Exclusive Neuroject Article: With so many projects in progress, laser scanning in construction is becoming more and more common in the construction sector, and for good reason, it is the most precise and effective approach to evaluating existing infrastructure. But how does it function, and who gains from it? What instruments are easily accessible today? The primary goal of laser scanning in construction fundamentals is to provide you with a brief overview of the technology and its applications.

Every professional constructor needs to know about the benefits of laser scanning in construction. BIM has enhanced how experts in the architectural, engineering, and construction (AEC) industries cooperate, minimizing rework and aiding in eliminating unnecessary processes. It could be done by laser scanning that is accurate and accessible.

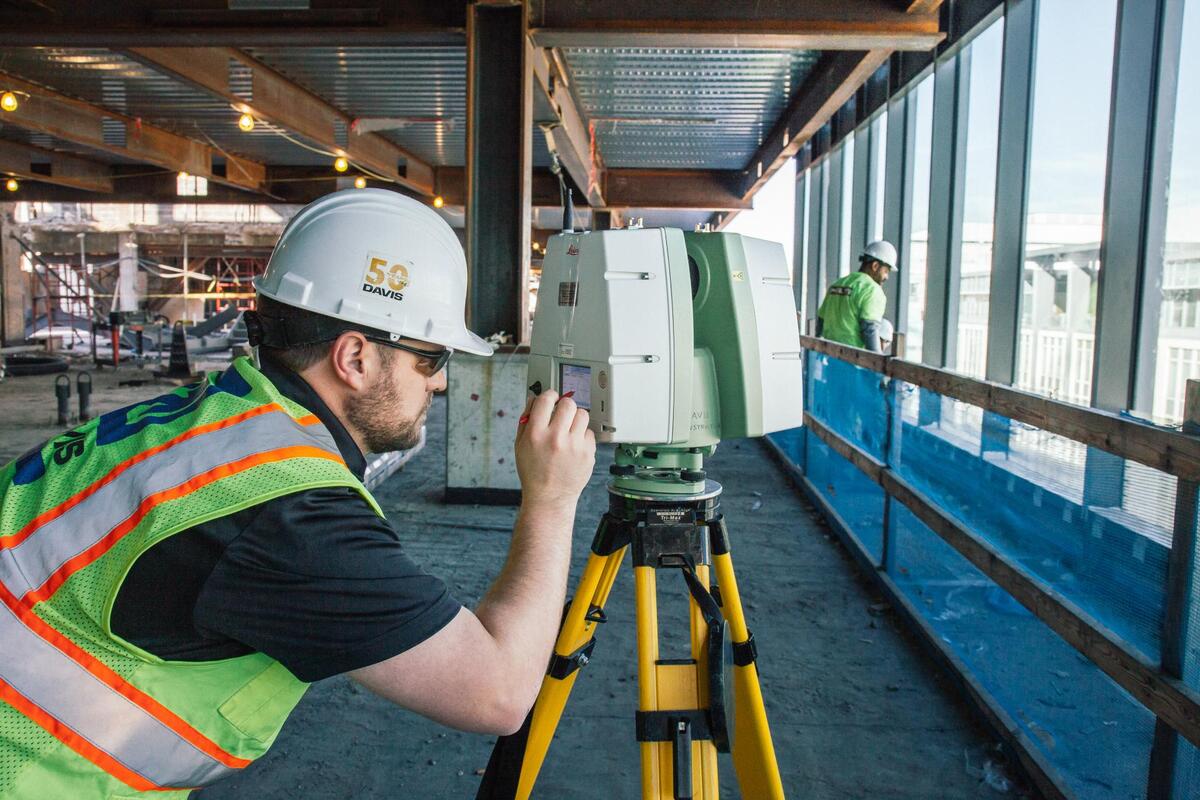

In the construction industry, laser scanning enables surveyors to offer as-built surveys, which reduces the need for costly rework by catching errors early on in the design-to-build process. Additionally, surveyors can play a crucial part in enhancing the planning, design, construction, management, and renovation processes for structures by utilizing laser scanning in construction. The basics of laser scanning in construction will be discussed in this article, along with a breakdown of the many techniques and equipment used to produce as-builts for use in architecture, engineering, and construction.

Table of Contents

3D Laser Scanning: How it Works?

