Sustainable Digital Fabrication (SDF) in construction refers to the use of computer-guided manufacturing (3D printing, CNC cutting, robotics, etc.) combined with eco-friendly practices (recycled or bio-materials, waste minimization, energy efficiency). This approach is crucial because the building sector accounts for a massive share of emissions – roughly 37% of global greenhouse gases.

By integrating digital design and fabrication with sustainable materials and practices, the industry can cut carbon and waste while boosting performance. This article explores seven key innovations in SDF that are transforming construction: large-scale 3D printing with recycled materials; bio-based printable materials; robotic assembly that minimizes waste; parametric design for optimized material use; digital prefabrication and on-demand production; full lifecycle tracking via digital twins; and adaptive reuse through computational deconstruction.

Table of Contents

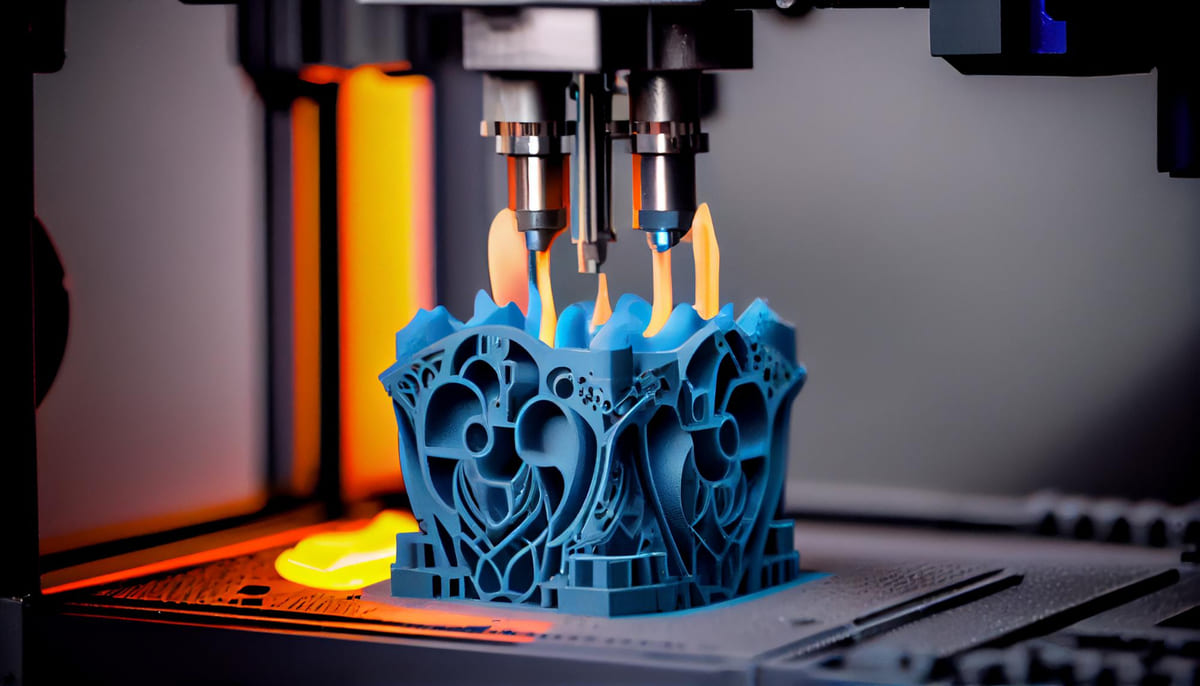

Innovation 1: Large-Scale Additive Manufacturing with Recycled Materials

Large-scale 3D-printed foam panel made from recycled waste (Airlements, ETH Zurich). Large-scale additive manufacturing uses giant 3D printers to build walls, floors or structures layer by layer. When feedstock includes recycled or waste materials, the process slashes virgin resource demand. For example, ETH Zürich’s Digital Building Technologies group developed Airlements, printing insulated wall panels from a cement-free mineral foam made from recycled plastic and mineral waste. Such panels need no molds and have a lower carbon footprint; they can be fully reused or recycled.

Chinese firm Winsun famously 3D-printed a five-story apartment block using a proprietary mix of industrial by-products and conventional aggregates. Even decorative elements like a pavilion (Trillium) have been printed from recycled ABS plastic. These examples show that additive construction can turn “trash into treasure,” repurposing demolition debris and plastics into new building components while reducing material waste and energy use.

Innovation 2: Bio-Based Printable Building Materials

Bio-based materials for printing include biopolymers, plant fibers, and organic composites derived from renewable sources. Such materials cut reliance on fossil-based cement and resins and often capture carbon as they grow. For instance, researchers at Oak Ridge National Lab and the University of Maine 3D-printed entire floor panels from biobased PLA (corn-derived polylactic acid) blended with wood flour.

These panels match steel-concrete strength yet are fully recyclable. The University of Maine’s BioHome3D project demonstrated a prototype house (floors, roof, walls) printed entirely from biodegradable resins and wood fibers; the 600 sq ft, one-bedroom building is 100% recyclable and constructed from plant-based materials. Other developments include hempcrete (lime mixed with hemp fibers) – a lightweight, carbon-negative composite – and novel hydrogels combining nanocellulose and algae that can be extruded without heating.

