Exclusive Neuroject Article: The construction industry is evolving at a rapid pace, driven by technological advancements, changing market dynamics, and growing environmental concerns. As we step into 2024, it’s crucial for construction professionals to stay informed about the latest trends that are shaping the industry.

From sustainable construction practices to the adoption of advanced technologies, these trends are set to transform the way we design, build, and operate structures. In this article, we will explore the top 21 construction industry trends of 2024, providing insights into the exciting developments that will shape the future of construction.

Table of Contents

An Introduction to Construction Industry Trends

Buildings and infrastructure that serve as the foundation of contemporary civilization are provided by the construction sector, which is a crucial pillar of worldwide economic development. The construction industry trends are changing along with technology, social dynamics, and environmental concerns. For stakeholders, including developers, contractors, and legislators, understanding the most recent developments in the construction sector is essential to staying ahead in a constantly shifting environment.

The paradigm in the construction business has changed recently, with new approaches and cutting-edge technologies changing established processes. These construction industry trends are being pushed by the demands of a digitally-driven society, rising urbanization, and a growing need for ecologically friendly and sustainable solutions.

The global epidemic has also had a big impact on construction industry trends, changing how people think about health and safety, how they operate remotely, and how quickly they adopt new technology.

This article seeks to offer a perceptive assessment of the current construction industry trends. We will look into the major factors influencing the sector’s trajectory by examining numerous sources and studies. It is crucial to understand that construction industry trends are dynamic and responsive to continuous changes in the global scene rather than static.

Industry experts can more effectively plan their enterprises, use cutting-edge technologies, and match their initiatives with more general societal and environmental aims by thoroughly examining these trends. Those involved in the construction value chain must work together to address the opportunities and difficulties these changes provide.

It is crucial to keep in mind both the potential advantages and difficulties these developments may provide as we examine the changing environment of the construction sector. Stakeholders may help the construction industry trends grow and flourish by making educated decisions and staying up to date on these revolutionary advances.

1. The Rise of Zero Energy Buildings in Green Construction

The term “ZEB” is intended to generally indicate a category of buildings with very high energy performance in the operational phase, characterized by a very low or almost zero annual energy requirement, entirely or very significantly covered by renewable energy, produced on-site or nearby in the sector of construction industry trends.

The energy performance of a building is usually determined based on the amount of annual primary energy actually consumed, or that is expected to be required to meet the different energy needs with standard use of the building, such as winter and summer conditioning, domestic hot water production, ventilation and, for the tertiary sector, lighting, lifts, and escalators systems in the sector of construction industry trends.

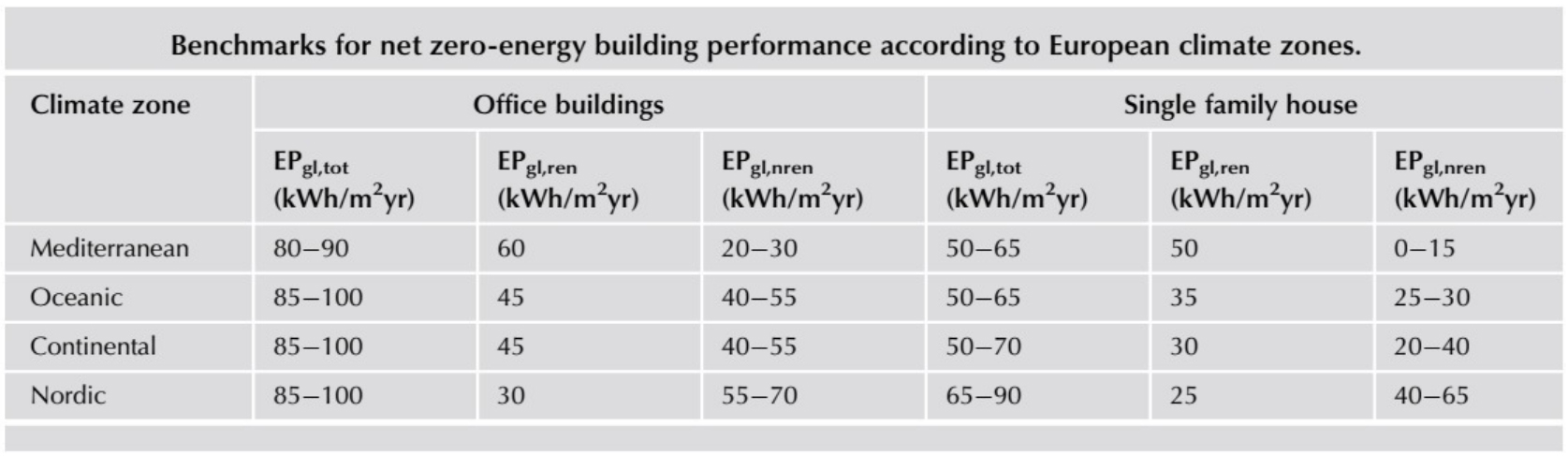

Global energy performance, as well as that of individual energy and transport services of the building, is generally measured by performance indexes (EPgl, tot) expressed in total annual primary energy per area unit in the sector of construction industry trends.

According to the definition, the transition from a reference conventional building toward a zero-energy building should follow two main strategies, the reduction of the energy demand (EPgl, tot) using energy-saving techniques, and the increase of energy supply from renewable energy taken from the grid or produced on site or nearby (EPgl, ren).

Design and construction of a ZEB require therefore a comprehensive approach to promoting rational use of energy by reducing energy requirements, installing high-efficiency systems, and using renewable energy sources through an optimal balance of passive and active measures in the sector of construction industry trends.