The 3D laser scanner is a device that directs a laser beam toward the region being scanned using a rotating mirror and disperses the beam at an angle of 300° vertically and 360° horizontally. Then, bypassing anything in its path, the laser beam is reflected to the scanner. The distances to the elements that make up an area are computed along with their corresponding vertical and horizontal angles. A non-contact, non-destructive form of measurement is laser scanning.

Laser scanning is a technique for gathering surface data that quickly and precisely measures the distances between tightly spaced spots over an item. A point cloud survey or light detection and ranging (LIDAR, a combination of the words “light” and “radar”) are frequent names for the procedure. It is possible to utilize it to produce 3D images that can be transformed for use in 3D CAD modeling or building information modeling (BIM). High-speed lasers with an integrated camera that uses color coding are part of the instrumentation, which is mounted on a tripod. Usually, these devices can function up to 180 meters away and at speeds of up to 990,000 points per second.

The technique of 3D laser scanning is not new at all. The technology’s origins go back to the 1960s. It didn’t start being used for design and engineering purposes, nevertheless, until the 1990s. The technology’s adoption process was very similar to that of GPS or global positioning systems. Prior until recently, GPS was considered a luxury, but it is now present and used in millions of applications in numerous industries. Similar to how it did then, laser scanning has now permeated several businesses, including construction.

Suggested articles for reading: 5D BIM | BIM in Construction

Overview of Laser Scanning in Construction

In the construction industry, laser scanning, also known as Light Detection and Ranging (LiDAR) or High Definition Surveying (HDS), is the process of capturing, mapping and displaying the 3D geometry of current site infrastructure and existing plant conditions. This scan can then be uploaded, processed, and saved in the appropriate coordinates as a file that can be imported into modeling software, giving a highly accurate (usually accurate up to +/- 1/16″) picture of the facility that can be used in a variety of ways. This incredibly precise and thorough information is very useful for improving project designs for ease of construction and upkeep.

A network of points connected in a 3D coordinate system. We could go into great depth regarding point clouds and what they can do, but the most crucial thing to keep in mind is that they maintain an incredibly accurate digital record of an area or an object as it relates to a project.

In comparison to traditional survey measurement, laser scanning in construction has proven to be significantly faster, more precise, and less expensive. The stability of the instrument base and the process’s proximity to the object both affect how accurate it is. Sub-millimeter accuracy is achieved for close-range targets. A decent rule of thumb for accuracy in typical terrestrial survey work is + or – 2mm per 100m. Accuracy can reach + or – 50mm at greater distances than 2 km.

Suggested article for reading: Construction Technology

Why is 3D Laser Scanning in Construction Important?

When starting any design, renovation, or maintenance project, it’s essential to document the existing conditions. However, traditional surveying techniques are time-consuming, laborious, and only provide a limited amount of information, frequently resulting in site visits, cost overruns, and schedule delays These methods often only provide a limited amount of information, leading to site visits. Moreover, as a project progresses, different groups may require different amounts of information. This is where 3D laser scanning in construction comes in. It creates an accurate replica of the field, which can be easily accessed by the project team from their desktops. This removes any potential confusion that could arise from piecing together data gathered at different times by different individuals.

The Application of Laser Scanning in Construction

So, how does technology fit into modern construction? The technology has advanced significantly since it was first applied solely to industrial facility construction and maintenance. Today, it is used for constructing infrastructure and many other things. Here is a closer look at how laser scanning in construction is used during a project:

1. Design

In particular, laser scanning in construction is a starting point even before BIM when it comes to site design. Today, many experts use the scan-to-BIM design approach to gather thorough data and start and control the process early.

Architects construct their designs based on the building owners’ as-built plans. As-built data is occasionally inaccurate. Additionally, due to a lack of time and resources, contractors who conduct a site survey to confirm the circumstances of the site can miss details or overlook mistakes in the original design and construction plans. All of these design plan flaws become issues later in the construction workflow, leading to change orders, delays, and higher expenditures. The contractors verify as-built conditions and find design flaws during the pre-construction phase by utilizing 3D laser scanning in the construction procedure.