Mycelium (fungal root networks) is also being explored as a 3D-printable bio-binder that sequesters carbon and composts easily. Using these materials reduces embodied carbon: for example, one study suggests optimized biopolymer prints could lower embedded carbon by ~20% by replacing conventional concrete in slabs. In sum, bio-based printable mixes (wood flour, corn PLA, hemp, nanocellulose, etc.) enable truly sustainable building parts that can biodegrade or be returned to the environment with minimal impact.

Suggested article to read: Top 7 Robotic Welding and Fabrication Types in Construction (2024)

Innovation 3: Robotic Assembly and Waste Minimization

Construction robotics encompass automated machines that assemble buildings or parts (bricklaying arms, panel bots, CNC saws, etc.). High precision and repeatability enable these robots to minimize waste. For example, bricklaying robots like Construction Robotics’ SAM and Fastbrick’s Hadrian X lay bricks with sub-millimeter accuracy, eliminating human error in mortar application and layout.

In fact, Ballast Nedam’s bricklaying robot uses only about 455 grams of mortar per brick versus 1,000 grams used by manual masons, roughly halving material use. Software tracking also avoids over-ordering: exact material-quantity planning ensures no excess bricks or panels are purchased. Similarly, off-site robotic prefabrication (modular factories) cuts onsite waste dramatically: one report notes that conventional construction can generate 10–20% material waste, while factory production reduces that by up to 90% through precise cutting and reuse of leftovers.

Advanced CNC saws and nesting algorithms lay out panels to use nearly the entire sheet with minimal scrap. Combined with AI-driven sorting (e.g. ZenRobotics’ AI robots that automatically separate and reclaim construction debris), these automated systems greatly boost circularity. In short, robotic assembly ensures consistent quality and enables lean construction: work proceeds faster, errors are avoided, and every nail or brick is accounted for.

Innovation 4: Parametric Design for Material Efficiency

Parametric design uses algorithmic models to generate and optimize structures. By linking geometric parameters to engineering constraints (loads, spans, connections), parametric tools can thin out or reshape elements to use only the material needed. For example, structural designers can use generative topology optimization to remove redundant concrete, leaving an organic “lattice” that holds the same load with far less mass. Advanced CAM systems then translate these designs into precise fabrication instructions. In practice, a parametric roof panel might vary in thickness only where stresses are highest, rather than using a uniform deep slab everywhere.

This drives sustainability by slashing embodied carbon: studies have shown that parametric optimization of concrete slabs or trusses can cut material volumes by double-digit percentages. Software for nesting and cutting (often integrated with BIM) also aligns with parametric models, arranging panel cuts to maximize usage of standard board sizes and minimize off-cuts. Although parametric design is largely a planning tool, it is fundamental to sustainable fabrication: it enables architects to pursue minimal forms that meet performance needs, and ensures that CNC machines or printers execute the most efficient geometry.

Innovation 5: Digital Prefabrication and On-Demand Production

Digital prefabrication means producing building modules (walls, floors, roof sections) in factories using digital design models and then assembling them onsite. A controlled factory environment allows precise cutting, welding and assembly, which sharply reduces waste. For example, one analysis showed that prefab construction can lower material waste by up to 90%, because materials are measured and cut to exact specs offsite. Components are often built from CNC-cut panels or printed forms based on BIM, so mistakes and offcuts are minimal.

On-demand production is a further step: with digitally linked logistics, parts are manufactured only when needed, avoiding overproduction and storage. This also cuts transportation: instead of dozens of delivery trucks bringing raw lumber and panels, large prefabricated kits arrive just in time.

Companies like Worldwide Steel Buildings ship complete steel-frame kits that fit together seamlessly, engineered for zero waste. Energy use is lower too: factories optimize lighting and machinery, and quicker assembly means less on-site energy use. Overall, digital prefabrication leverages automation to build faster and greener – producing modules exactly as designed, then snapping them together, with dramatically reduced scrap and carbon footprint.

Innovation 6: Lifecycle Tracking Through Digital Twins

A digital twin is a live digital replica of a built asset, updated with sensor and process data. In sustainable fabrication, twins enable full lifecycle tracking of materials and performance. For example, a building twin can record each element’s material properties, maintenance history, and energy use. This helps optimize operation (adjusting HVAC schedules, for instance) and plan eventual deconstruction. By continuously monitoring conditions (cracks, strains, energy draw), the twin can trigger timely repairs, extending a building’s life and avoiding resource-intensive overhauls. Researchers note that proactive maintenance via digital monitoring “prolongs the lifespan of buildings and reduces the need for extensive, resource-intensive repairs”.

On the material side, digital twins can incorporate material passports: detailed inventories of all materials used. When a building is remodeled or demolished, the twin tells contractors exactly what each beam or panel is made of and where to send it (recycle, reuse, etc.). Some projects integrate twins with 5D BIM, enabling real-time tracking of carbon and waste as the building is used and eventually disassembled. In sum, lifecycle digital twins in construction support circularity by ensuring no resource is invisible or wasted: every component is cataloged and its performance tracked, maximizing reuse and minimizing embodied energy.