Buildings, being usually connected to an external network for the supply of energy such as electricity and gas, and considering the discontinuous nature of renewable energy sources (available only for certain times of the day), lead to a scenario where what is actually equal to zero is not the consumption of nonrenewable primary energy, but the balance between primary energy taken from the grid and the self-produced one.

in the sector of construction industry trends, if the production of renewable energy actually exceeds the needs of the building, they are called Net Plus Energy Buildings or Net Positive Energy Buildings. For these buildings, the difference between the energy demand (EPgl, tot) and renewable energy supplied (EPgl, ren), is almost equal to zero or negative.

2. Life Cycle Assessment (LCA) for Green Buildings

Researchers who wanted to apply strictly scientific criteria to the hesitation of resource consumption, particularly with regard to energy ones, realized that the simplest means to study production systems in a comprehensive way was to assess performance by following the entire path taken by raw materials initially with their extraction from the earth, through all the transfer in the sector of construction industry trends.

The American Environmental Protection Agency (EPA), as well as multiple British bottle manufacturers, utilized LCA as a decision support tool in the early 1970s, which is when the first evidence of its utilization can be found. In order to more accurately describe the mission of the assessments in the sector of construction industry trends, performed up to that point under the name “Resource and Environmental Profile Analysis” (REPA), the word “LCA” was first coined in 1990 during the SETAC congress.

With the support of the ISO 14040 series standards, the LCA method was subsequently established in 1997. Its definition is the “compilation and evaluation, throughout the life cycle, of the incoming and outgoing flows, as well as the potential environmental consequences, of a product system.”

The core application of LCA concerns product-related decision support in the sector of construction industry trends. It can include hotspot identification, product development, product comparison, green procurement, and market claims. Next to other tools, LCA is also important for technology choices, contextualizing them into a product-related chain perspective. LCA is increasingly used at a strategic level for business development, policy development, and education in the sector of construction industry trends.

3. Building Information Modeling (BIM)

At the base of the digital transition that is affecting the AECO sector, there is, first of all, the adoption of BIM, increasingly identified by policymakers and investors as a decisive strategic factor for the full control of all phases of the building process and for the achievement of quality and cost reduction objectives in the sector of construction industry trends.

Namely, BIM is a collaborative process in which all parties involved in the project use 3D modeling applications which integrate geometry with additional information about assets’ scheduling, cost, sustainability, operations, and maintenance in the sector of construction industry trends. This way, BIM ensures information is shared accurately and consistently throughout assets’ life cycles.

Differently from 2D and 3D CAD modeling, in fact, BIM allows to virtually construct of the building, before its actual erection, simulating its performance, construction times, and costs and thus providing essential information for achieving the set objectives in the sector of construction industry trends. The term BIM in fact indicates “the use of a shared digital representation of a built object in order to obtain a reliable basis for decisions that can facilitate the design, construction, and management processes” (ISO 19650:2019).

The BIM workflow entails a virtual information model to be handed from the design team to the main contractor and subcontractors and then on to the owner/operator and to the appointed facility manager in the sector of construction industry trends.

4. Cloud and Edge Computing

Another technology that is giving a significant boost to the digitalization of the construction sector is Cloud computing, which uses by design studios and companies and is steadily expanding. Eighty-five percent of construction contractors used or planned to use cloud-based solutions in 2017, from only 16% in 2012 (The Associated General Contractors, 2018).

After deeply evolving various industrial sectors in the last years, cloud-computing technologies are making their way into the construction sector as well due to the numerous benefits they can bring in all phases of the construction process, from design to construction, to management and maintenance.

Cloud services come in three main models: Infrastructure, Platform, and Software-as-a-Service in the sector of construction industry trends.

The IaaS model makes hardware resources available via the internet for storing, backing up, and restoring data, for hosting websites and apps, and for carrying out computational activities that require large computing capacities in the sector of construction industry trends. IaaS allows customers to avoid the upfront expenses of purchasing, configuring, and managing a local data center and allows rapid and cost-effective flexibility and vertical scalability for the creation of development and project management environments.

The PaaS model provides a web platform that, in addition to including the hardware infrastructures of the IaaS solutions, also provides users with middleware, development tools, business intelligence (BI) services, database management systems, and more, allowing users to avoid the upfront expense and complexity of separately purchasing these tools and managing them in the sector of construction industry trends. Examples include Amazon Web Services (AWS), Microsoft Azure, and Oracle PaaS platforms.

Finally, the SaaS model offers programs on the cloud that perform their tasks through Internet connections rather than working locally on computers following installation. Both apps and data are stored on private cloud services and accessed through a virtual desktop environment. This allows users to access the application from anywhere in the world and from any device connected to the internet and to work jointly on a single centralized document in the sector of construction industry trends.

SaaS examples include industry-specific tools for design such as BIM cloud (BIM 360), project management (Primavera, Oracle Financials, Procore, SmartnetBid), or other business applications such as customer relationship management (CRM), enterprise resource planning (ERP), and document management in the sector of construction industry trends.

5. Internet of Things (IoT)

A significant trend within the current digital revolution is that the cyber and physical environments are becoming more and more interconnected at different levels due to the diffusion of IoT, the infrastructure of devices and objects that are connected to the internet and can gather and transmit data on their particular state which can be collected for monitoring, control, statistical analysis, and decision support in the sector of construction industry trends.

The architecture of IoT allows to equip all objects with identifying, sensing, networking, and processing capabilities: these “smart objects” become able to exchange and share information and develop advanced services over the Internet. Interconnection of the distributed IoT network can facilitate deeper insight into complex systems and provide dynamic, context-aware decision-making capabilities and intelligent autonomy.

The wide application of sensors and wireless communication technologies to objects, machines, and people is allowing to generate real-time information on their particular state which can be collected for monitoring, control, statistical analysis, and decision support both in construction, operation, and maintenance phases of the building, up to the possibility of creating a digital replica of the building. Information sharing can take place directly machine-to-machine, allowing devices to communicate and interact even without human intervention.

