other prominent news outlets.

Named Rancho Mirage, the neighborhood will be comfortably located in the undulating landscape of Coachella Valley.

Mighty Buildings and Palari Group aim to build 15 3D-Printed-Houses by 2022, each featuring three bedrooms, two bathrooms, a terrace, and a swimming pool, all within a space of 1,450 square feet.

Composed of a stone composite material, the walls of these 3D Printed Houses are claimed to fit together much like Lego pieces, as stated by Palari CEO Basil Starr.

There’s also the option for customization, allowing homeowners to add a 700-square-foot accessory dwelling unit (ADU) to the property, which will include two additional bedrooms and a bathroom.

Rancho Mirage has the potential to serve as the model for future neighborhoods, not only because of its impressive sustainability but also due to the significant solution it presents for the global housing crisis in terms of 3D-Printed-Houses.

As for upcoming news, keep a lookout for the 3D-printed school that Mighty Buildings, in collaboration with Thinking Huts, plans to open in Madagascar later this year.

6. A Masterpiece in Just Three Weeks

Kamp C, a company focused on sustainable construction, 3D printed a complete two-story 3D Printed House in Belgium’s Flanders region using Europe’s largest 3D printer. The completed two-story terraced house is just under 1,000 square feet. It’s a low-energy home equipped with a green roof, and yet, it blends perfectly with the neighboring architecture.

However, the most remarkable feature of this project is the construction process itself. For a two-story building, the construction traditionally would have been carried out in two stages, off-site in a separate facility. Instead, Kamp C brilliantly utilized the stationary COBOD BOD2 concrete printer to print this 3D Printed House on-site in one piece.

COBOD, which stands for Construction of Building on Demand, developed the BOD2 3D printer, which operates on three axes. This design allows for on-site printing in a circular pattern and, more importantly, the ability to print multiple floors of 3D Printed Houses.

But it’s not just about aesthetics. According to Marijke Aerts, the project manager at Kamp C:

Construction kicked off on March 19th, 2020, and the printing process took approximately three weeks. However, Kamp C believes that future 3D Printed Houses could be finished in just two days.

7. Office of the Future

Dubai consistently grabs headlines for its audacious and extravagant declarations of future objectives – one of the boldest being its assertion that 25% of buildings will be constructed using 3D printing by 2030. And they’re substantiating this claim with action; this office, touted as the most advanced 3D-Printed-House in the world, cost approximately $140,000 to construct (excluding finishing details) and took 17 days.

Endearingly dubbed the “office of the future”, the building was produced by a 20-foot-tall concrete 3D printer that used a robotic arm to lay down cement. Only one worker was required to oversee the 3D Printed House printer while it was printing, and seven employees worked on assembling components of the office while the printer was in operation.

Moreover, 10 electricians and other specialists labored on the office’s internal systems throughout the 17-day construction period. So, we can’t exactly call it a fully 3D Printed House, as other workers contributed to various other components. However, 3D printing has never claimed the ability to integrate complex electrical systems during the printing process, only to create the structure in record time. With this project demonstrating considerable ambition, perhaps Dubai is poised to become a global frontrunner in 3D-Printed-Houses.

8. Revolutionizing Construction with ARCS Technology

SQ4D, which captured global attention in January 2020 when they constructed what was then the world’s largest 3D Printed House, is now enchanting us once more. They have officially announced the first 3D Printed House to receive a certificate of occupancy in the United States.

The property is presently listed for sale on Zillow with a price tag of $299,999 – that’s 50% cheaper than the cost of traditionally constructed new buildings in the same area.

This two-story 3D Printed House, boasting 1,400 square feet of living space, is constructed from a unique concrete material. It offers three bedrooms, two bathrooms, and a 2.5-car covered garage.