Suggested article for reading: Modern Architecture Buildings

2. Construction

When it comes to construction coordination, laser scanning in construction has a lot of advantages, particularly in preventing conflicts between various systems (such as HVAC, electrical, and plumbing). To aid in any distant cooperation, data can be shared between parties. Additionally, scanning isn’t just done at the start of a project; it may also be done at different subsequent stages to better document milestones, lessen the need for change orders, and delegate work to other tradespeople. Laser scanning in the building industry can also assist in identifying problems more quickly and documenting where mistakes were made.

Suggested article for reading: Construction HVAC

3. Retrofit and Renovations Operations

The great level of information that 3D building scanners acquire enables owners and facility managers to produce a permanent as-built record. In the end, this information can be useful for building maintenance, repairs, extensions, and even demolitions. More than half of the commercial buildings in the US were constructed before the 1980s, or 40 years ago, according to the US Energy Information Administration (EIA).

For comparison, IBM unveiled the MS-DOS computer in 1981. All drawings (if any were available) for these old structures were created manually, which presents a problem for architects who need to renovate them today. Another difficulty is that these structures might have undergone significant layout alterations. The ancient illustrations do not depict any of these internal modifications.

Laser Scanning in Construction Benefits

Deploying the technology on your upcoming project has a lot of advantages. Here are some of the most important justifications for laser scanning in construction:

- Enhances Efficiency & Quality: Laser scanning in construction is precise and enables construction teams to plan and detail projects to a whole new level on the job site.

- Cost Savings: Laser scanning in construction is quick, far quicker than traditional project mapping techniques. Compared to traditional methods, which can often take hours or even weeks to complete, scans can be finished in a matter of minutes. Additionally, the data scans that are produced enable teams to construct more intricate workflows. Since construction is a bottom-line industry, any cost savings that project teams can achieve only serve to boost project profitability. According to some estimates, employing the technology instead of traditional 2D scanning on a project can show up to 50% savings, with the fastest timeframe demonstrating the most profits.

- Streamlines Cooperation: 3D laser scanning in construction can facilitate collaboration and coordination on a job site, facilitating quicker and more accurate decision-making in general. Greater cooperation can support the final aim of developing a successful project by enhancing communication, improving connections among project team members, and more.

- Provides Immediate Information: Instantaneous information is available because of the ability to run scans and access them right away. This helps to streamline processes, increase productivity, and lessen rework.

- Reduces Manual Work: Manual labor can be tiresome and error-prone. Laser scanning in construction can both provide greater accuracy and aid in minimizing it. Additionally, scanning lessens the number of trips out to the site required for plan verification by other project participants, such as architects, engineers, surveyors, etc.

Suggested article for reading: Construction Cost

3D Laser Scanning in Construction Methods

There are various 3D laser scanning in construction today, depending on the projects. These include:

1. Stationary 3D Laser Scanners

Terrestrial laser scanners are another name for stationary 3D laser scanners. These instruments are used to record vertical structures like buildings, factories, and bridges. Because they are stationary, stationary scanners are renowned for giving the most precise measurements (point cloud data). These scanners cover the sphere around them by dispersing laser light in all directions.

A terrestrial scanner, which typically rests on a tripod, can finish a scan in 1.3 to 40 minutes, depending on the parameters and the information needed. These scans (setups) are typically depicted on a preliminary map displaying their intended location. Walls, pipelines, or obstacles that must be avoided should be taken into account. The goal is to be able to completely cover (scan) the area of interest from all directions.

Data processing is the process of connecting all the scan data (point clouds) based on common points (also referred to as targets) to create a single, consistent point cloud environment. The software used to process this data is unique to each manufacturer. In the final stage, CAD software such as Plant 3D, Revit, Microstation, etc. is used to import the single point cloud file that was created in step 2 and create a vector file. Consider it as the method required to create surfaces by drawing lines to link the points.

2. Handheld Laser Scanners

These devices are used to scan (measure) nearby smaller things like small structural components, mechanical components, etc. When a terrestrial scanner cannot enter due to an access restriction, handheld scanners can be handy. Additionally, rather than scanning 360 degrees around the object, they emit a laser straight at it.

3. Backpack 3D Laser Scanner

A scanning tool that is carried on the person’s back and operates while they move through the target region. Simultaneous Localization and Mapping (SLAM) technology is heavily used in this product. The majority of SLAM-based scanners include an RGB camera as well.

