Exclusive Neuroject Article: A digital twin is a virtual representation of a physical object. It spans the item’s lifecycle and simulates and monitors processes using real-time data sent by sensors on the object. Because of the relationship between the digital and physical worlds, global industries have undergone considerable technological transformation. Digital twin technology has been instrumental in accelerating this convergence.

Companies or organizations can use this technology to create digital copies of their products, assets, or processes to improve performance and upkeep. This technique, for example, has been used in the automobile sector to produce digital copies of cars. Manufacturing companies have also utilized it to recreate physical manufacturing processes. Reviewing digital twin examples can help us understand and utilize this technology.

Without a doubt, building a digital twin would be pointless if there were no practical reasons to do so. It has already been said that one cannot create a perfect machine in a single attempt and that testing on physical things requires a lot of money and effort. In addition, digital twins and IoT (Internet of Things) combined with artificial intelligence assist us in analyzing data and monitoring systems to investigate and solve these difficulties.

Whereas changing a physical product can be time-consuming, a digital counterpart can be quickly altered to illustrate changes and conduct simulations. In this article, we review the 13 best digital twin examples to understand this topic.

Table of Contents

Definition of Digital Twins

Digital twins are virtual representations or digital replicas of physical objects, processes, systems, or entities. They’re created using real-time data from sensors, IoT devices, and other sources to simulate the characteristics, behaviors, and functionalities of their physical counterparts.

These digital replicas are more than just static models. They continuously gather data from the physical world, enabling them to mimic real-world changes and conditions in real-time or near-real time. This data-driven simulation allows for monitoring, analysis, and optimization of the physical objects or systems they represent.

Digital twins can be applied across various domains, including manufacturing, healthcare, smart cities, aerospace, and more. They serve as powerful tools for predictive analysis, performance monitoring, decision-making, and fostering innovation by allowing experimentation and scenario testing without impacting the actual physical entities.

Benefits of Digital Twins

Digital twins offer a multitude of benefits across various industries and sectors due to their ability to bridge the physical and digital worlds. Some key advantages include:

- Predictive Maintenance: They enable predictive analysis by continuously monitoring and analyzing real-time data from physical assets. This helps in identifying potential issues before they occur, reducing downtime and maintenance costs.

- Improved Efficiency: Optimization of operations and processes through simulation and analysis of data leads to increased efficiency in manufacturing, supply chains, and other complex systems.

- Real-time Monitoring and Control: Digital twins provide real-time insights into the performance and behavior of physical assets, allowing for immediate adjustments or interventions when necessary.

- Reduced Risks and Costs: By simulating scenarios and conducting tests in the virtual environment, organizations can mitigate risks and identify cost-effective solutions before implementing changes in the physical world.

- Innovation and Product Development: They facilitate innovation by allowing for experimentation and testing without impacting physical assets. This accelerates the development of new products or improvements to existing ones.

- Optimized Resource Management: Digital twins help in optimizing the use of resources such as energy, materials, and time by analyzing data and suggesting efficient strategies.

- Enhanced Decision-making: They provide valuable insights and data-driven information that aid in making informed decisions, whether in design, operations, or future planning.

- Personalized Experiences: In sectors like healthcare, digital twins can model individual patients to enable personalized treatment plans and better healthcare outcomes.

- Sustainability: By optimizing processes and resource usage, digital twins contribute to more sustainable practices in industries, reducing waste and environmental impact.

- Remote Operations and Monitoring: Especially in the era of remote work and automation, digital twins enable remote monitoring and control of assets and processes, allowing for efficient management from anywhere in the world.

These benefits collectively make digital twins a valuable technology across industries, contributing to increased efficiency, innovation, and improved decision-making.

Suggested article to read: Digital Twin Technology in Construction & Building

Digital Twin Examples

Digital twins, virtual replicas of physical assets or systems, have revolutionized industries by bridging the gap between the physical and digital realms. Here, we explore 13 compelling digital twin examples showcasing the versatility and impact of its technology across diverse sectors.

1. Manufacturing: Smart Factory Optimization

In the bustling realm of automobile manufacturing, the integration of digital twins has revolutionized the traditional production paradigm as our first digital twin examples. Within a prominent manufacturing plant, the implementation of digital twins mirrors the entire production line, catalyzing a multifaceted approach toward enhancing operational efficiency and prognosticating maintenance requirements.