IoT technologies are also the basis of the creation and diffusion of smart buildings and smart homes. IoT devices can in fact be integrated into all systems and equipment inside buildings (electrical distribution, air conditioning, lighting, data network, access control, fire and security systems and energy storage etc.) or in building envelope elements such as doors, windows or shielding systems, contributing substantially to save energy, improve comfort and safety conditions and promote more sustainable users’ habits and choices in the sector of construction industry trends.

By analyzing the collected environmental and activity data and using predictive models, the building’s IoT network allows the building automation systems (BASs) to take into account the external climatic conditions, the energy costs of the network, the actual presence of users and their preferences, thus maximizing the conditions of comfort and at the same time reducing the energy consumption of the building in the sector of construction industry trends.

6. 5G Network

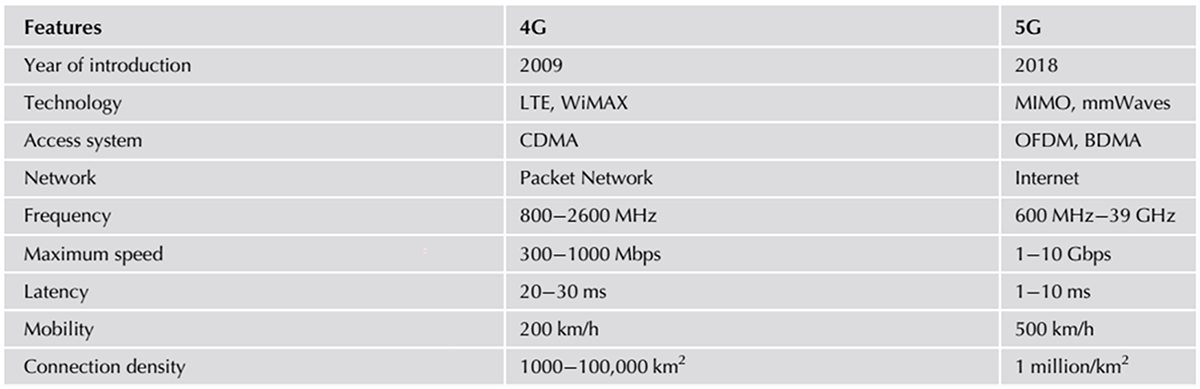

The term “5G” broadly indicates the fifth-generation technology standard for broadband cellular networks that began deploying worldwide in 2019 in substitution of the current 4G network introduced in 2009. While earlier transitions to next-generation networks, from 1G to 4G, mainly boosted cellular communications mostly by speeding up service and increasing bandwidth, the current transition to 5G promises an even greater impact on society by providing a key platform for cutting-edge applications for industry 4.0 and smart city, way beyond faster smartphones.

The main advantage of the new 5G cellular networks, compared to the 4G standard, is that they present greater bandwidth, giving higher speeds (with theoretical values from 1 up to 10 Gbit/s in download compared to the 300 Mbps1 Gbps of 4G LTE), a lower latency time (only 812 ms), the ability to manage a greater quantity of devices per unit of surface area (approximately 1,000,000 devices/km2 against 1000100,000/km2 of 4G), a significant reduction in consumption energy (90% less than 4G for each bit transmitted), as well as the ability to support even devices in motion at very high speeds (approximately 500 km/h).

The characteristics of high speed, high reliability, low latency, high connection density, and security, typical of the 5G network, make this technology crucial for the creation of increasingly smart and connected construction sites and for the full application of advanced construction tools and methods in the sector of construction industry trends.

To improve the quality, efficiency, and safety of construction, there is a growing need to leverage the new digital technologies of virtual design and construction (VDC), XR, AI and advanced analytics, cloud computing, image capturing, and teleoperated machines which, however, require a fast and reliable transmission of a large amount of data.

7. Automating Construction Process Technologies

The automation of construction processes refers to the use of digital manufacturing techniques, including formative, subtractive, and additive methods, and robots and autonomous or teleoperated vehicles to automate specific tasks or processes in both on-site and off-site fabrication activities. The benefits achievable consist of increased efficiency, greater precision, and improved workplace safety and security in the sector of construction industry trends.

Digital fabrication processes such as CNC machines, robots, and 3D printing can reduce construction time and costs, as well as achieve shapes with optimized performance/material ratio. Advancement in digital fabrication is also showing enormous potential in terms of new architectural possibilities, precise material processing, structurally effective shapes and graded assemblies, and a lower environmental footprint of construction in the sector of construction industry trends.

This type of industrialized process allows to digitally link execution to BIM and CDE so that instructions can be seamlessly delivered for physical production.

8. Big Data and Advanced Analytics

The term “Big Data” refers to the exponential explosion in the amount of data being generated and stored at any moment in this increasingly digital age, while “advanced analytics” refers to the ability to automatically work with and generate insights from these data.

Advanced analytics involves using AI and ML to automate analytics processes, including gathering data from raw data sources, preparing and cleaning that data, building unbiased analytics models, and generating and communicating relevant insights to those who request them.

Big Data analytics offer insights that traditional systems simply cannot, providing helpful indications concerning accurate budget estimates, risk levels associated with thresholds for alerts, the scheduling of the optimal time to start works, the best combination of equipment purchase and rental, how to use fuel more efficiently to reduce costs and environmental impact, and more in the sector of construction industry trends.

9. Nanotechnology

Nanosciences constitute a whole new approach to research and development, aimed at controlling the structure and fundamental behavior of matter at the atomic and molecular levels. In particular, nanotechnology is defined as the application of scientific knowledge to manipulate, control and synthesize matter in the nanoscale (from approximately 1 to 100 nm). The nanometer (nm) equals 10-9 or a billionth of a meter, a dimension tens of thousands of times smaller than the thickness of a human hair and correspondent to the length of a small molecule.

In the construction sector, the use of nanotechnology can bring many benefits by improving the energy and environmental performance of buildings, with application potential in all technical elements, from structures to opaque and transparent closures, internal partitions, to systems and appliances in the sector of construction industry trends.