Innovation 7: Adaptive Reuse Through Computational Deconstruction

Computational deconstruction combines digital scanning, BIM and robotics to dismantle buildings in a resource-efficient way. Instead of blasting structures, digital tools plan how to take them apart piece by piece. For example, Urban Machine’s “The Machine” uses AI-guided robotics to strip nails and staples from reclaimed wood, yielding clean lumber ready for reuse.

Robotic deconstruction unit removing fasteners from reclaimed lumber (Urban Machine’s “The Machine”). In another concept, the ERO Concrete-Recycling Robot uses high-pressure water jets to precisely cut concrete into reusable aggregate and even salvage rebar on the spot. AI-powered sorting robots (like ZenRobotics) can automatically separate mixed demolition debris into clean streams of wood, metal and concrete.

The result is a methodical reverse-building: a scanned 3D model guides the sequence of removals, and software keeps track of each part’s identity. This means beams, bricks, and panels can flow back into supply chains rather than landfills. These adaptive reuse methods epitomize sustainable digital fabrication – using computation and machines to close the loop on construction waste and treat the existing built environment as a source of materials for the next project.

FAQs

How can sustainable digital fabrication reduce waste and environmental impact in construction?

By using precise, computer-driven processes and eco-friendly materials, Sustainable Digital Fabrication minimizes excess. For example, factory-based digital prefabrication cuts onsite waste by up to 90% because every cut is exact and leftovers can be reused. Additive 3D printing deposits material only where needed, often using recycled plastics or industrial by-products. Automated robots ensure consistent placement of bricks, panels or beams with minimal errors. Altogether, this precision means far less scrap, fewer overordered supplies, and a much smaller carbon footprint than traditional construction.

What types of bio-based materials are used in sustainable digital fabrication for buildings?

Common bio-based materials include biopolymers and plant-derived composites. For instance, researchers have 3D-printed structural panels from PLA (polylactic acid) – a plastic made from corn – mixed with, and nanocellulose/algae hydrogels that can be extruded into shapes. Mycelium (fungus root networks) is also explored as a growth-based binder for lightweight panels. These materials are renewable, often carbon-sequestering as they grow, and they biodegrade or can be reused, making them ideal for green construction.

Which sustainable digital fabrication technologies deliver the biggest environmental benefits?

All innovations contribute, but those that target material efficiency and reuse tend to have the largest impact. For example, robotic and prefabrication systems cut waste dramatically: automated bricklayers half the mortar used, and offsite CNC factories reduce material scrap by as much as 90%. Large-scale 3D printing can eliminate formwork and use recycled feedstock, drastically lowering concrete demand. Digital twins and BIM ensure that buildings operate efficiently and that materials are recovered at end-of-life, further amplifying savings. Parametric design, while less visible, enhances all fabrication methods by optimizing shapes for minimal material. In short, combining precise automation (robotics, 3D printing) with smart design (parametric models, twins) yields the greatest sustainability gains.

Is it true that sustainable digital fabrication can significantly lower construction costs?

It can, though savings vary by project. By reducing manual labor and material waste, many digital methods cut expenses. For instance, studies of 3D-printed homes report construction cost reductions on the order of 20–30% because machines work faster than crews and use exactly the needed material. Prefabrication also speeds schedules and minimizes rework, translating into fewer labor hours. However, new technologies often require upfront investment in equipment and training. Overall, when factored over time and scale, Sustainable Digital Fabrication often yields net cost benefits through efficiency and reduced waste, but results depend on the specific methods and materials used.

Conclusion

The construction industry can achieve low-impact, high-performance results by integrating these sustainable digital fabrication innovations. Large-scale additive manufacturing and prefab reduce raw material use and landfill waste; bio-based materials and parametric design lower embodied carbon; robotics and digital twins optimize precision and longevity; and computational deconstruction ensures materials keep circulating.

By embracing recycled and renewable inputs, automating for accuracy, and digitally tracking every component, builders can drastically cut carbon emissions and waste. In combination, these technologies point the way to truly green construction: every design is efficient, every material tracked, and every building eventually fed back into a circular economy. Sustainable Digital Fabrication is not a single tool but a holistic workflow, and together its innovations form a blueprint for a net-zero future in architecture and infrastructure.

Resources:

- UN Environment Programme. (2023). Building Materials and the Climate: Constructing A New Future.

- American Society of Civil Engineers. (2024). The future of construction? The case for 3D-printed, biobased materials.

- Urban Machine. (2023). The Machine: Robotics & AI Helping Reclaim Waste Wood.

For all the pictures: Freepik

Suggested article for reading:

4 Types of Fire Detection Systems and Where to Use Each One in 2025

Architecture University 2025: Top Programs Embracing Sustainability and Smart Tech

7 Real-World Applications of Concrete Sensors in Smart Construction Projects

The Future of Site Security: Emerging Trends in Alarm System Technology

Top 7 Modern Architecture Trends Shaping 2025: From Minimalism to Smart Homes

5 Essential Features to Look for in Site Security Alarm Systems