Real-time Predictive Maintenance

At the crux of this innovation lies the capability for real-time monitoring of machinery performance. Digital twins meticulously observe and analyze the intricate metrics of each machinery component, foreseeing potential malfunctions or wear-and-tear before they actualize. This proactive approach allows for preemptive maintenance, reducing unforeseen downtime and ensuring continuous production flow.

Efficiency-Driven Production Simulations

Beyond mere monitoring, these digital replicas perform an intricate dance of simulations, orchestrating diverse production scenarios. By meticulously modeling various operational strategies, they discern the most optimized pathways, fine-tuning workflows, and orchestrating an ecosystem of streamlined efficiency. These simulations act as a crucible for innovation, minimizing downtime and resource wastage while bolstering productivity to its zenith.

These digital twin examples, amalgamation of real-time monitoring and simulated foresight have not just streamlined operations within the automobile manufacturing landscape but have become the vanguard of smart factory optimization, setting new benchmarks for efficiency and reliability in industrial production.

2. Healthcare: Patient-Specific Treatment

Within the intricate corridors of healthcare, the advent of digital twins has ushered in a new era of precision and personalized care. Hospitals now harness the power of digital replicas to sculpt patient-specific models, fostering bespoke treatment plans tailored to individual needs.

Simulated Anatomy for Surgical Precision

At the heart of this medical innovation lies the meticulous simulation of individual anatomy. Digital twins meticulously recreate the nuanced intricacies of a patient’s physiology, offering surgeons a virtual canvas to rehearse complex procedures with unparalleled precision. These simulations act as a sanctuary for experimentation, empowering medical professionals to strategize and execute intricate surgeries with heightened accuracy and confidence.

Real-time Vital Sign Monitoring for Enhanced Care

Beyond the realms of surgical precision, these digital counterparts stand vigil, continuously monitoring vital signs in real-time. This constant surveillance serves as an omnipresent guardian, swiftly alerting medical personnel to any deviations or anomalies. Prompt interventions fueled by this instantaneous data ensure timely and tailored care, significantly enhancing patient outcomes and well-being.

The fusion of simulated anatomical accuracy and real-time vigilance embodies a paradigm shift in healthcare, fostering a landscape where each treatment plan is a bespoke masterpiece, sculpted with precision and compassion to cater to the unique needs of every patient.

3. Aerospace: Aircraft Performance Analysis

In the realm of aerospace innovation, digital twins examples have emerged as stalwart companions, intricately mirroring the complex systems of aircraft. These digital counterparts unfurl a tapestry of possibilities, enabling meticulous analysis and prognostication within the domain of aircraft performance.

Continuous Engine Health Monitoring

At the core of this aerospace revolution lies the continuous vigilance over engine health and efficiency. Digital twins stand as vigilant sentinels, monitoring the intricate machinations of engines with unwavering precision. By analyzing myriad data points, they predict potential part failures well before they transpire. This foresight empowers aviation engineers to schedule preemptive maintenance, ensuring the unbroken flight operations of these aerial marvels.

Simulated Flight Conditions for Optimization

Beyond the confines of mere monitoring, these digital replicas unfurl their wings into the realm of simulation. They orchestrate virtual flight scenarios, mimicking a myriad of conditions, from turbulence to altitude changes. This simulated journey acts as a canvas for engineers, facilitating intricate adjustments to enhance safety measures and optimize fuel efficiency. Through these simulated flights, improvements are iteratively tested and fine-tuned, ensuring aircraft operate at the pinnacle of performance.

This fusion of continuous vigilance and simulated innovation embodies the essence of aerospace advancement. This Digital twin examples not only predict failures but act as catalysts for continuous improvements, fostering aeronautical marvels that soar the skies with enhanced safety and efficiency.

4. Smart Cities: Traffic Management

In the bustling heartbeats of metropolitan areas, digital twins stand as pioneers in revolutionizing the intricate choreography of urban mobility. Their integration into city systems has heralded a new dawn of efficiency in traffic management and urban planning.