Several solutions are already available to increase the mechanical, physical, and chemical properties of materials, products, and equipment, as well as their durability over time, with the aim of improving environmental comfort, safety, and energy efficiency of buildings and at the same time reduce operating and maintenance costs and environmental impacts.

Nanotechnology finds application in all main construction materials, elements, and systems of buildings including structural materials such as steel, wood, or concrete; plasters and screeds; construction ceramics; plastics and polymers; insulating materials; glazing; paints and coatings; adhesives; lubricants; energy storage systems; renewable energies; building and environmental monitoring and control systems in the sector of construction industry trends.

Within these construction materials, elements, and systems, nanomaterials can be integrated with the form of solid nanocomposite materials, solid materials enhanced with nanocoatings or characterized by nanostructured surfaces, nanoporous materials, and fluid nanodispersion as nano paints, nano adhesives or nano lubricants in the sector of construction industry trends.

10. Virtual Reality (VR) Technologies

Virtual reality (VR) is the name given to computer technologies that employ software to produce lifelike pictures, sounds, and other sensations that depict an immersive environment and simulate a user’s actual presence by allowing in-the-moment interactions through sensorimotor channels.

Currently, the development of tools, parts, software, and user interfaces is advancing quickly, and many top manufacturers, including those in the AECO sector, are implementing these technologies. Virtual reality (VR) has been promoted as a tool to simplify design, engineering, construction, and management for the built environment due to its sophisticated immersive and interactive visualization capabilities in the sector of construction industry trends.

VR is a particularly effective tool for design teams, contractors, and owners to review and approve plans and comprehend sites and spaces because it offers a completely immersive experience. The user’s entire environment is under the control of the VR application, which results in a richly detailed and dynamic experience in the sector of construction industry trends.

In general, the hardware of a VR system can be classified into three types based on their use, namely, display devices, motion capture (mocap) devices, and interactive devices. A display device is the essential element of a VR system, which outputs stereoscopic images to users.

Display walls, HMDs, and portable devices are three commonly used types of display equipment. Generally, the typical VR platform can be categorized into three paradigms in the sector of construction industry trends:

Head-based: a head-based VR device is a helmet or head-mounted display where graphic images are displayed on a screen or a pair of screens, one for each eye, while a position-tracking sensor is embedded to respond to where the user is looking;

Stationary: the stationary VR platform is usually fixed in place and uses projectors and/ or large display screens to display the visual information of the experience;

Hand-based: the hand-based VR paradigm refers to the device that the participant can hold with their hands and hold up to their eyes, such as a smartphone or tablet.

Numerous studies confirm that copresence through VR strengthens the sense of collaboration among team members, especially in terms of social aspects such as dependencies, encouragement, and mutual learning from each other, in comparison with other forms of remote collaboration in the sector of construction industry trends.

Suggested article for reading: The 7 Benefits of Virtual Reality in Construction

11. Smart Coatings

The application of advanced coatings in buildings, such as transparent or opaque paints and thin films, allows to improve mechanical, physical, and chemical performances of building materials and components by imparting their new properties, both fixed (antireflection, scratch resistance, UV resistance, water resistance, etc.) and dynamic (chromogenic, self-cleaning, self-healing, luminescence, antibacterial, etc.).

Thanks to specific surface treatments of building elements in the construction phase, today is in fact possible in the sector of construction industry trends:

- make surfaces active in contributing to the maintenance of requirements of hygiene and health (air-purifying, self-cleaning, antibacterial);

- improve thermal behavior of the building envelope making the surfaces reflective of sun radiation or internal infrared radiation (thermal responsive);

- make surfaces active in light emission (photo luminous);

- improve surfaces’ response to external environmental wear, making them more resistant to corrosion, abrasion, impacts and scratches, solar ultraviolet radiation, water, and fire, and even able to repair themselves (self-healing).

12. Data Acquisition Technologies

Data acquisition technologies, namely aerial mapping, 3D photo reconstruction, LiDAR scanning, wireless sensors networks, and IoT, are the starting point for the digitalization of the construction sector, as they provide most of the data necessary for the virtual migration of physical structures and to build and develop the digital construction ecosystem in the sector of construction industry trends.

Aspects of the construction, from geo-localization to operational status, to environmental parameters to energy usage, up to image and video recordings. Such unprecedented availability of data will allow for a growing range of analytical services to improve productivity in all phases of the construction process and its subsectors.

Collected data can be fed to digital twins and to advanced analytics to gather relevant information and assess ways to optimize site operations: for example, fuel spending and energy usage, utilization rates of machines and equipment, location of storage, and workstations to reduce clashes and nonproductive movements. In this context, sensors can contribute to creating a more efficient supply chain, and hence improve the timelines of projects and foster better communication with clients in the sector of construction industry trends.

13. 3D Printing

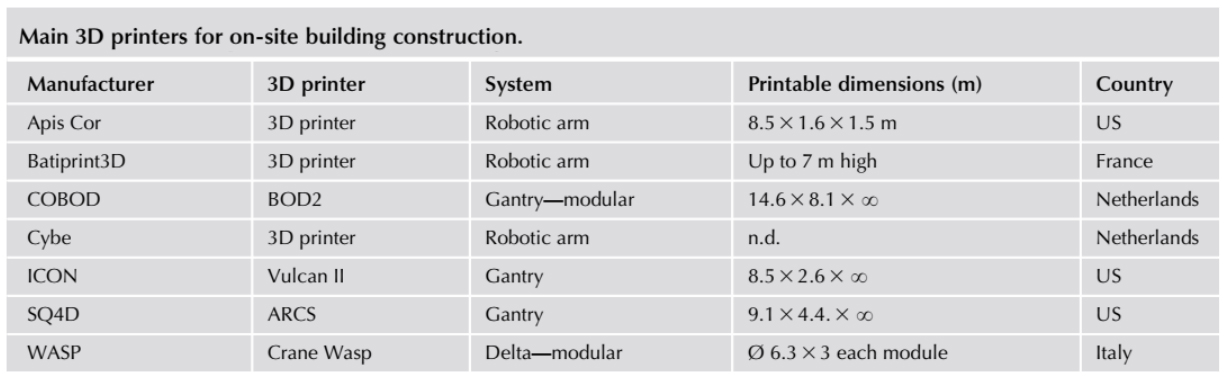

Over the past five years, the 3D printer market has experienced substantial growth. By the end of 2020, there will be more than 2000 various 3D printer models available on the market, made by more than 600 companies located in more than 30 different nations, evenly split between the US, Asia, and Europe. There are Currently 42% of printer models geared at the professional market, 37% at the industrial market, and 21% at the consumer market.