Before the person may begin exploring the area of interest, the backpack device, which is normally installed on the shoulders, needs to be calibrated. To assist the SLAM start, this calibration entails traversing a path and then crossing it from a different place. Calibration methods vary from manufacturer to manufacturer, but in general, this step is necessary before beginning a building scan.

In order to ensure that GPS corrections are made to the point cloud and matching points are found using SLAM, field data is post-processed. Normally, it takes one day to process one day’s worth of field data collection. The as-built drawings can be created by bringing the point-cloud data into CAD, Revit, Edgewise, or ArchiCAD software and converting it to vector files.

Applications of Laser Scanners in Construction

Laser scanners are used for several uses including but not limited to:

1. Survey

Laser scanners have revolutionized the surveying process in the construction industry. Surveyors use these devices to capture precise 3D data of the construction site, allowing for accurate measurements, site analysis, and topographic mapping. This technology significantly reduces the time and effort required for traditional surveying methods, making it a crucial tool for site preparation and design.

2. As-Built Modeling with Faro’s Revit Plugin

Faro’s As-Built Revit plugin is an essential tool for converting laser scanning data into accurate as-built models. Construction professionals use this plugin to streamline the process of creating detailed 3D models of existing structures. These models serve as a foundation for renovation and retrofitting projects, eliminating the need for time-consuming manual measurements and ensuring precision in design and construction.

3. Digital Twins

The concept of a digital twin involves creating a virtual replica of a physical building or structure. Laser scanning in construction plays a pivotal role in capturing the data necessary to create these digital twins. This technology allows construction teams to monitor the real-time status of a project, assess performance, and make data-driven decisions for improved project management and optimization.

4. Visual Tours with Matterport

Matterport’s 3D scanning technology enables the creation of immersive visual tours. In construction, this tool is used for showcasing real estate properties, design reviews, and project documentation. It provides stakeholders with a realistic and interactive experience of the site or building, enhancing communication and decision-making.

5. Screed Flatness with Faro’s Screed Flatness Tool

Faro’s Screed Flatness tool is a game-changer in the world of concrete construction. This technology assesses the flatness and levelness of concrete floors using laser scanning. It helps contractors ensure that the flatness of the floor meets required standards, reducing rework and improving the quality of the finished surface.

6. Wall and Facade Verticality

Laser scanning is utilized to assess the verticality of walls and facades during construction projects. It offers a precise method for ensuring that vertical elements are built accurately, meeting design specifications. Any deviations from the intended vertical alignment can be identified and corrected early in the construction process.

7. Restoration Projects with Photogrammetry

In historic preservation and restoration projects, laser scanning and photogrammetry are commonly used together. Photogrammetry complements laser scanning in construction by capturing detailed images and textures of architectural elements. The combined data allows for accurate restoration and replication of historical structures, preserving their original charm and design.

8. Comparison of Point Clouds and 3D Models

Laser scanning technology also plays a vital role in quality control. Construction professionals use it to compare point clouds generated from scans with 3D models created during the design phase. This comparison identifies any discrepancies between the planned design and the actual construction, facilitating early detection of issues and reducing costly rework.

9. Digital Handover and Maintenance

Laser scanning in construction is invaluable for creating detailed as-built models of completed structures. These models are essential for digital handover to building owners and facility managers. They serve as comprehensive reference guides for maintenance and facility management, enabling efficient operations and maintenance throughout the building’s lifecycle.

10. Augmented Reality for Site Insights

Augmented reality (AR) applications enable construction teams to superimpose laser scanning data onto the real world. This allows project stakeholders to visualize hidden elements behind walls and surfaces, enhancing on-site decision-making and improving safety by revealing potential hazards and obstacles. AR applications complement laser scanning in construction, providing a powerful tool for construction teams.

These various uses of laser scanners and associated tools have transformed the construction industry, enhancing efficiency, accuracy, and collaboration throughout the project lifecycle.

Devices used for Laser Scanning

There are various devices used for creating point clouds through laser scanning and photogrammetry. These devices are crucial components of the technology landscape in the fields of surveying, construction, and 3D modeling. Here’s a brief overview of some of the devices you mentioned:

1. Faro Laser Scanners

Faro is a well-known manufacturer of 3D laser scanning equipment. Their laser scanners, such as the Faro Focus series, are commonly used for capturing precise 3D point cloud data in various industries, including architecture, engineering, and construction.