Real-Time Traffic Flow Optimization

At the nexus of this urban transformation lies the orchestration of real-time traffic flow analysis. Digital twins act as omnipresent observers, meticulously studying the pulsating rhythm of vehicular movement. By processing copious streams of data, they decipher patterns and intricacies, allowing for the optimization of signal timings. This orchestrated dance of synchronized signals alleviates congestion hotspots, ensuring smoother vehicular movement and shorter travel times.

Simulated Urban Development for Informed Decisions

Beyond the purview of immediate traffic concerns, these digital replicas extend their reach into the realm of urban development. City planners harness their power to simulate various developmental projects, envisioning the impact on traffic flow and urban dynamics. These simulations act as a crystal ball, empowering decision-makers with insights into the ramifications of each urban design choice. Informed decisions pave the way for sustainable and harmonious urban landscapes that cater to the evolving needs of inhabitants.

This convergence of real-time analysis and simulated foresight encapsulates the essence of urban transformation. Digital twins not only alleviate immediate traffic woes but act as catalysts for informed urban planning, laying the groundwork for interconnected and efficiently managed smart cities of tomorrow.

5. Energy Sector: Wind Farm Optimization

Within the boundless stretches where wind turbines dance in harmony with nature, digital twin examples have emerged as guiding beacons, orchestrating a symphony of efficiency and sustainability in the energy sector.

Turbine Performance Monitoring for Enhanced Uptime

At the heart of this renewable energy revolution lies the vigilant surveillance of turbine performance. Digital twins stand as meticulous custodians, monitoring each turbine’s health and functionality in real-time. By scrutinizing a myriad of performance metrics, they forecast potential maintenance needs well in advance. This predictive prowess allows for strategic scheduling of maintenance, minimizing downtime, and ensuring the continuous harnessing of wind energy.

Simulated Wind Patterns for Optimal Efficiency

Beyond mere monitoring, these digital replicas unfurl their wings into the realm of simulation. They meticulously model and simulate diverse wind patterns, akin to an ethereal dance of gusts and breezes. These simulations act as a tapestry for engineers, facilitating optimal turbine placement to harness the most potent winds. By predicting wind patterns, energy output can be estimated and optimized, ensuring maximum utilization of nature’s energy.

This fusion of vigilant monitoring and simulated foresight epitomizes the winds of change within the energy sector. Digital twin examples not only optimize turbine performance but serve as architects of sustainable energy production, harnessing the power of the wind to propel us towards a greener and more efficient future.

6. Retail: Personalized Shopping Experience

In the bustling aisles and digital storefronts of retail, digital twins have emerged as pioneers reshaping the shopping landscape. Their integration into retail spaces transcends mere transactions, fostering a personalized and seamless shopping experience for every customer.

Customer Behavior Analysis for Tailored Recommendations

At the heart of this retail revolution lies the intricate analysis of customer behavior. Digital twins act as astute observers, meticulously tracing the digital footprints of shoppers. By assimilating and analyzing vast troves of data, they unveil patterns and preferences, offering retailers a kaleidoscope of each shopper’s preferences. This analysis serves as the bedrock for tailored product recommendations, enhancing the customer journey and fostering a sense of personalized engagement.

Store Layout Simulations for Optimized Shopping Environment

Beyond the digital realm, these replicas transcend into the physical space of stores. Retailers harness their power to simulate and iterate store layouts, akin to an architect sculpting spaces for optimal experiences. These simulations reimagine store layouts, facilitating improved traffic flow and enhanced inventory management. By fine-tuning the arrangement of products and spaces, retailers craft an environment that not only entices but also streamlines the shopping journey, culminating in enhanced customer satisfaction.

This amalgamation of data-driven insights and physical space optimization epitomizes the retail transformation. Digital twins not only cater to individual preferences but also serve as maestros orchestrating the harmony between digital analysis and physical retail environments, redefining the art of personalized shopping experiences.

7. Automotive: Vehicle Prototyping and Testing

In the realm of automotive engineering, digital twin examples have become indispensable partners, offering a virtual canvas for innovation and safety refinement before vehicles hit the road.

Performance Simulation for Design Enhancement

At the core of this automotive revolution lies the ability to virtually simulate vehicle performance under diverse conditions. Digital twins meticulously recreate the dynamic interplay between vehicle components, scrutinizing their behavior in varying environments. By subjecting these digital replicas to a myriad of scenarios, from extreme weather conditions to challenging terrains, engineers extract invaluable insights. These simulations serve as a playground for iterative improvements, refining vehicle designs for optimal performance, durability, and efficiency long before the prototype hits the road.