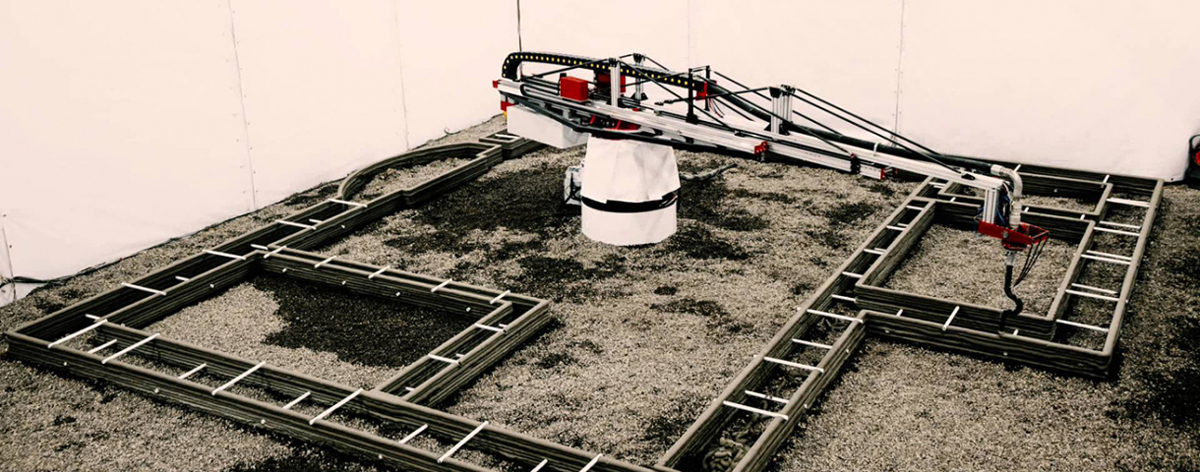

Yet, the true ingenuity lies in their patent-pending ARCS technology used in creating these 3D-Printed-Houses.

ARCS, standing for Autonomous Robotic Construction System, is a technology that uses minimal power to robotically construct the house on-site. In addition to printing the exterior and interior walls, it also prints utility conduits, siding, and sheathing, effectively reducing a full construction crew’s labor to a mere three-person job.

Using ARCS, each 3D Printed House required only 48 hours of print time spread over several weeks.

Regarding the potential and implications this technology could have for the future, Kirk Andersen, SQ4D’s director of operations, stated:

“I want people to not be afraid of automation…it is just a different tool and different method. But it’s still the same product… we can make 3D Printed Houses more affordable and safer. We can use the technology to tackle homelessness and aid in disaster relief in an eco-friendly way.”

9. Redefining Affordable Housing

Italian home 3D printing company WASP constructed ‘Gaia’, a 3D Printed House crafted from a blend of concrete and mud-based material. The 215-square-foot structure took ten days to finish, although the total time, including all furnishings and additions, would be longer. The most remarkable aspect is that this 3D Printed House only required $1,000 worth of materials to build, though this does not account for labor and other associated expenses.

Similar to New Story’s strategies for the developing world, this intriguing 3D Printed House prototype could lay the groundwork for constructing houses in less wealthy countries. In areas where the urgent need is for shelter rather than sophisticated internal wiring and plumbing, these affordable 3D Printed Houses present an effective solution to a pressing crisis.

10. 3D-printed homes in Netherlands

Project Milestone – the codename for the initiative to construct five livable and aesthetically pleasing 3D Printed Houses in Eindhoven, Netherlands – is an intriguing collaboration between Houben and Van Mierlo Architecten, Van Wijnen, and the Eindhoven University of Technology.

Launched as a response to the shortage of skilled bricklayers in the Netherlands, the first of these 3D Printed Houses – and the first 3D printed house on sale – attracted over 20 interested buyers in its initial week on the market.

While at present only the concrete structure of the 3D Printed Houses is 3D printed, it’s hoped that with technological advancements, by the time the fifth house is constructed, other features, such as drainage pipes, will also be created using the house 3D printer. This would further cut costs and promote the adoption of 3D printing in home construction.

11. Czech Republic Sets Sail with 3D-Printed Houseboats

No home design is immune to the progression of technology, as demonstrated by the Czech Republic’s adventurous venture into the realm of 3D Printed Houseboats. This 462-square-foot 3D Printed House might be small, but it carries a hefty dose of courage and sheer uniqueness.

Named the PRVOK, the 3D Printed House can accommodate two occupants, featuring a living room, kitchen, bedroom, and bathroom.

The 3D Printed House is entirely devoid of sharp angles, composed solely of curves, and is printed with an outer and inner layer with insulation sandwiched in between. The house also features eco-friendly technology, from a water-recycling shower to a green roof.

Think of it as a Hobbit home from the undulating hills of the Shire meeting the rivers of a bustling city.

The primary focus of PRVOK was on speed and efficiency, asserting that its construction is seven times faster than that of a conventional brick house.

The 3D Printed House is constructed from specially designed concrete mixed with nano-polymers that solidify faster than regular concrete. Within the initial 24 hours, it reaches the standard hardness of a brick house, and after 28 days, it’s as hard as a bridge.

It’s stated that this 3D Printed House can endure up to a century.

Without a doubt, we’re eager and optimistic about seeing these 3D Printed Houses drifting through our canals in the near future.

Discussing its functionality, the watch ensures accurate timekeeping as it syncs across five time zones. It offers water resistance up to 200m, providing strong protection against water pressure.

Resources:

3dsourced | builtin |

For all the pictures: freepik