Nowadays, 3D printers are able to achieve dimensional accuracy, surface roughness, and improved mechanical properties well suitable for end-use products. Additionally, significant developments in materials have provided 3D printing technology a platform for material science which allows researchers and scientists to adapt material deposition and anisotropic behavior and active sensing based on surrounding environments in the sector of construction industry trends.

3D printing can be carried out using numerous types of materials with the aim of creating models, molds, or end-use objects (DDM). 3D printing feedstock can come in filaments, wire, powder, resin, paste, ink, or sheets form depending on the 3D printing processes used. According to ISO/ASTM 52900, materials for AM can be categorized as polymer, metallic, ceramic, and composite, with composite materials defined as any combination of the other material categories in the sector of construction industry trends.

An example of a large-scale delta 3D printer is the 12 m high Big Delta developed by Italy-based WASP, considered to be the biggest 3D printer available. The experience gathered with Big Delta was reinvested in developing the Crane WASP modular printing system, which can be assembled in different configurations according to the printing area, and is able to print single modules up to 6.6 m in diameter and 3 m in height in the sector of construction industry trends.

Crane WASP was used to fabricate Gaia, a sustainable housing unit built using a mix of 25% earth from the construction site, 40% rice chaff, 25% rice husk, and 10% hydraulic lime. The house features a 3D-printed foundation layer and a 40 cm thick engineered envelope that integrates ventilation chambers, housings for systems, and thermal insulation that was printed over 10 days totaling 22 km of extruded filament.

Suggested article for reading: 3D Printing in Construction

14. Smart Contracts and Blockchain

The construction sector has in fact several issues regarding its reputation, such as a lack of trust, being unfair to subcontractors, and a slow rate of change in comparison with other industries. Transactions between all actors involved in construction therefore still rely on a network of intermediaries, middlemen, women, and go-betweens whose job is to verify and vouch that the other party is trustworthy by gathering information and developing professional networks in the sector of construction industry trends.

Smart contracts are one of the proposed solutions to streamline the current financial/legal environment of the construction industry trends. The term “smart contract” was coined by Nick Szabo in 1994 and is defined as a computer program that secures, enforces, and executes the settlement of recorded agreements between people and organizations with an if/ then structure that administers the contract clauses in the sector of construction industry trends.

The advantages of such a system are its clarity and enforceability, which may result in smoother contract execution and a significant reduction in disputes. The general objectives of smart contract design are to satisfy common contractual conditionals (such as payment terms, liens, confidentiality, and even enforcement), and minimize the need for intermediaries. Related economic goals include lowering fraud loss, arbitration and enforcement costs, and other transaction costs in the sector of construction industry trends.

Suggested article for reading: Blockchain in Construction

15. Drones

The term UAV or drone encompasses a class of variously sized aircraft that may be remotely controlled or can fly autonomously, without the onboard presence of pilots. More correctly, the aircraft itself is just a part of the unmanned aircraft system (UAS), which also includes the other elements required for flight such as ground control stations, data links, and other support equipment. Commonly used alternative terms for UAS are unmanned-aircraft vehicle system (UAVS), remotely piloted aerial vehicle (RPAV), or remotely piloted aircraft system (RPAS)

Established civil uses of UAVs include aerial photography, aerial crop surveys, search and rescue, an inspection of power lines and pipelines, wildlife monitoring, emergency delivery of medical supplies, forest fire detection, surveillance, plume tracking, post-disaster investigation, and crowd monitoring. UAVs have demonstrated their utility in the construction industry trends as well, and in site management in particular, providing important benefits in land surveying, worksite supervision, and inspection of buildings and infrastructure in the sector of construction industry trends.

A professional UAV can rapidly collect all the data required to generate a highly accurate 3D building model (including colors, rooftops, external areas, etc.) which can be used to update the construction site’s digital twin and compared to the project’s BIM model to recognize the current as-built conditions of a project efficiently, to identify disparities between the as-built and as-planned progresses, and to aid in deciding on corrective actions.

Aerophotos can be overlaid on design plans on a daily basis to check worksite progress at a glance and minimize the need for reworks. Real-world scenarios can then be simulated to catch any discrepancies that would be costly if they were not identified until later, such as crane positioning and movement.

Suggested article for reading: The Importance of Drones in Construction

16. Digital Health Tracking

Due to the nature of the construction industry trends, where the design team and contractor seldom work together at the early stages of design conceptualization, there is still a massive gap in awareness of safety issues among designers. There is a valid argument that some construction safety issues resulting from the lack of safety awareness at the design stage.

Over the last decade, there has been a steady growth in the number of digital solutions to onsite health and safety challenges. Digital technologies such as AR, VR, BIM, cloud computing, blockchain, IoT, and robotics, are applied for construction health and safety in the sector of construction industry trends.