Crash Scenario Analysis for Advanced Safety Measures

Beyond performance evaluations, digital twin examples extend their reach into the domain of safety. They orchestrate intricate crash simulations, analyzing the vehicle’s response under diverse collision scenarios. By meticulously assessing the impact on different components, these simulations inform the design of safety measures that mitigate potential risks. Engineers refine safety systems, from airbag deployment to structural integrity, fostering vehicles that prioritize passenger safety.

This fusion of performance scrutiny and safety refinement epitomizes automotive innovation. Digital twins not only refine vehicle performance but also act as guardians, ensuring that safety measures are rigorously tested and optimized, paving the way for safer and more reliable vehicles on the roads.

8. Agriculture: Crop Management

In the vast expanse of agricultural landscapes, digital twin examples have emerged as indispensable tools, guiding farmers toward efficient and optimized crop cultivation techniques.

Precision Monitoring for Soil and Weather Conditions

At the heart of this agricultural revolution lies the vigilant monitoring of crucial variables. Digital twin examples serve as meticulous observers, assimilating data on soil compositions and weather patterns with precision. By comprehensively analyzing these vital factors, they offer insights that guide precise irrigation and fertilization strategies. This data-driven approach optimizes resource utilization, ensuring that crops receive the exact nutrients and water they require for robust growth.

Simulation for Informed Planting Strategies

Beyond monitoring, these digital replicas transcend into predictive simulations. They model diverse growth scenarios, factoring in soil conditions, weather fluctuations, and planting strategies. These simulations act as a crystal ball for farmers, predicting crop yields under varying conditions. Armed with this foresight, farmers fine-tune planting strategies, optimizing crop types and planting schedules for maximal yields and resource efficiency.

This amalgamation of data-driven precision and predictive simulations encapsulates agricultural advancement. Digital twins not only assist in precise resource allocation but also empower farmers with foresight, enabling informed decisions that maximize crop yields while minimizing environmental impact.

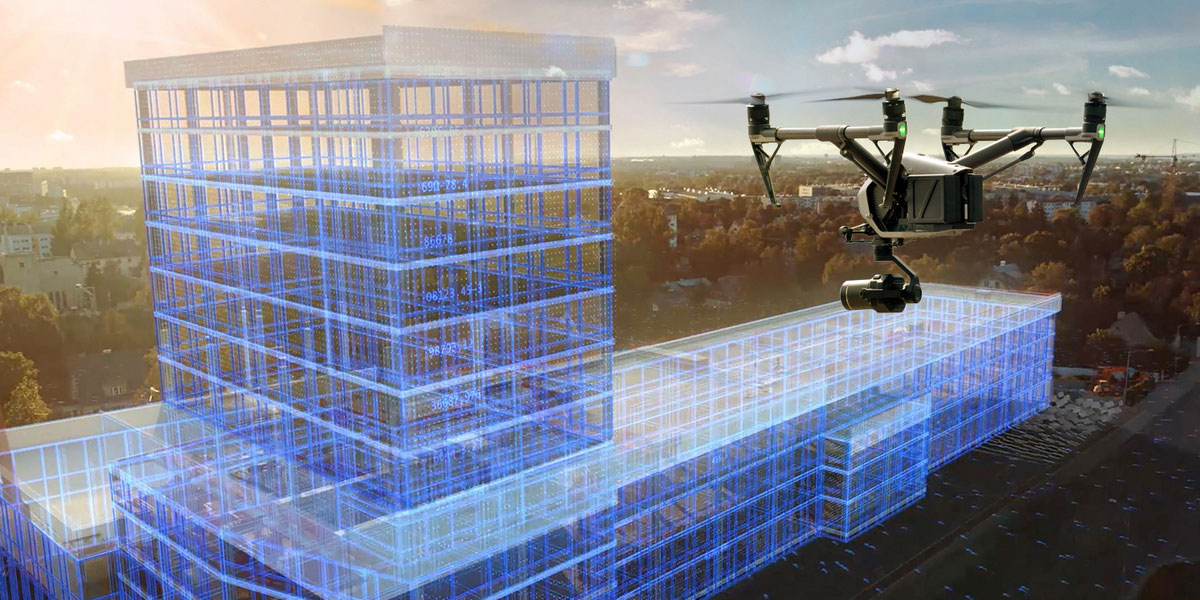

9. Construction: Building Design and Monitoring

Within the dynamic domain of construction, digital twin examples have emerged as transformative tools, redefining the blueprint for architectural innovation and construction efficiency.