2. Matterport Devices

Matterport specializes in 3D imaging technology for creating digital twins of physical spaces. Their devices, like the Matterport Pro2 and Pro3D, use photogrammetry to generate 3D models and point clouds, making them valuable tools for real estate, interior design, and virtual tours.

3. DJI Scanners

DJI, primarily known for drones, has also ventured into LiDAR scanning technology. Their LiDAR scanners, such as the DJI Zenmuse L1, are mounted on drones and are used for topographic mapping, construction site monitoring, and more.

4. Lidar Scanners (Various Generations)

LiDAR technology has been evolving rapidly, with various manufacturers producing LiDAR scanners for different applications. Some of the key players include Velodyne, Quanergy, and Innoviz. LiDAR technology is essential for autonomous vehicles, environmental monitoring, and advanced surveying.

These devices have a broad range of applications, from creating detailed 3D models for architectural design to capturing topographic data for land surveying. Users can choose the most appropriate device based on factors like accuracy, range, and portability, depending on their specific needs.

Trending Topics in Laser Scanning in Construction

there are several trending topics and emerging technologies related to laser scanning in construction. Here are a few notable trends and topics you can consider incorporating into your paper:

- Scan-to-BIM (Building Information Modeling): Scan-to-BIM is a critical trend where laser scanning technology is used to create accurate 3D models of existing structures. These models can be integrated into BIM software to facilitate renovation, retrofitting, and maintenance projects. Highlight the benefits of Scan2BIM in reducing errors and improving project efficiency.

- Mobile Laser Scanning in Construction: Mobile laser scanning systems, often mounted on vehicles, are becoming increasingly popular. They can rapidly capture detailed 3D data of large areas, such as roadways and urban environments. Discuss how this technology is being used for infrastructure projects and city planning.

- Indoor Mapping and Navigation: Laser scanning is being used for indoor mapping and navigation in facilities like airports, warehouses, and large public spaces. This technology enhances safety and efficiency by providing real-time information on people’s movements and asset locations.

- Laser Scanning and Augmented Reality (AR): The integration of laser scanning with AR is another exciting trend. It enables construction professionals to overlay 3D point cloud data onto the real-world environment, allowing for better visualization, project monitoring, and quality control.

- Environmental Monitoring with Lidar: Lidar technology is increasingly used for environmental monitoring, such as forest management, flood prediction, and coastal erosion assessment. Discuss the potential applications of laser scanning in these areas and its contribution to sustainability in construction.

- Drone-Based Lidar Scanning: Combining drone technology with Lidar scanning offers rapid and cost-effective data collection for construction and surveying. Explore how this technology is revolutionizing aerial data capture and site analysis.

- AI and Machine Learning in Data Analysis: Laser scanning in construction generates vast amounts of data, and AI and machine learning are being used to automate data processing and extraction of actionable insights. Discuss the role of AI in point cloud analysis and data management.

- LiDAR for Autonomous Construction Equipment: LiDAR sensors are essential for autonomous construction equipment, enhancing safety and efficiency on construction sites. Highlight how these sensors are enabling the development of autonomous construction machinery.

- Virtual Reality (VR) for Project Planning: Laser scanning data can be used in VR environments for immersive project planning and design reviews. Explain how VR technology is changing the way stakeholders collaborate and make decisions in construction projects.

- Sustainability and Energy Efficiency: Laser scanning in construction can help assess and improve the energy efficiency of existing buildings. Discuss how it aids in retrofitting and optimizing structures for sustainability.

Laser Scanning in Construction Challenges

Every technology has advantages and disadvantages, and while laser scanning in construction has many advantages, it also has certain disadvantages. Implementing laser scanning in construction has considerable benefits, but it also has certain risks. Here are some examples of them:

- The Expensive Operation: The cost of implementing the technology is quite high, especially if you want it done well, even though scanning can assist in reducing project expenses overall. Many businesses may be put off by this large up-front investment.

- Scope: Scanners can assist in producing extremely precise site plans, but for the greatest results, personnel still need to be familiar with the region.