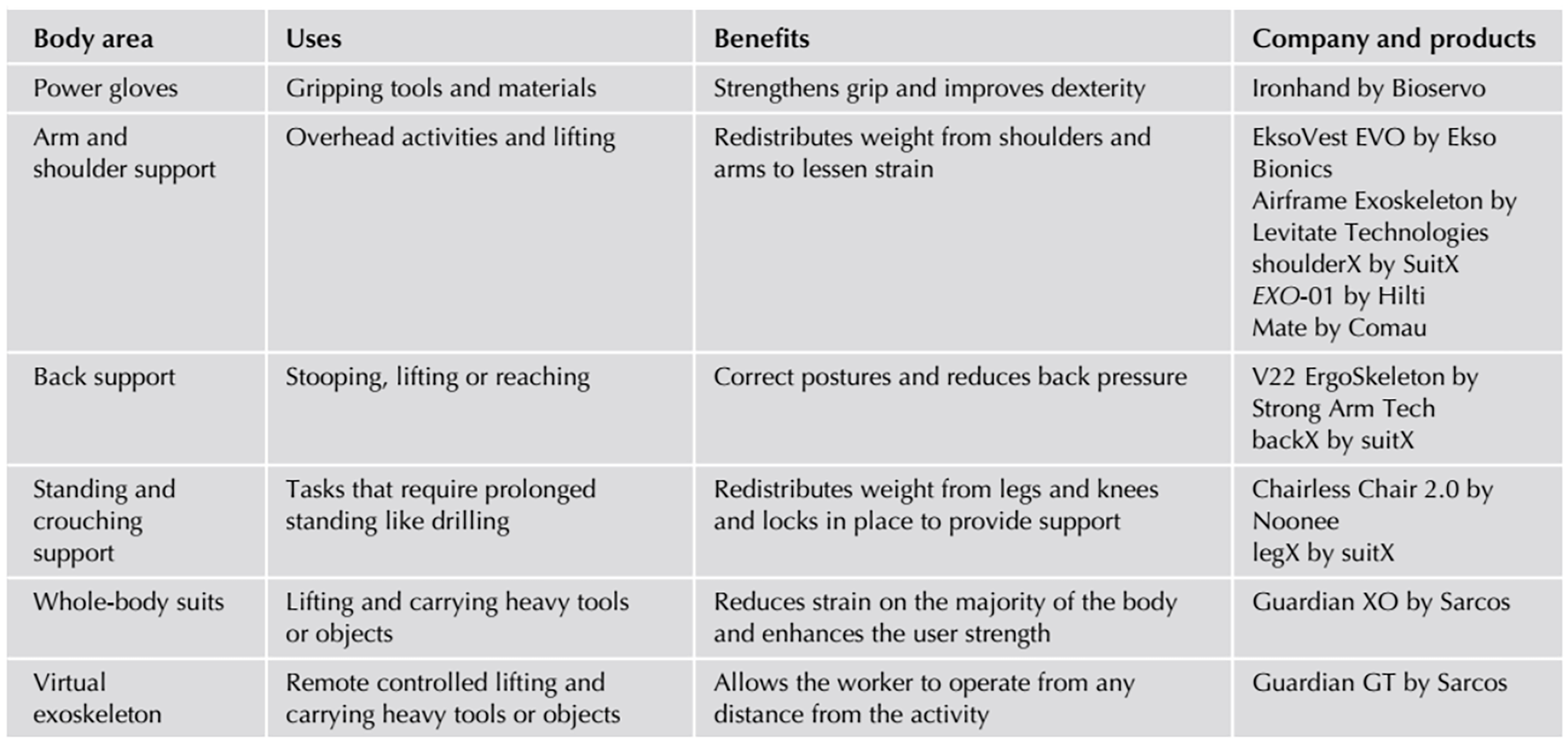

For instance, the use of exoskeletons, that is, robotic body devices worn by the worker, can improve performance and significantly reduce safety risks when doing tasks such as lifting heavy loads, or using equipment in uncomfortable positions. These devices can be also equipped to conduct musculoskeletal stress monitoring, so as to regularly measure the worker’s physical conditions.

This is of particular relevance in the construction sector, where, according to the European Agency for Safety and Health at Work, 52% of construction workers report backaches, 54% show musculoskeletal disorders in the upper limbs, and 41% show them in the lower limbs.

Robots can also be used to automate traditionally manual activities, such as bricklaying, excavation, or wall painting, by being combined with other technologies, for example, sensors, drones, and BIM, to execute the task without the need for physical human presence in the sector of construction industry trends.

17. White-Box Method

White-box method models the thermal dynamics and energy behavior of a building or sublevel components by calculation, based on either the physics of buildings or suitable approximations thereof. One of the main advantages of white-box methods is that the system does not require to be physically built or to provide historical data to evaluate its performance, making them suitable for preliminary predictions of energy needs and the design of system loads. Historical data from the field may in turn be used to calibrate the white-box model and improve its accuracy in the sector of construction industry trends.

Nonetheless, the common approach to developing white-box models is to employ one of the building energy simulation software programs available on the market, which were initially built for design purposes to simulate energy and mass flows in buildings according to the envelope materials, the weather, the internal loads, and the HVAC systems based on detailed models of building components in the sector of construction industry trends. However, these are typically not directly suitable for integration into the MPC as a prediction model, for the following main reasons:

1. They often focus on a single subsystem, such as the building envelope, the HVAC system, or the on-site energy generation, and struggle to integrate different functions into the same simulation problem;

2. They are typically non-equipped to perform optimization problems internally and need external algorithms and tools to process their results;

3. Simulation output is commonly non-compatible directly with typical supervisory and control sequences for building automation.

18. Hydrogen Role in Decarbonization

Hydrogen is a clean energy carrier that can play an important role in the global energy transition toward zero carbon since important synergies exist between the accelerated deployment of renewable energy and hydrogen production and use in the sector of construction industry trends.