Structural Integrity Simulations for Safety Assurance

At the core of this revolution lies the integration of digital twins into structural design. These replicas meticulously simulate the intricacies of construction materials and design layouts. By subjecting these digital models to rigorous simulations, engineers assess structural integrity and safety predictions. These simulations act as virtual stress tests, identifying potential weaknesses or hazards. Insights garnered from these simulations aid in refining designs and preemptively addressing safety concerns, ensuring buildings are not just aesthetically pleasing but also structurally sound.

Real-Time Monitoring for Agile Construction Management

Beyond the blueprint phase, digital twins extend their utility to real-time construction monitoring. By integrating with on-site sensors and data streams, these digital counterparts vigilantly track progress. Real-time monitoring enables project managers to assess construction milestones, detect deviations, and identify potential delays promptly. Timely interventions based on this monitoring not only ensure adherence to schedules but also result in cost savings by averting potential setbacks.

This amalgamation of predictive simulations and real-time monitoring epitomizes innovation within construction. Digital twins not only ensure structural integrity but also serve as vigilant overseers, fostering a landscape of agile construction management and architectural excellence.

10. Oil and Gas: Asset Performance

In the realm of oil and gas, digital twins have emerged as indispensable assets, orchestrating a symphony of efficiency and safety across vast and complex infrastructures.

Vigilant Monitoring for Early Failure Detection

At the core of this transformation lies the vigilant gaze cast upon pipelines and equipment. Digital twins act as vigilant custodians, continuously monitoring these critical assets. By scrutinizing operational parameters and analyzing data streams in real-time, they detect subtle anomalies that signal potential failures. This proactive approach allows for early interventions, minimizing the risk of disruptions or accidents and ensuring the seamless flow of operations.

Simulation for Enhanced Safety and Efficiency

Beyond monitoring, these digital replicas extend their utility to the simulation of drilling operations. They meticulously model and simulate drilling scenarios, considering a myriad of variables including geological conditions, equipment performance, and safety protocols. These simulations act as a testing ground, allowing engineers to refine operational strategies to enhance safety measures and operational efficiency. Through these simulations, risks are mitigated, and operational excellence is pursued without compromising safety standards.

This amalgamation of vigilant monitoring and simulated foresight epitomizes innovation within the oil and gas sector. Digital twins not only ensure the reliability of critical assets but also act as catalysts for advancing safety protocols and operational efficiencies, fostering a landscape of resilient and efficient energy production.

11. Maritime: Ship Performance Analysis

In the vast expanse of maritime operations, digital twins have emerged as navigational allies, charting a course toward optimized ship performance and safer voyages.

Real-Time Monitoring for Efficient Operations

At the heart of this maritime evolution lies the continuous vigilance over vessel conditions. Digital twins serve as diligent overseers, perpetually monitoring a ship’s myriad components in real-time. By scrutinizing operational data and performance metrics, they optimize fuel efficiency and predict maintenance needs. This proactive approach ensures vessels operate at peak performance while minimizing fuel consumption and maintenance-related downtime.

Simulation for Improved Safety and Navigation

Beyond immediate monitoring, these digital replicas extend their utility to simulated voyages. They meticulously simulate diverse navigation scenarios, considering factors such as weather conditions, currents, and vessel capabilities. These simulations act as virtual test runs, allowing for the refinement of route planning and safety protocols. Through these simulations, safer and more efficient navigation paths are charted, minimizing risks and enhancing the overall safety of maritime operations.

This fusion of real-time oversight and simulated voyages epitomizes the evolution of maritime operations. Digital twins not only optimize vessel performance but also act as navigational guides, ensuring safer and more efficient voyages across the seas.

12. Education: Virtual Learning Environments

Within the realm of education, digital twins have emerged as pioneers, reshaping the traditional classroom into a dynamic and immersive learning environment.