- Practice is Required: Construction staff must receive rigorous training on how to use the device effectively, just like with any other technology. There can be a skills gap in your firm when it comes to this, and training could add to the high upfront expenditures we indicated above.

The Best Practices for 3D Laser Scanning in Construction

Every stakeholder in the life of a construction project can benefit from 3D laser scanning, but only if it is done properly. It could go wrong if you don’t take the appropriate safety measures to guarantee success. You must use technology properly if you want to maximize benefits and minimize drawbacks. We provide the following advice and best practices to help you get going:

1. Launch Early 3D Laser Scanning in Construction

You can get knowledge through laser scanning in construction throughout a project. As a result, you should incorporate it into your projects as soon as you can. You’ll have the best and most accurate understanding of the project and job site if you start early.

2. Use Laser Scanning in Construction with Other Technologies

A single tool in your toolbox, laser scanning in construction is not a panacea. Don’t overlook the other tools at your disposal. Using several surveying methods for one project is not a thing to be ashamed of. Your CAD and BIM models can both be improved by laser scanning in construction.

Making a plan for when and how you will employ laser scanning in your projects will assist in reducing confusion and wasteful spending of time and resources. Technology can be used to improve documentation procedures, assess current circumstances and project progress, and facilitate on-site task coordination for projects.

Suggested article for reading: Building Technology

3. Collect More Data as You Think You Need

4. Establish a Dedicated Laser Scanning Crew

The learning curve for 3D laser scanning in construction is considerable. Even if you could teach every employee how to use it, you’ll discover that creating a scanning crew will be more affordable. A specialized scanning crew will have the time and training necessary to comprehend the technology’s operation and limitations in its entirety. In order to minimize any potential production pauses, the group can potentially collaborate with other project teams. Your business will benefit from utilizing the technology to its fullest potential at the lowest possible cost.

5. Understand and Know the Construction Space Limitation Before You Scan

Laser scanning in construction can speed up the process of investigating and surveying a job site, but it is time-consuming and expensive upfront. Additionally, the tools need ample room to operate properly. Use it only when and when you need it to help you, and you can lessen some of the limits.

6. Knowledge of the Project Scope

Due to the versatility of laser scanning in construction, there may be more uses you had not previously thought about. In addition to modeling and surveying a site, the technology may be used to direct workers through a project to make sure everyone is on the same page.

The Future of Laser Scanning in Construction

Laser scanning in construction is now being used in new projects and to support BIM. A record of information on the structural elements, HVAC, pipelines, and rebar throughout the structure may be created with astounding accuracy if a contractor scans all construction components in real-time as they are placed. As the data can be compared to the actual design to make sure that everything was installed correctly, this serves as a useful reference manual.

In addition, drones and artificial intelligence (AI) are new equipment with laser scanning capabilities that are used for data collection to increase construction productivity. To assess efficiency and quality at the job site, these drones and robots are fitted with laser scanners. By eliminating the requirement for staff to physically be present on-site to conduct laser scans, AI-powered data collecting saves time. Drone use reduces wait times by making it simpler to assess a job site’s efficiency and quality from above.

Suggested articles for reading: Future of Construction | AI in Construction

Conclusion

The advancement of laser scanning in construction has increased design accuracy, facilitated teamwork, and cut down on survey time. For engineering analysis, 3D laser scanning in construction is a technique used to accurately duplicate current conditions. Documenting as-builts for vertical constructions will become standard practice. Various tools are available for 3D laser scanning, and the best one to employ will depend on the project’s needs. The quality and efficiency of the project will improve right away, and the project teams will save money in the long run.

The usage of equipment in laser scanning in construction by contractors should be sought out whenever possible by developers and building owners. Considering the future of the construction industry, using 3D data collected at this scale for integrated design-build projects makes sense. Due to their efficiency, BIM and big data will keep spreading, eventually embracing the whole architecture, engineering, and construction sectors. Why not use millions of precise data points to virtually map your next project for future use?

Resources:

Designing Buildings | Centerline Design | Builder Space | Hexagon Geo Systems | HM-EC | Autodesk | Reality IMT | DJM | NOAR | VIP Structures

For all the pictures: Freepik | MODS Blog | AEC Magazine | Red Laser Scanning | UK Construction Media | DAVIS Construction | PBC Today