Hydrogen can positively contribute to decarbonization in several ways:

- it can help tackle various critical energy challenges by offering ways to decarbonize a range of sectors—including intensive and long-haul transport, chemicals, and iron and steel—where it is proving difficult to meaningfully reduce emissions. It can also help improve air quality, strengthen energy security, and increase flexibility in power systems;

- it is a free energy carrier that can be produced by many energy sources, therefore versatile in terms of supply and use;

- it can be used to produce synthetic fuels—methanol, jet fuels, methane, and other hydrocarbons—through chemical processes with a carbon source (CO and CO2) captured from emission streams, plants, and animals or directly from the atmosphere, which in turn can be used to directly replace their fossil-based counterparts. Synthetic fuels produce carbon emissions when combusted, but if their production process consumes the same amount of CO2, in principle this allows them to have net-zero carbon emissions;

- it can enable renewables to provide a greater share of the energy supply by mitigating their variable output, such as PVs and wind power. Hydrogen is poised to become a low-cost option for storing large quantities of electricity over days, weeks, or months and even transporting it over long distances.

As reported, almost all hydrogen is still produced from fossil fuels, from methane using steam methane reforming (SMR) or coal gasification, without CO2 capture (so-called gray hydrogen). Although the cheapest solution for hydrogen production today, it is not sustainable for a route toward net-zero emissions: hydrogen from SMR has an emission factor of around 285 grams of CO2 per kWh, and coal gasification has an emission factor of around 675 grams of CO2 per kWh, accounting only for energy use and process emissions.

Regarding the building sector, hydrogen has several potential applications with different advantages and infrastructure requirements. A low-investment method to support the energy transition is the addition of hydrogen to gas already used for building heating (blending ratios between 5% and 20%), or its replacement with methane entirely produced from clean hydrogen. Both allow to maintenance of the current gas networks and equipment, but full decarbonization can be achieved only by using gas from low-carbon hydrogen and low-carbon CO2 inputs in the sector of construction industry trends.

19. Digital Twin

With the increasing diffusion of BIM and IoT devices, the future of building O&M is represented by DT technology, which promises to revolutionize the way buildings are managed and maintained by transforming them into a rich ecosystem of data and insights.

The term “digital twin” refers to a digital replica of a physical entity—a product, a service, a process, or even a living being—which is continuously informed by live data collected from sensors within the real structure it replicates, thus pairing the virtual and physical worlds with the two-way dynamic mapping between the physical object and its digital model.

The objective of the DT technology is to provide an accurate and up-to-date virtual model for any physical entity, on which to simulate entity behaviors, monitor the ongoing status, recognize internal and external complexities, detect abnormal patterns, reflect system performance, predict future trends and optimize operation. Predictions and what-if scenarios can be conducted on the DT to see what might happen if adjustments are made that might be too expensive, dangerous, or uncertain to try out in a real-world scenario.

By altering the variables under which the DT is operating, the changes can be observed in the digital world without putting money or safety at risk, allowing a much larger space for trial and error and experimentation. Although both DT and abstract simulation can execute replications in cyberspace, they are not the same as DT relies on actual, real-time data from its physical counterpart, whereas simulation is based on the study of mathematical models.

20. Use Exoskeletons for Occupational Safety

The integration of robotics and automation into construction site activities, with the aim of increasing productivity and reducing time, cost, and safety issues for workers, does not strictly translate to replacing human labor. On the contrary, much of robotics and bio-mechanic science is currently being applied also to ease the working conditions of human labor by directly enhancing their physical capability by means of wearable electro-mechanical devices known as exoskeletons, thus allowing human augmentation of the workforce in the sector of construction industry trends.

Exoskeletons are wearable mechanical devices, passive or powered, that aim to minimize strain and injury by providing lift support, weight distribution, posture correction, and other capabilities. Initially conceived for physical rehabilitation, these equipment are being increasingly used by workers in manufacturing, logistic, and recently also in construction.

Exoskeletons can help workers by allowing them to lift heavy loads, reduce fatigue, facilitate the use of tools in awkward positions, etc., reducing the impact of each task and improving their productivity, resulting in a healthier workforce less prone to severe strain, injuries, and permanent disabilities normally associated with repetitive, physically demanding tasks. Exoskeletons can also allow older workers to continue their on-site activities, mitigating the issues associated with the aging of the construction workforce in the sector of construction industry trends.

Despite these benefits, several challenges are still to be addressed before exoskeletons are more widely adopted. In addition to industry-wide issues that include high costs, energy efficiency, safety, and comfort, the construction sector poses the following barriers to exoskeleton use:

- health and safety concerns regarding increased risks of catching, snagging, and falling, hygiene issues, and a false sense of safety;

- usability concerns regarding the ruggedness expected from exoskeletons to adapt to the harsh conditions of the construction site while remaining comfortable and safe to use;

- integration with other personal protective equipment (PPE);

- high initial costs of adoption;

- possible low acceptance rates by workers.

21. Construction Safety Management Visualization with 4D BIM

The fourth industrial revolution (4IR), is expected to bring simultaneous accelerated development to industries all over the world due to the current tendency of fast technology spread through globalization.

The construction manager plays a major role in promoting a safer work environment as a major player in the management hierarchy. The proficient planning of dynamic daily activities, proper allocation of resources, and identifying safe work behavior are vital aspects of safety management. Facilitating the improvement of the safety skills of employees who are responsible for people management supported by relevant technology is a practical way of improving the safety performance of a construction site.