Simulated Laboratories for Remote Hands-On Learning

At the core of this transformation lies the creation of virtual laboratories. Digital twins replicate real-world lab settings, enabling students to conduct experiments and simulations remotely. These digital replicas foster hands-on learning experiences where students can manipulate variables, perform experiments, and observe outcomes in a controlled virtual environment. Through these simulated laboratories, educational institutions transcend geographical barriers, ensuring access to practical learning experiences regardless of physical location.

Interactive Models for Complex Subjects

Beyond laboratories, digital twins extend their utility to the realm of complex subjects like physics or biology. They create interactive models that visualize abstract concepts, making them more tangible and easier to comprehend. These interactive models serve as educational aids, allowing students to interact with complex theories, conduct virtual experiments, and gain a deeper understanding through visualization and engagement.

This fusion of simulated hands-on experiences and interactive models exemplifies the transformative power of digital twins in education. They not only facilitate practical learning in remote settings but also enhance understanding and engagement, shaping a future where education transcends traditional boundaries to offer immersive and accessible learning experiences for all.

13. Sports: Athlete Performance Tracking

In the realm of sports, digital twins have emerged as game-changing allies, revolutionizing athlete training and performance analysis.

Biometric Monitoring for Personalized Training

At the core of this athletic evolution lies the meticulous monitoring of biometric data. Digital twins act as personalized trackers, continuously analyzing an athlete’s biometrics – from heart rate to muscle activity. This wealth of data serves as the foundation for tailored training programs. By synthesizing this information, coaches craft personalized regimens that optimize performance and prevent injuries. These programs cater to individual needs, maximizing training efficiency while mitigating the risk of overexertion or strain.

Simulation for Strategic Development

Beyond individual performance, digital twins extend their utility to simulated game scenarios. They replicate match conditions and game strategies, offering a virtual platform for strategic development. Athletes immerse themselves in these simulations, honing their decision-making skills and refining game tactics without the physical strain of real matches. Through these simulations, teams strategize, adapt, and elevate their performance, fostering a competitive edge on the field.

This fusion of personalized monitoring and simulated training epitomizes innovation within sports. Digital twins not only optimize individual performance but also serve as strategic enablers, empowering athletes and teams to refine their skills and strategies in a safe and controlled environment, shaping the future of athletic excellence.

Conclusion: Pioneering a New Era of Innovation and Efficiency through Digital Twins

Digital twins, the symbiotic marriage of virtual replicas and real-time data, stand as beacons of transformation across industries, orchestrating a convergence between physical reality and the digital realm. These digital counterparts have revolutionized how we perceive, interact with, and optimize our physical world.

At its core, a digital twin transcends mere simulation; it embodies a dynamic entity perpetually mirroring and evolving alongside its physical counterpart. This dynamicity empowers industries to predict, analyze, and optimize with unparalleled precision, shaping a landscape where innovation, efficiency, and decision-making converge seamlessly.

The applications of digital twins resonate across every facet of modern existence. In manufacturing, they choreograph smart factories, optimizing workflows with a precision that minimizes downtime and maximizes efficiency. Healthcare harnesses its power to sculpt personalized treatment plans, enhancing surgical precision and patient care. Transportation sees safer skies and smoother seas, courtesy of predictive simulations fine-tuning performance and navigation strategies.

Their influence extends even into education, where virtual laboratories and interactive models redefine the pedagogical landscape, offering hands-on experiences and enhancing comprehension. Athletes leverage digital twins for personalized training regimens and strategic development, fostering a new dimension of athletic excellence.

Yet, their potential remains boundless. Digital twins are not just tools; they are catalysts for a future where innovation is limitless and decision-making is fortified by data-driven insights. As technology advances, their role will continue to evolve, transcending boundaries and shaping an interconnected world where efficiency, sustainability, and innovation converge harmoniously.

In conclusion, digital twins stand as sentinels of progress, ushering in an era where the physical and digital realms coalesce, propelling industries, societies, and humanity toward unparalleled heights of efficiency, innovation, and interconnectedness.

More articles to read:

Nanotechnology in Construction Industry

7 Important Building Technology

Resources:

Toobler | PALAMIR | Challenge Advisory | Forbes | SAP | Ericsson | SL Controls | PTC

For all the pictures: Freepik | vodafone | Zameen | The Fifth State