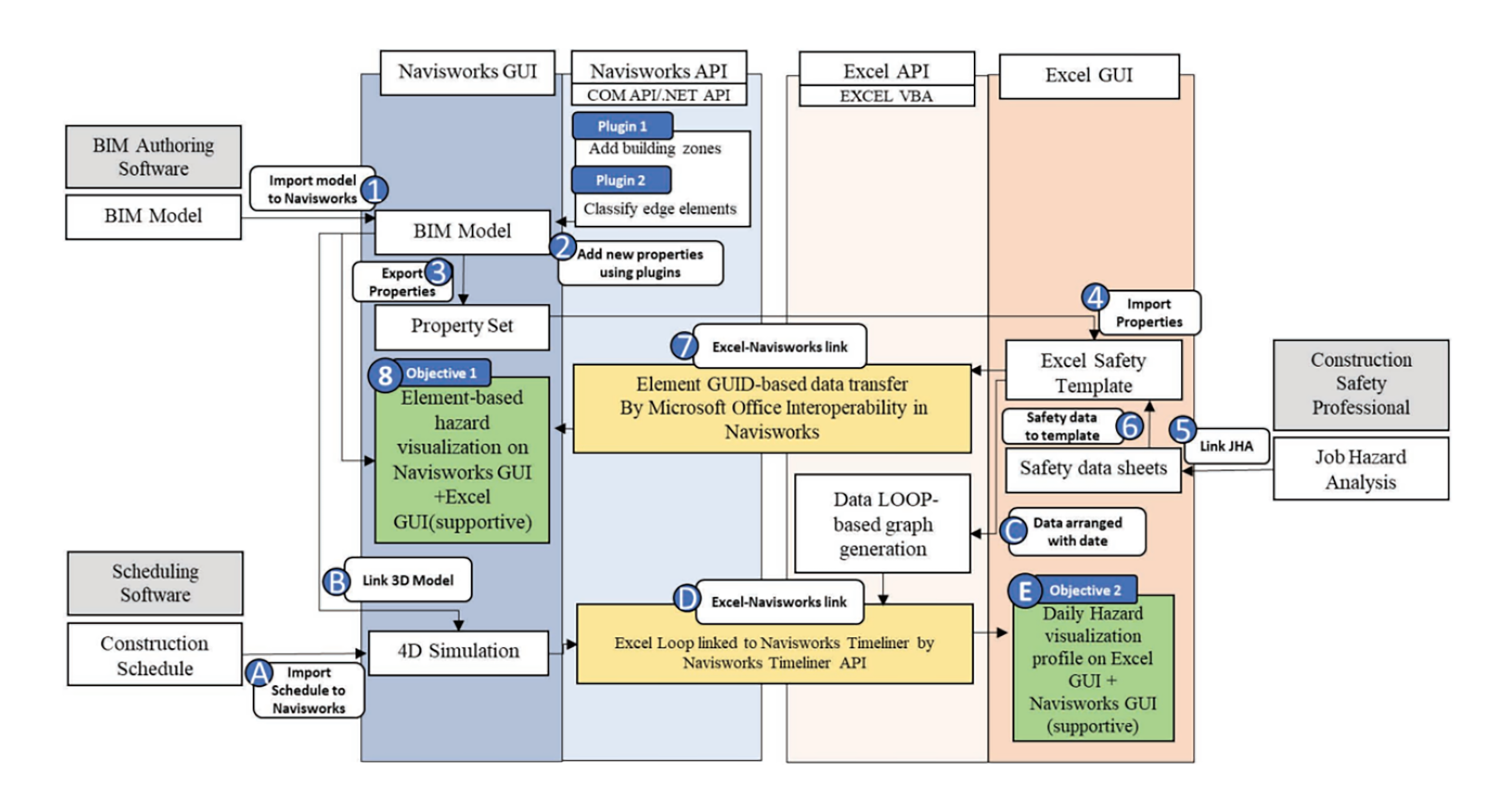

Implementation of BIM-based safety management workflows and the investment in BIM-capable human resources are vital aspects of construction safety management enhancement in the sector of construction industry trends.

A 4D BIM model is a well-received approach in construction project management for preventive safety management as an existing routine tool due to its ability to increase project visualization and increase safety collaboration and communication between multiple stakeholders, thus reducing safety risk by supplying the ability to foresee hazards.

The addition of object-oriented automated safety rule checking to 4D BIM is effective in further hazard identification and prevention. Thus, the current studies aim to accommodate a proactive hazard suggestion system with 4D BIM to effectively suggest possible hazard occurrences on an element and project timeline basis.

Future Perspectives on Construction Industry Trends

Future decades will see a tremendous revolution in the construction sector as it adopts innovative technologies and changes its approach to meet shifting consumer needs. The growing adoption of eco-friendly and sustainable approaches is one of the major factors that will influence its future in the sector of construction industry trends.

Construction firms are projected to give priority to energy-efficient building designs, the use of renewable resources, and the use of green construction techniques as worries over climate change and environmental conservation grow. In addition to being in line with global objectives, this move toward sustainability also offers new prospects for construction industry trends to grow.

The use of data-driven decision-making processes and a move towards digitization will both be seen in the future of the construction sector. Construction firms are becoming more and more aware of the use of data in enhancing project outcomes and operational effectiveness. Building information modeling (BIM), cloud computing, and Internet of Things (IoT) sensors are just a few examples of the technology that construction companies may use to collect and analyze massive volumes of data throughout the project’s lifetime.

Better collaboration, real-time monitoring of construction activities, and predictive maintenance are made possible by this data-driven methodology, which leads to quicker project completion, lower costs, and higher overall project quality.

In conclusion, revolutionary technologies, sustainable practices, and data-driven decision-making will influence the direction of the future in the sector of construction industry trends.

Adopting sustainability will not only address ecological problems but also generate new growth and differentiation potential. Digitalization and data-driven processes will enable better project results and operational efficiency, and the integration of technologies like AI, robotics, and automation will improve efficiency and safety. The construction sector may position itself for success in the dynamic and changing environment of the future by embracing construction industry trends.

Suggested article for reading:

The Top 7 Green Architecture Projects

important construction technology in 2024

7 Important Building Technology Ideas for 2024

Resources:

Forbes | ONIX | Clime Co | Safety Culture | TWI Global | Smart Coatings | CISCO | Autodesk | European Commission | New Climate Institute

– Construction 4.0_ Advanced Technology, Tools and Materials for the Digital Transformation of the Construction Industry

– Handbook of Construction Safety, Health and Well-being in the Industry

For all the pictures: Freepik